Pressure-resistant and abrasion-resistant wire PVC (Poly Vinyl Chloride) material

A PVC and pressure-resistant technology, applied in the field of polymer materials, can solve the problems of insufficient toughness and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

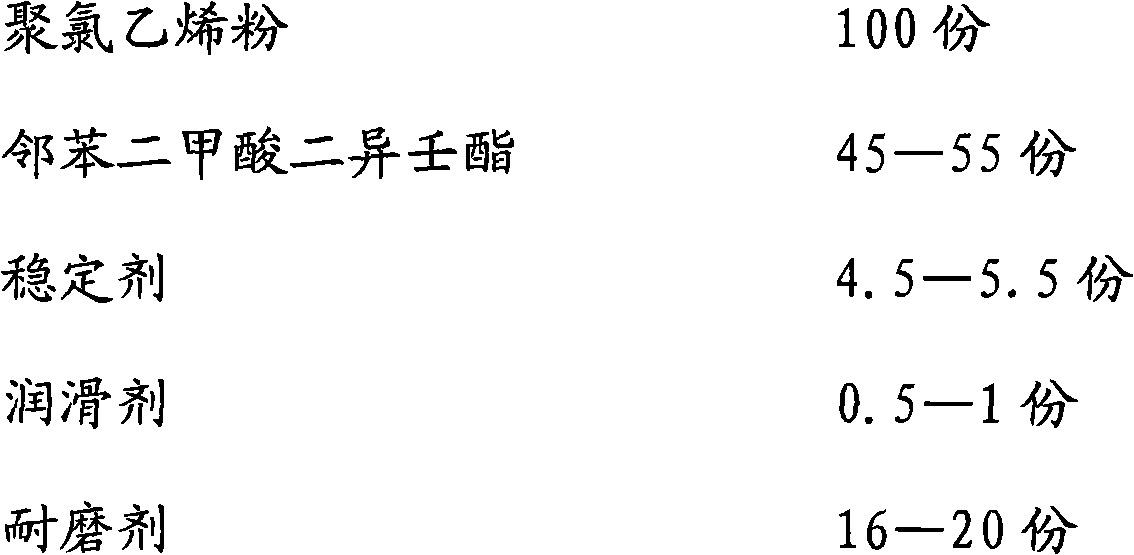

Embodiment 1

[0013]

[0014]

[0015] The stabilizer is calcium zinc stabilizer 301 for PVC wire and cable materials produced by Xinda Technology Co., Ltd., Heyuan City, Guangdong Province; the wear-resistant agent is wear-resistant agent T-850 produced by Dongguan Hongfu Chemical Co., Ltd., Guangdong Province; The lubricant is a mixture of 1 part of glycerol monostearate and 9 parts of polyethylene wax; the flame retardant is ammonium polyphosphate produced by Xinyuan Phosphating Co., Ltd., Zunyi County, Guizhou.

[0016] The pressure-resistant and wear-resistant wire made of this formula can reach the following indicators after testing:

[0017] 1. The number of wear resistance reaches 6000 times; 2. The pressure resistance performance reaches 200 pounds for 7.6 hours; 3. The pressure resistance of 500 pounds for 5 seconds does not break.

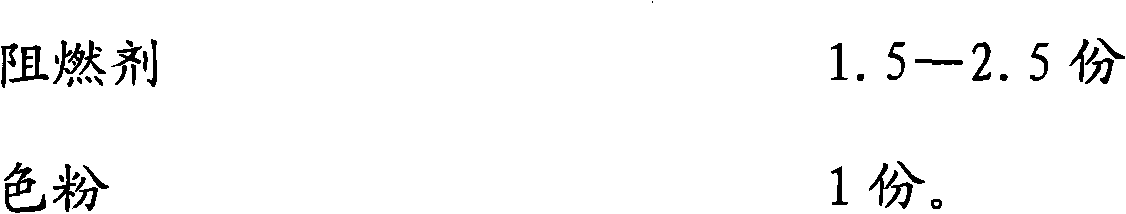

Embodiment 2

[0019]

[0020] The stabilizer is calcium zinc stabilizer 301 for PVC wire and cable materials produced by Xinda Technology Co., Ltd., Heyuan City, Guangdong Province; the wear-resistant agent is wear-resistant agent T-850 produced by Dongguan Hongfu Chemical Co., Ltd., Guangdong Province; The lubricant is polyethylene wax; the flame retardant is ammonium polyphosphate produced by Xinyuan Phosphating Co., Ltd., Zunyi County, Guizhou.

[0021] The pressure-resistant and wear-resistant wire made of this formula can reach the following indicators after testing:

[0022] 1. The number of wear resistance reaches 5400 times; 2. The pressure resistance performance reaches 200 pounds for 7.8 hours; 3. The pressure resistance of 500 pounds for 7 seconds does not break.

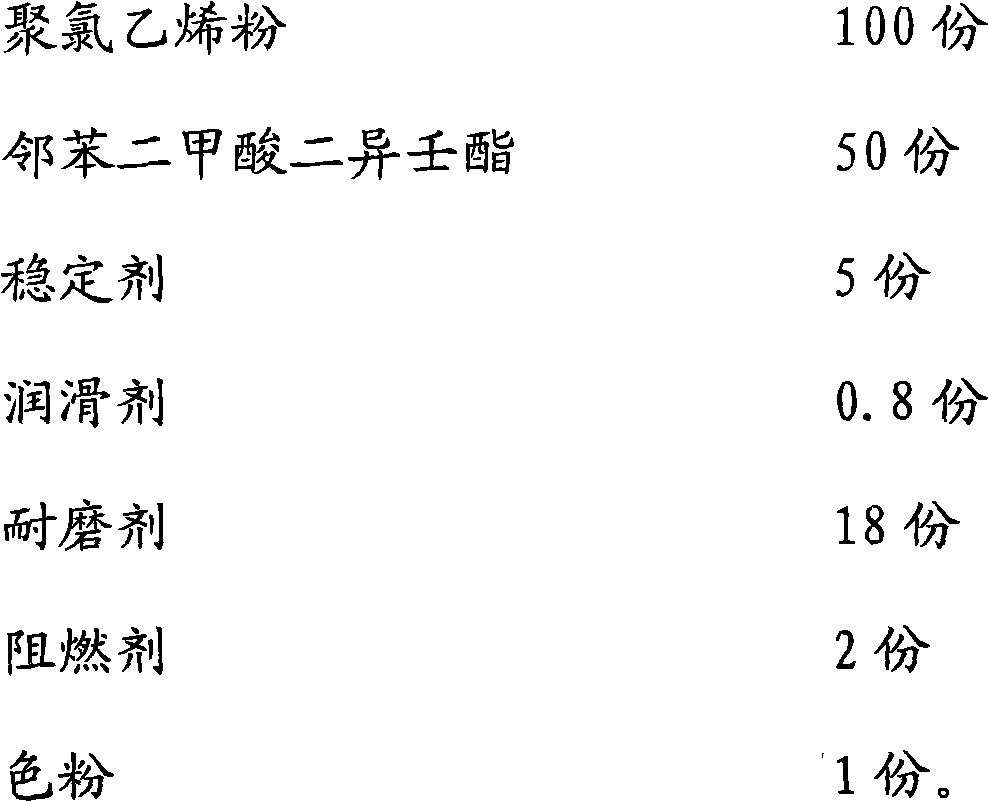

Embodiment 3

[0024]

[0025] The stabilizer is calcium zinc stabilizer 301 for PVC wire and cable materials produced by Xinda Technology Co., Ltd., Heyuan City, Guangdong Province; the wear-resistant agent is wear-resistant agent T-850 produced by Dongguan Hongfu Chemical Co., Ltd., Guangdong Province; The lubricant is polyethylene wax; the flame retardant is ammonium polyphosphate produced by Xinyuan Phosphating Co., Ltd., Zunyi County, Guizhou.

[0026] The pressure-resistant and wear-resistant wire made of this formula can reach the following indicators after testing:

[0027] 2. The number of wear resistance reaches 5500 times; 2. The pressure resistance performance reaches 200 pounds for 7.7 hours; 3. The pressure resistance of 500 pounds for 7 seconds does not break.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com