Environment-friendly PVC (Poly Vinyl Chloride) weld joint sealant for vehicle

An environmentally friendly and sealant technology, applied in adhesives, adhesive additives, and other chemical processes, can solve problems such as high curing temperature, inability to realize the "wet-on-wet" coating process, toxicity and harm, and achieve compatibility Good, excellent thermal stability and light stability, small migration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

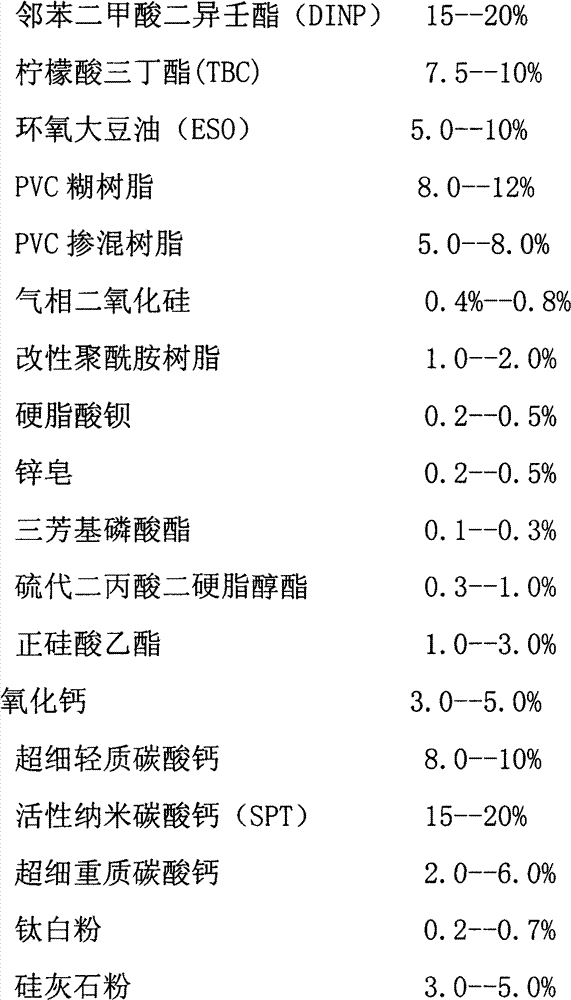

[0045] Viscosity is the formula of 6000mPa.s (by mass percentage):

[0046]

[0047]

[0048] The preparation method of environment-friendly type vehicle PVC weld sealant of the present invention is as follows:

[0049] (1) Add 110kg of PVC paste resin to 50kg of diisononyl phthalate, disperse into a uniform paste at high speed, and set aside.

[0050] (2) Take 12kg of modified polyamide resin and add it to 10kg of diisononyl phthalate, disperse evenly at high speed, and set aside.

[0051] (3) Take 3kg of titanium dioxide, 30kg of wollastonite powder, and 20kg of superfine aluminum silicate and add them to 20kg of diisononyl phthalate, disperse evenly at high speed, pass through a three-roller machine until the fineness is less than 60 μm, and set aside.

[0052] (4), get 5kg fumed silica, 2kg triaryl phosphate, 3kg distearyl thiodipropionate, 12kg tetraethyl orthosilicate, 30kg calcium oxide, 82kg superfine light calcium carbonate, 200kg active Add nanometer calcium ca...

Embodiment 2

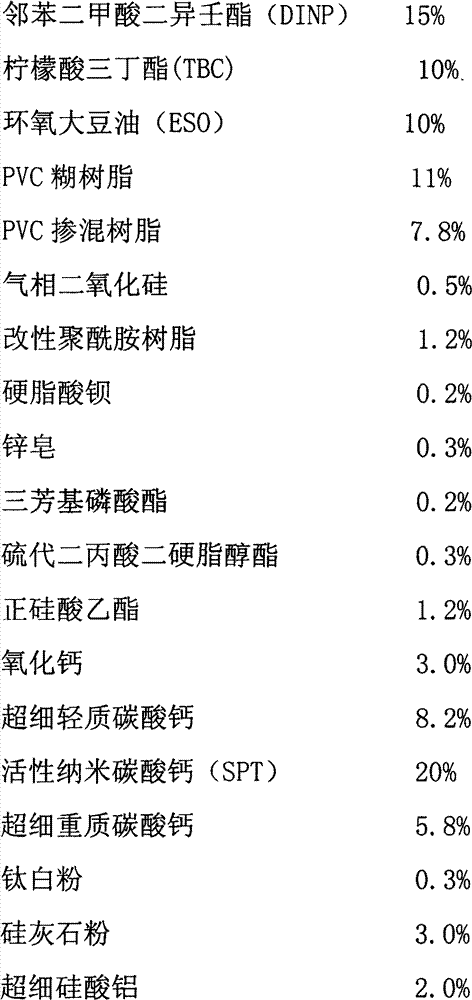

[0059] Viscosity is the formula of 9000mPa.s (by mass percentage):

[0060]

[0061]

[0062] The preparation method of environment-friendly type vehicle PVC weld sealant described in embodiment 2 is as follows:

[0063] (1) Add 80kg of PVC paste resin to 30kg of diisononyl phthalate, disperse into a uniform paste at high speed, and set aside.

[0064] (2) Take 20kg of modified polyamide resin and add it to 10kg of diisononyl phthalate, disperse evenly at high speed, and set aside.

[0065] (3) Take 7kg of titanium dioxide, 50kg of wollastonite powder, and 58kg of superfine aluminum silicate and add them to 50kg of diisononyl phthalate, disperse evenly at high speed, pass through a three-roller machine until the fineness is less than 60 μm, and set aside.

[0066] (4), get 8kg fumed silica, 3kg triaryl phosphate, 8kg distearyl thiodipropionate, 22kg tetraethyl orthosilicate, 50kg calcium oxide, 100kg superfine light calcium carbonate, 162kg active Add nanometer calcium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com