Composite reagent kit for checking textile formaldehyde content

A compound reagent and formaldehyde content technology, which is applied in the direction of material analysis by observing the influence on chemical indicators, and analysis by making materials undergo chemical reactions, can solve the problem of easy deviation or misjudgment of formaldehyde content and inaccurate test results and other problems, to achieve the effect of simple and rapid operation, accurate and reliable results, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) Reagent

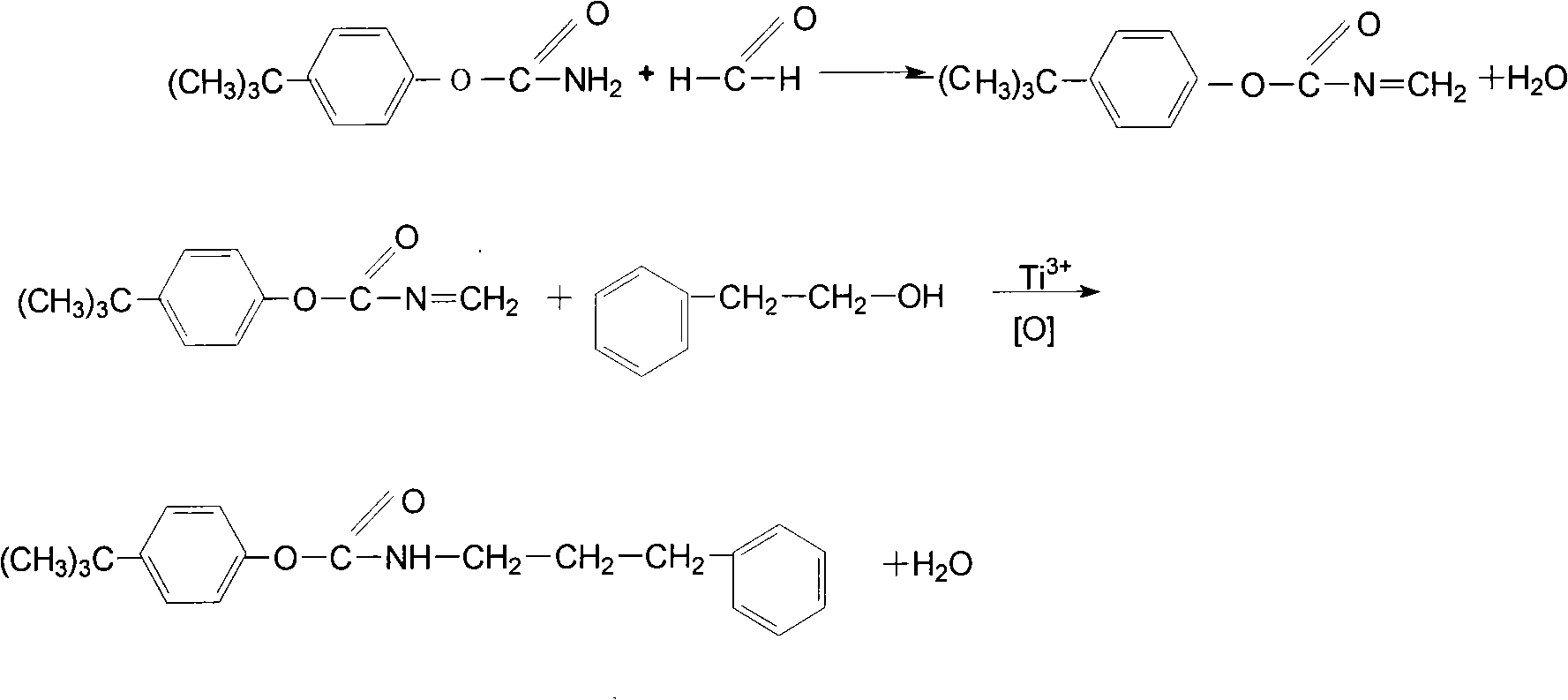

[0015] Composite reagent A: Mix evenly commercially available 0.1% butyl phenyl ester and commercially available 2% sodium sulfite in a weight ratio of 1:2.

[0016] Composite reagent B: Mix 0.9% phenylethyl alcohol solution and 0.2% sulfuric acid solution in a weight ratio of 1:1 evenly.

[0017] Equipped with nano titanium dioxide reagent.

[0018] (2) Detection

[0019] Put 100mL of distilled water and 0.15g of compound reagent into a conical flask to prepare compound reagent A solution; use a heater, beaker and thermometer to prepare 40°C distilled water; use an electronic balance to accurately weigh 1g of the sample to be tested and cut it into small pieces .

[0020] Take 100mL of distilled water at 40°C, 5mL of compound reagent A solution and the tested sample into the sampling cylinder, let the butyl phenyl ester in the compound reagent A react with the formaldehyde in the tested sample for 10 minutes; take 5mL of the solution from the sampling ...

Embodiment 2

[0022] (1) Reagent

[0023] Composite reagent A: Mix evenly commercially available 0.1% butyl phenyl ester and commercially available 2% sodium sulfite in a weight ratio of 1:3.

[0024] Composite reagent B: Mix 1.5% phenylethyl alcohol solution and 0.4% sulfuric acid solution in a weight ratio of 1:1 evenly.

[0025] Equipped with nano titanium dioxide reagent.

[0026] (2) detection

[0027] Put 100mL of distilled water and 0.15g of compound reagent into a conical flask to prepare compound reagent A solution; use a heater, beaker and thermometer to prepare 40°C distilled water; use an electronic balance to accurately weigh 1g of the sample to be tested and cut it into small pieces .

[0028] Take 100mL of distilled water at 40°C, 5mL of compound reagent A solution and the tested sample into the sampling cylinder, let the butyl phenyl ester in the compound reagent A react with the formaldehyde in the tested sample for 10 minutes; take 5mL of the solution from the sampling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com