Aquaculture net cage antifouling paint and preparation method thereof

A technology for aquaculture and anti-fouling coatings, applied in the field of coatings, can solve the problems of poor adhesion of nylon thread flexible materials, cracking of anti-fouling coatings, high maintenance costs, etc., to achieve long-term anti-fouling performance, enhanced adhesion, and maintenance costs low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

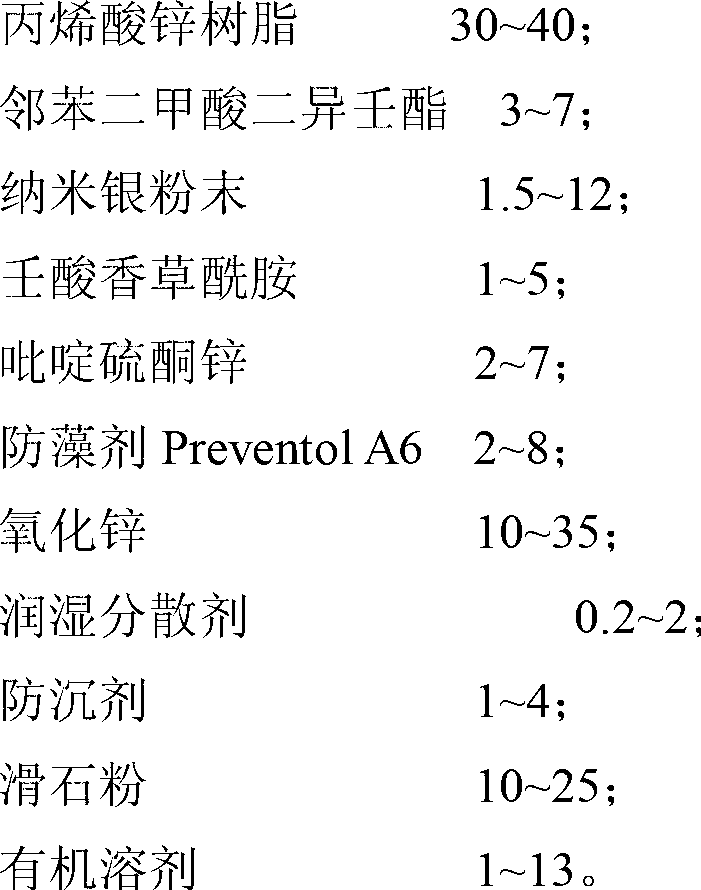

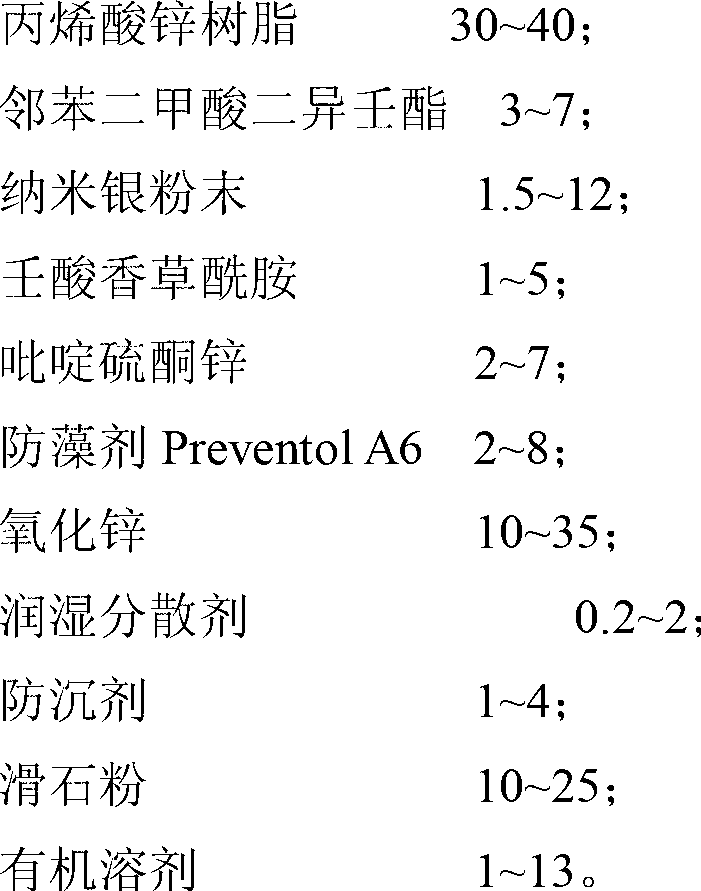

Method used

Image

Examples

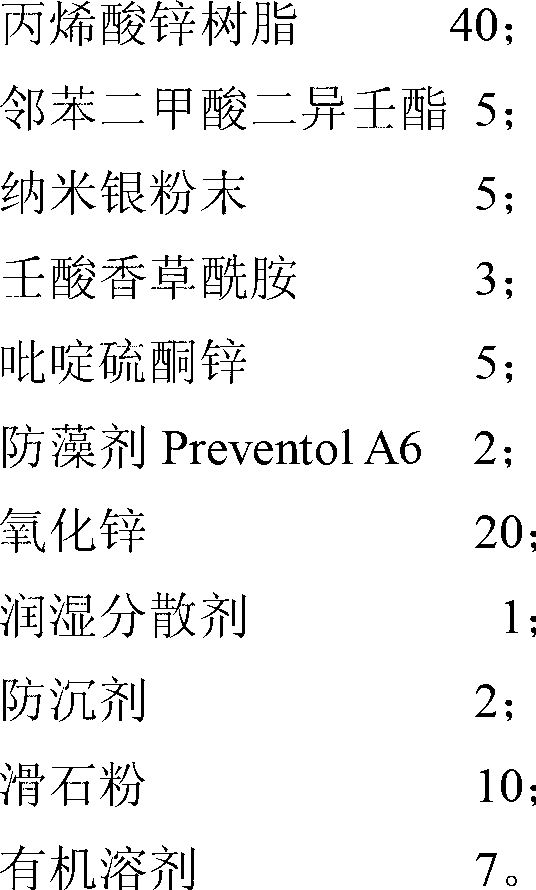

Embodiment 1

[0026] Embodiment 1, the antifouling coating for aquaculture cages in this embodiment includes the following components and their weight ratios: zinc acrylate resin 40; diisononyl phthalate 5; nano silver powder 5; vanillyl nonanoic acid 3; zinc pyrithione 5; anti-algae agent Preventol A6 2; zinc oxide 20; wetting and dispersing agent 1; anti-sedimentation agent 2; Among them, zinc acrylate resin is produced by Mitsubishi Rayon Co., Ltd., diisononyl phthalate is produced by West Asia Reagent Co., Ltd., nano-silver powder is produced by Sanbo Biochemical Technology (Shanghai) Co., Ltd., nonanoic acid vanillamide is produced by Hangzhou Xuanai Technology Co., Ltd., pyrithione zinc is produced by Wuxi Zhufeng Fine Chemical Co., Ltd., the anti-algae agent Preventol A6 is produced by Shanghai Lanxess, the wetting and dispersing agent is 2050 dispersant of BYK, and the anti-sedimentation agent is French. Cray Willy's Ultra anti-settling wax, the organic solvent is xylene.

[0027] ...

Embodiment 2

[0028] Embodiment 2, the antifouling paint of aquaculture net cage in the present embodiment comprises the following components and weight ratio thereof: zinc acrylate resin 35; Diisononyl phthalate 7; Nano silver powder 3; Nonanoic acid vanillyl amide 5; zinc pyrithione 7; anti-algae agent Preventol A6 4; zinc oxide 30; wetting and dispersing agent 0.4; anti-sedimentation agent 1.5; Among them, the wetting and dispersing agent is BYK's 2050 dispersing agent, the anti-sedimentation agent is 8300-02X produced by Shanghai Chencheng Chemical Co., Ltd., and the organic solvent is propylene glycol ether. Refer to Example 1 for other components and configuration methods.

Embodiment 3

[0029] Embodiment 3, the antifouling paint of aquaculture net cage in the present embodiment comprises the following components and weight proportion thereof: zinc acrylate resin 30; Diisononyl phthalate 5; Nano silver powder 9.5; Nonanoic acid vanillyl amide 1; zinc pyrithione 3; anti-algae agent Preventol A6 8; zinc oxide 10; wetting and dispersing agent 1.5; anti-sedimentation agent 4; talcum powder 18; organic solvent 1. Among them, the wetting and dispersing agent is BYK's 2050 dispersing agent, and the anti-sedimentation agent is 8300-02X produced by Shanghai Chencheng Chemical Co., Ltd. Refer to Example 1 for other components and configuration methods.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com