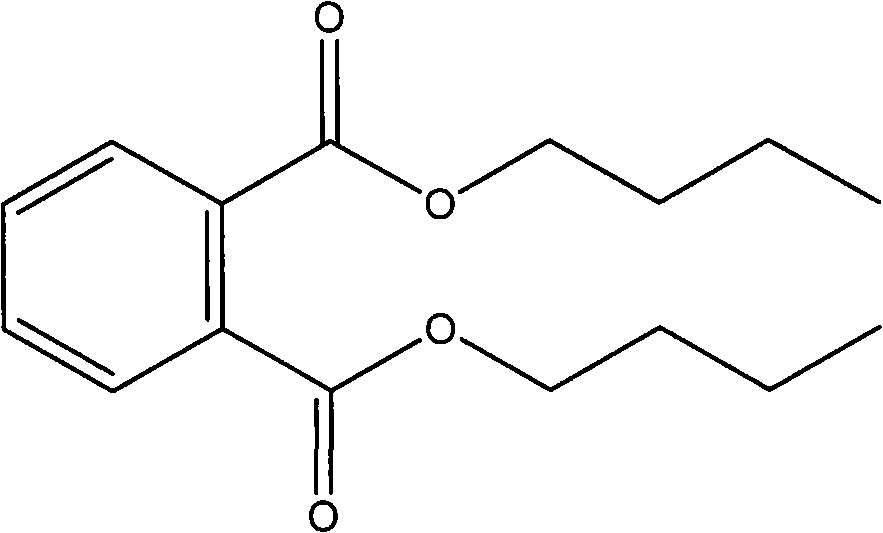

Method for preparing dibutyl phthalate

A technology of dibutyl phthalate and phthalic anhydride, which is applied in the production field of dibutyl phthalate, can solve problems such as difficult control of product quality, pollution of three wastes, side reactions, etc., and achieve short reaction time , Reduce waste water discharge, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The process steps of the present invention are: in a 250mL three-neck flask equipped with a stirrer, a thermometer, and a reflux condenser, add phthalic anhydride and n-butanol with a molar ratio of 1:2 to 1:3, and then add a catalyst for trioxidation Dialuminum 0.3-1.2%, heating and stirring with electric heating mantle, reflux reaction at 140-240°C for 3-4 hours; after the reaction, filter out the catalyst, distill n-butanol, and then distill with water steam to remove excess alcohol ; The crude product after dealcoholization is separated, filtered and vacuum distilled to obtain the product, and the refractive index of the product is measured.

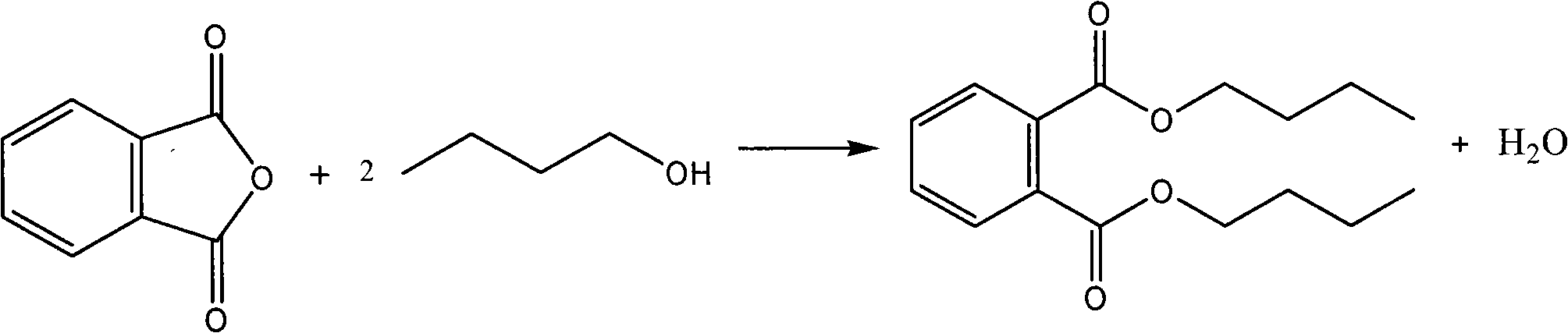

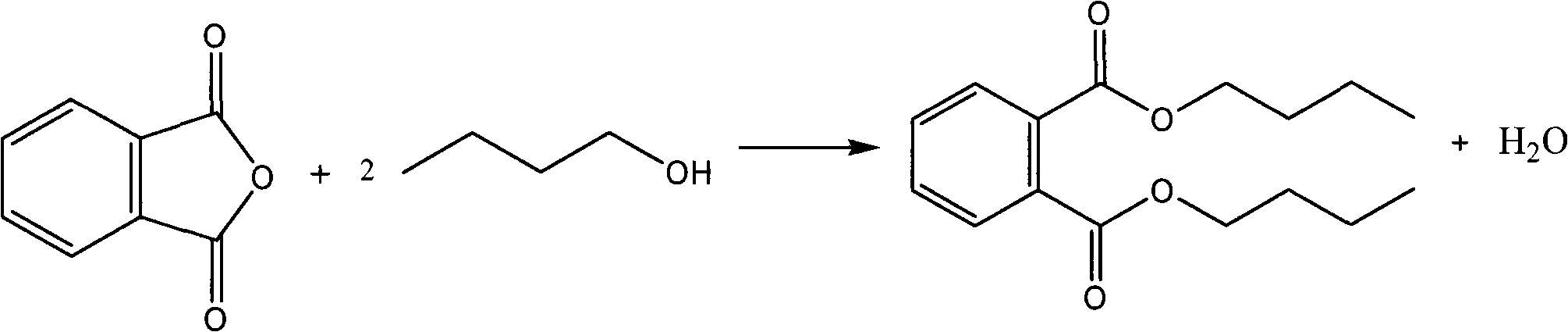

[0016] The reaction equation is:

[0017]

[0018] As a preferred solution, the process steps of the present invention are as follows: the molar ratio of phthalic anhydride and n-butanol is 1:3, the reaction temperature is 180-210°C, the reaction time is 3-4h, and the catalyst consumption is the total mass of the system 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com