PVC pellet composition with low compression set, and preparation method and application thereof

A technology of permanent deformation and composition, applied in the field of PVC pellet composition and PVC pellet composition with low compression permanent deformation, can solve the problems of loss of sealing function, easy aging, high price, and improve durability and service life , reduce the effect of compression set

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040]The PVC pellet composition of low compression set in the present embodiment comprises the following components, and is based on every 100 parts by weight of PVC with other parts by weight in proportion:

[0041]

[0042] In addition, it also contains the following components, and the weight ratio based on 100 weight parts of PVC is:

[0043]

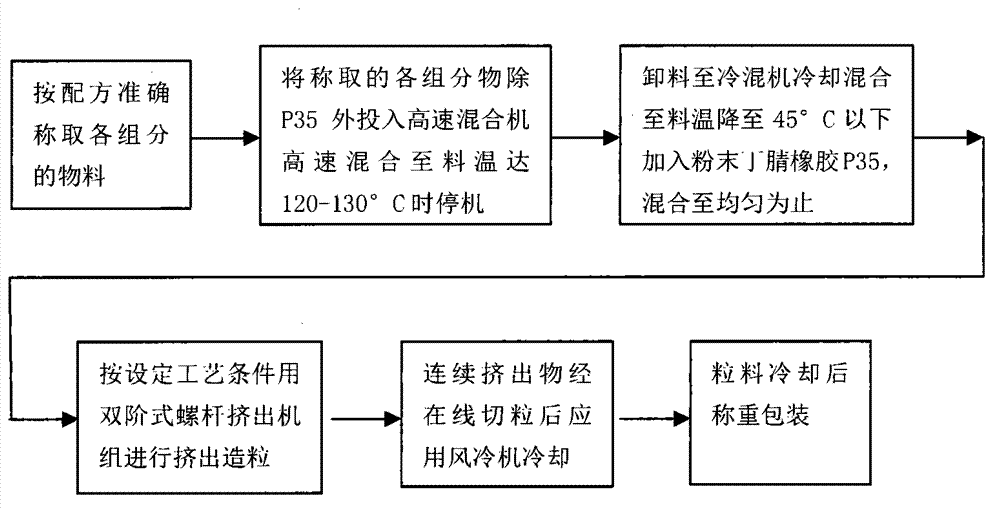

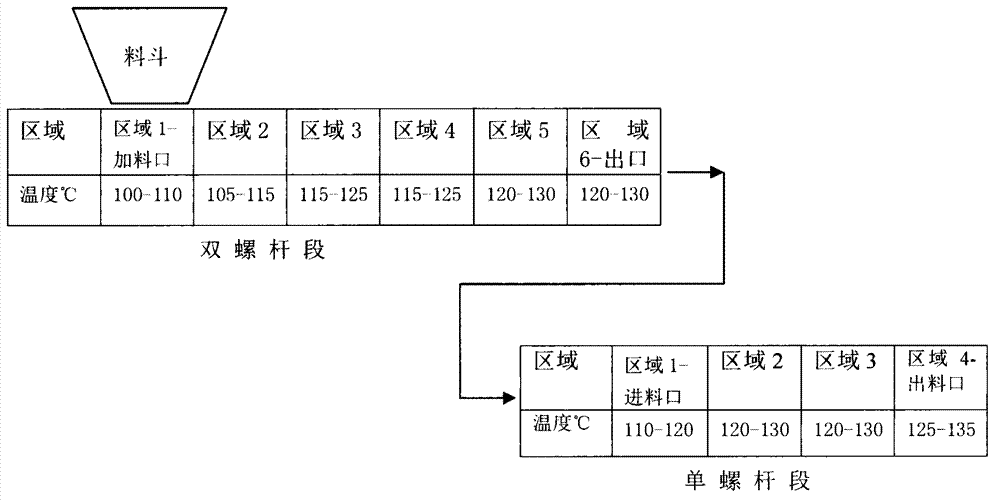

[0044] For its preparation process, see figure 1 , the specific steps are:

[0045] a. Calculate the required weight of each component according to the weight ratio, and weigh each component material according to the calculated result;

[0046] b. Put all components except powdered nitrile rubber into the high-speed mixer, start the machine for high-speed mixing, set the speed of the mixer to 800-1000 rpm, and when the temperature of the material in the machine reaches 120-130°C When, stop;

[0047] c. Transfer the hot material in the high-speed mixer to the cold mixer, start it up for cooling and mixing, and select the mi...

Embodiment 2

[0057] The PVC pellet composition of low compression set in the present embodiment comprises the following components, and is based on every 100 parts by weight of PVC with other parts by weight in proportion:

[0058]

[0059]

[0060] In addition, it also contains the following components, and the weight ratio based on 100 weight parts of PVC is:

[0061]

[0062] Its preparation method refers to Example 1.

[0063] After testing, its main performance indicators including compression set can also meet the requirements listed in Table 1. Because the present embodiment increases the amount of addition to the elastic modifier powder nitrile rubber P35, and reduces the content of the plasticizer diisononyl phthalate and epoxy soybean oil simultaneously, the purpose is to ensure the stability of the PVC modified pellets. The hardness remains basically unchanged, and the advantage of this embodiment is that the compression set performance is more excellent than that of t...

Embodiment 3

[0066] The PVC pellet composition of low compression set in the present embodiment comprises the following components, and is based on every 100 parts by weight of PVC with other parts by weight in proportion:

[0067]

[0068] In addition, it also contains the following components, and the weight ratio based on 100 weight parts of PVC is:

[0069]

[0070] Its preparation method refers to Example 1.

[0071] After testing, its main performance indicators including compression set can also meet the requirements listed in Table 1. Because the present embodiment has reduced the addition amount to elastic modifier powder nitrile rubber P35, increased the content of plasticizer diisononyl phthalate and epoxidized soybean oil simultaneously, purpose is to reduce the elastic modifier At the same time, it is ensured that the hardness of the PVC modified pellets remains basically unchanged; the advantage of this embodiment is that the material cost is relatively low. Since the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com