Military ground cloth and preparation method thereof

A technology of ground cloth and base cloth for military use, which is applied to devices for coating liquid on the surface, coatings, textiles and papermaking, etc. It can solve the problems of no preparation method, poor functionality, simple structure of tent cloth, etc., and achieve rapid preparation , easy to clean, and highly functional

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

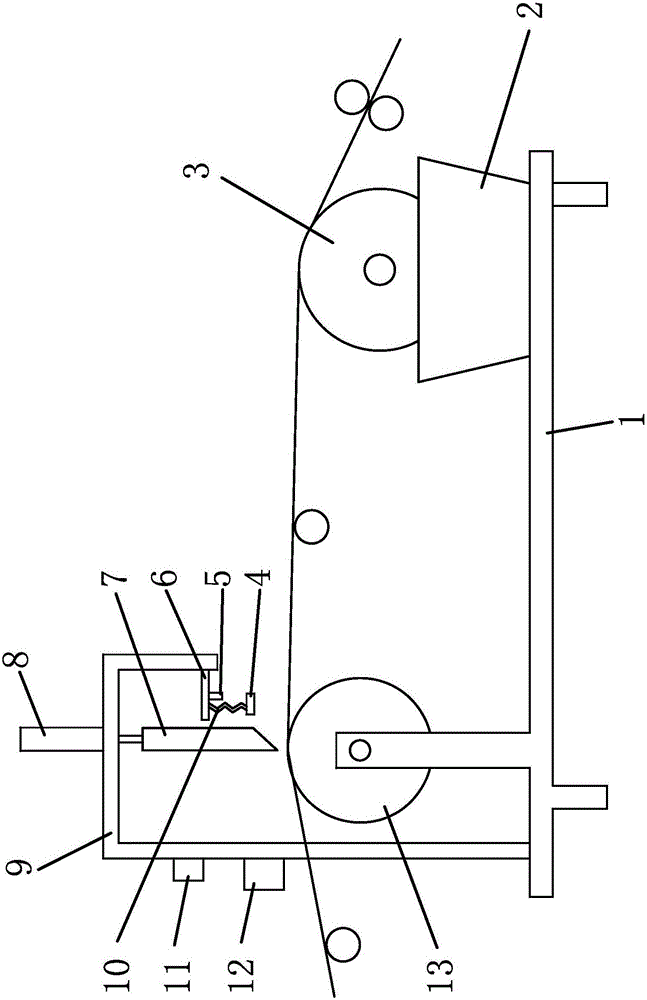

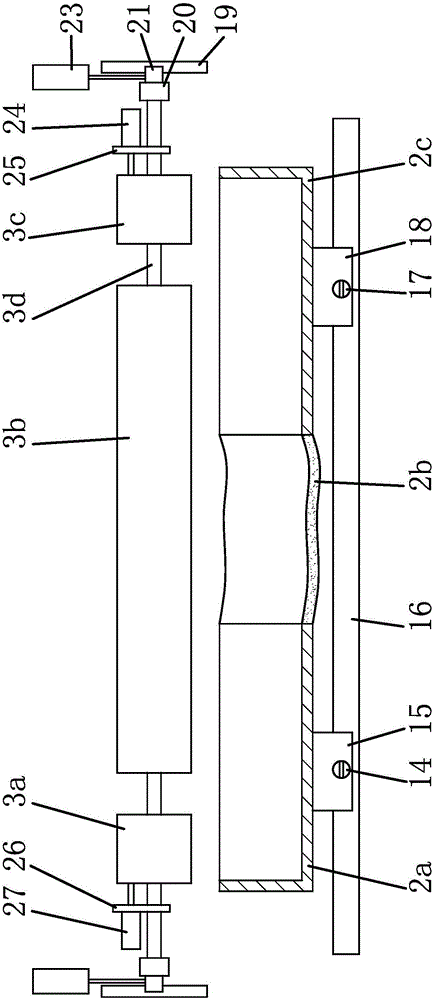

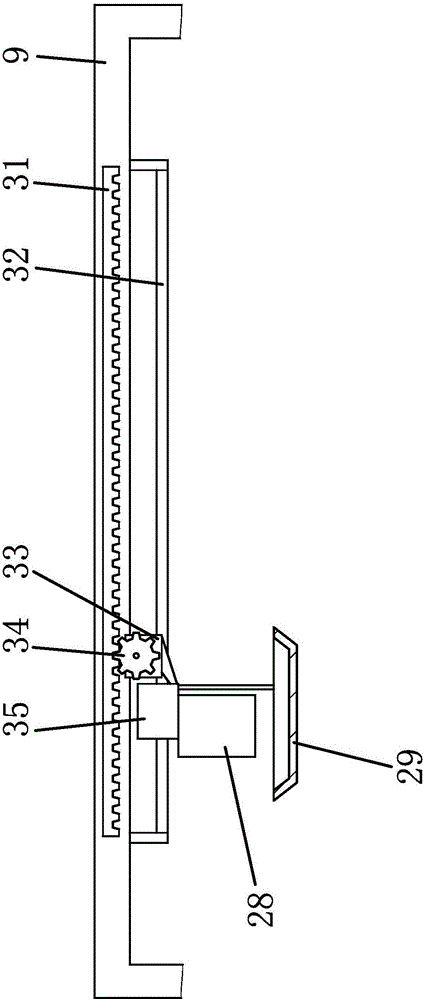

[0047] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0048] The ground cloth for military use includes a base cloth layer, and the upper and lower sides of the base cloth layer are provided with a PVC coating, and the PVC coating includes the following components by weight: 68-84 parts of PVC paste resin, 30-40 parts of plasticizer DINP, 6-10 parts of calcium carbonate, 2-8 parts of chlorinated paraffin, 1-6 parts of stabilizer, 12-18 parts of flame retardant, 4-10 parts of adhesive and 0.1-0.5 part of anti-UV agent; Among them, the flame retardant adopts the encapsulated antimony trioxide powder coated with chloroprene latex which is available on the market, the adhesive adopts the vinyl pyridine adhesive which is available on the market, and the anti-UV agent adopts the com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com