Method for preparing electrolyte ceramic membrane of lithium ion battery

A lithium-ion battery and electrolyte technology, which is applied in the preparation of lithium-ion battery electrolyte ceramic membranes, and in the field of preparation of lithium-ion battery electrolyte ceramic membranes by tape casting, can solve the problems of not being able to meet large-scale production applications, complex equipment, and high production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Method is the same as Comparative Example 1, according to Li 1.4 Al 0.4 Ge 0.8 Ti 0.8 (PO 4 ) 3 (LAG-TP) stoichiometric Li 2 CO 3 ,TiO 2 , Al(OH) 3 , GeO 2 with NH 4 h 2 PO 4 Mix evenly by ball milling, then heat treatment at 700°C for 2 hours for decomposition and synthesis, and grind after cooling to obtain powder.

[0018] Add the above-mentioned powder into an ethanol solvent, then add 2wt.% triethanolamine, 6wt.% PVB and 10wt.% plasticizer by weight of the powder, and continue ball milling for 4 hours to obtain a slurry for casting; flow The film obtained after delay has better strength and toughness. The dense electrolyte ceramics were obtained after sintering at 900℃ for 12h.

Embodiment 2

[0020] Method is the same as Comparative Example 1, according to Li 1.4 Al 0.4 Ti 1.6 (PO 4 ) 3 (LAG-TP) stoichiometric Li 2 CO 3 ,TiO 2 , Al(OH) 3 , GeO 2 with NH 4 h 2 PO 4 Mix evenly by ball milling, then heat treatment at 700°C for 2 hours for decomposition and synthesis, and grind after cooling to obtain powder.

[0021] Add the above powder into the azeotropic solution of propanol and trichlorethylene, then add 1wt% triethanolamine, 9wt% PVB and 10.5wt% plasticizer by weight of the powder, and continue ball milling for 4 hours to obtain cast The slurry used; the film obtained after casting has good strength and toughness. The dense electrolyte ceramics were obtained after sintering at 1000℃ for 12h.

Embodiment 3

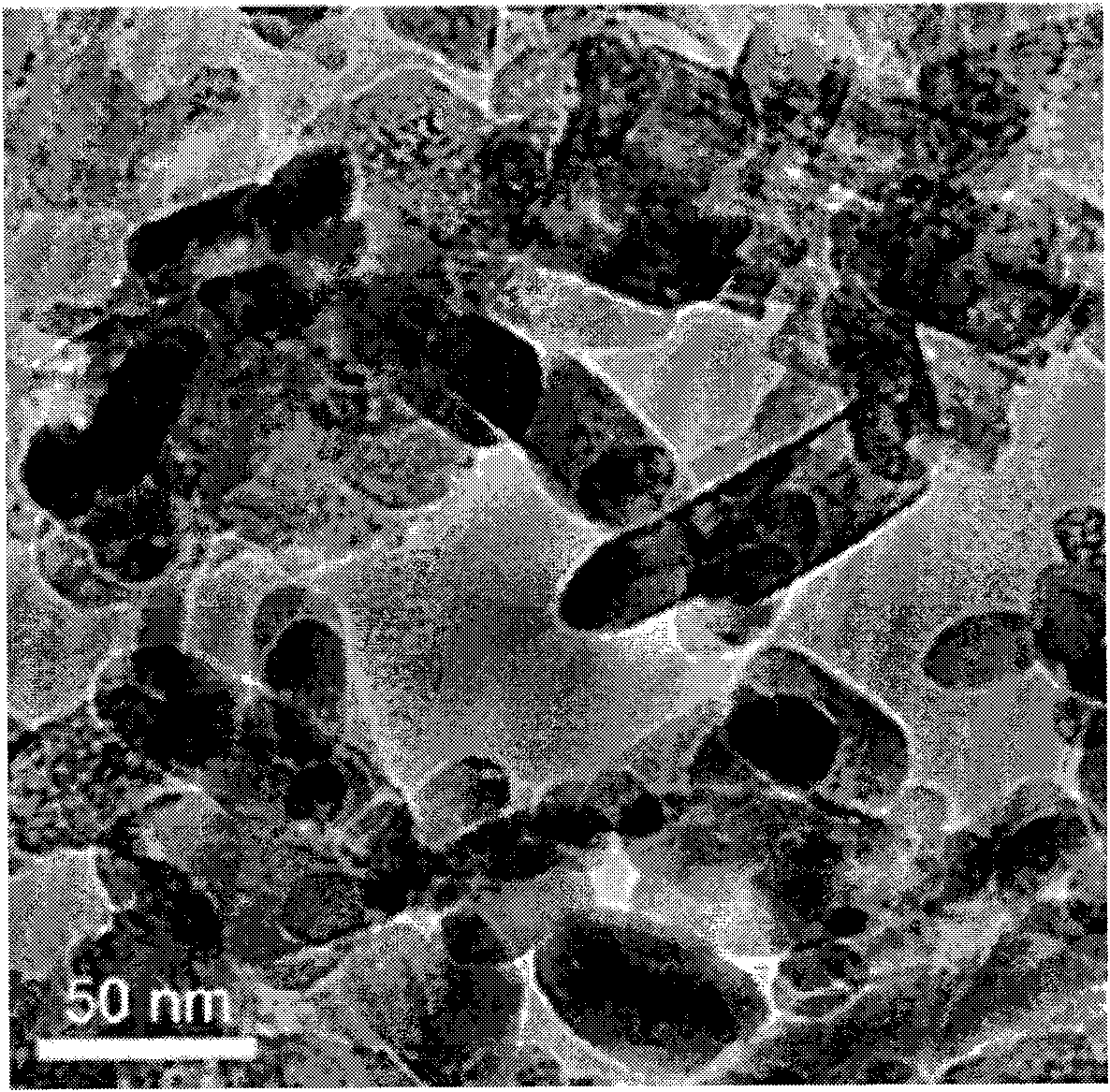

[0023] Analytical pure Li 2 CO 3 ,, Al(OH) 3 ,,TiO 2 with NH 4 h 2 PO 4 as raw material, according to Li 1.4 Al 0.4 Ge 0.96 Ti 0.64 (PO 4 ) 3 Stoichiometric ratio, fully divided and mixed, heat treated at 700°C for 4 hours to fully decompose easily decomposed products, then cooled and ground for later use. In a glove box with an argon atmosphere, a certain amount of precursor material is placed in a stainless steel tank, and a ball-milling medium stainless steel ball is added. The selected ball-to-material ratio is 15:1, the ball milling speed is 500 rpm, and ball milling is performed at room temperature to obtain an amorphous Powder. Powder TEM such as figure 2 shown.

[0024] Add the above-mentioned amorphous powder into the azeotropic solution of butanone and ethanol, then add 0.5wt.% phosphate ester, 4wt.% PVB and 8wt.% plasticizer by weight of the powder, and continue ball milling for 4 hours. A slurry for casting is obtained; the film obtained after casti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com