Production method of hard polychloroethylene section bar soft-hard coextrusion rubber strip

A rigid polyvinyl chloride, soft and hard co-extrusion technology, applied in the field of rigid polyvinyl chloride profile sealing strips, can solve the problem of large fluctuations in the hardness of adhesive properties, tensile properties and low-temperature toughness materials, and the content is not disclosed , Large difference in the size change rate of the sealant strip, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

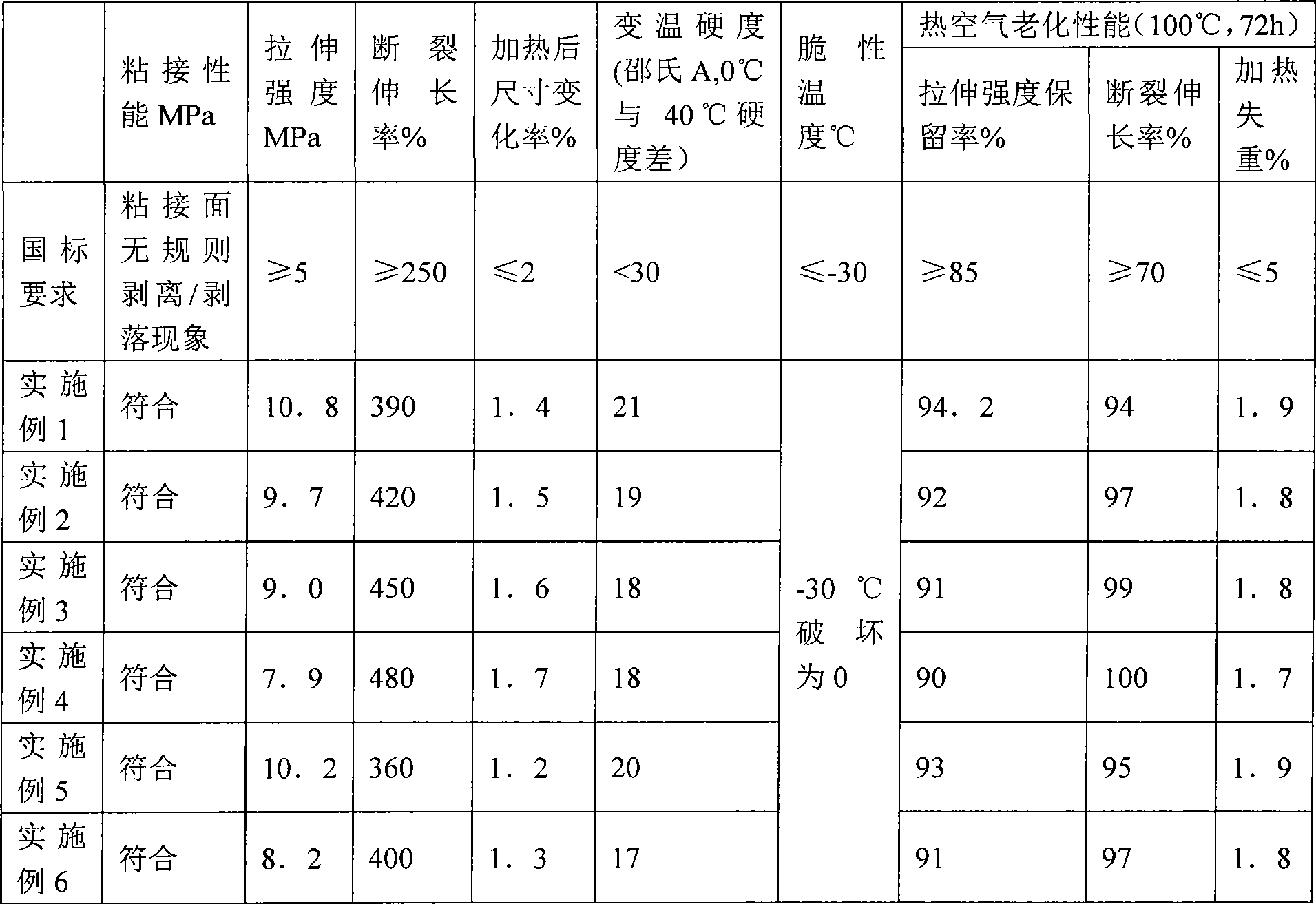

[0012] Table 1

[0013] Example pvc calcium carbonate Diisononyl phthalate Titanium dioxide Calcium zinc stabilizer 1 100 10 60 10 1 2 100 13 70 13 3 3 100 15 80 15 4.5 4 100 10 90 15 4 5 100 13 60 13 2 6 100 15 85 15 3

[0014] Referring to Table 1, various materials were prepared according to different weights to obtain Examples 1-6 with different proportions. This example was processed according to the following steps respectively.

[0015] 1. In the hot mixing pot of the hot mixer, rotate PVC, diisononyl phthalate, and calcium zinc stabilizer at 2000-2200 rpm to 110°C at high speed, then add calcium carbonate and titanium dioxide, and mix The material temperature is 125°C, and the material is discharged until it is cold mixed.

[0016] 2. On the cold mixer, the cooling water is lower than 14°C, and the premix is obtained by stirring at a low speed of 400-450 rpm.

[0017] 3. The premix is g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com