Method for quickly detecting dibutyl phthalate in food

A fast technology of dibutyl phthalate, applied in measurement devices, instruments, fluorescence/phosphorescence, etc., can solve the problems of difficult to adapt to the rapid diagnosis of food industry, cumbersome sample processing, high monitoring costs, etc., to save detection time , the method is simple, the effect of short time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

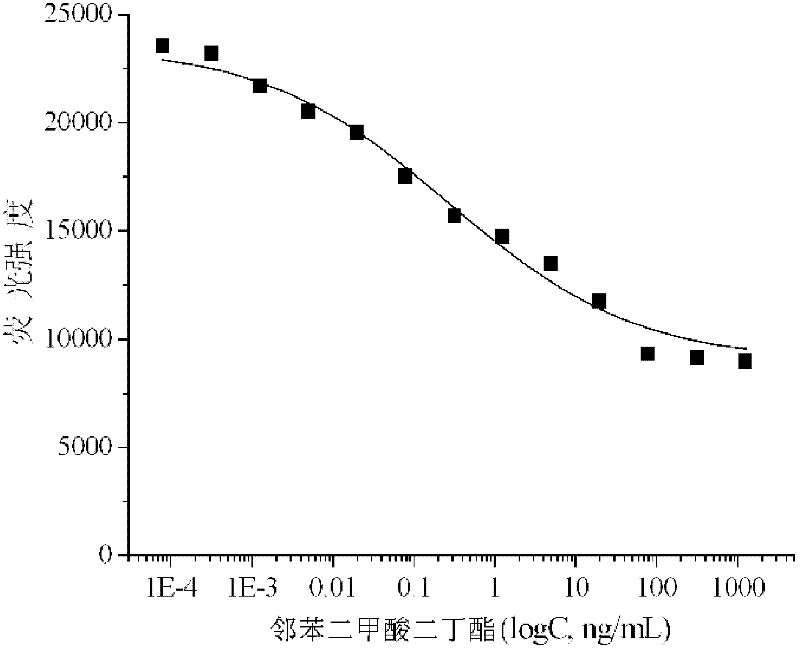

[0053] Establishment of the inhibition curve of dibutyl phthalate

[0054] (1) Coating steps:

[0055] The coating antigen DBAP-OVA at a concentration of 5μg / mL is coated with 96-well microtiter plate, 100μL per well, placed in the incubator and incubated at 37°C for 2h, then taken out of the incubator, shaken off the solution in the well, and then washed Wash with PBST and spin dry, wash 3-5min each time, wash 3 times in total.

[0056] (2) Closing steps:

[0057] Add 1% OVA solution, 150μL per well, to block the excess part that is not coated with antigen, to avoid non-specific adsorption of antibodies on the microtiter plate. After incubating at 37°C for 30 minutes, take it out of the incubator, shake off the solution in the well, and then wash as above.

[0058] (3) Competition steps:

[0059] Add 50μL of DBP standard solution and 50μL of fluorescent substance-labeled DBP antibody to each well to cause a competitive reaction. After incubating for 2.5 hours at 37°C, take it out of ...

Embodiment 2

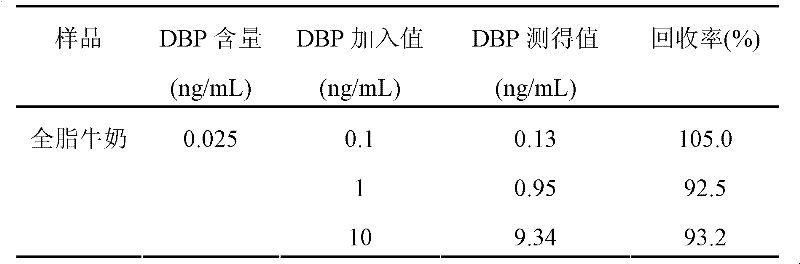

[0068] Detecting the content of dibutyl phthalate in whole milk and adding standard recovery experiment

[0069] The pretreatment steps of whole milk: Weigh 2.0 g of whole milk solid powder (purchased from Wuhu supermarket), dissolve it in 10 mL of hot (70-90°C) distilled water, and wait for it to cool. Add 2 mL of absolute ethanol to the above 10 mL solution, shake for 5 min, and then centrifuge at 10,000 rpm at low temperature (0-4° C.) for 10 min. After centrifugation, take out the test tube, remove the upper fat layer, transfer the middle solution layer to a clean glass container, and adjust the pH of the solution to 7.0 with 1mol / L NaOH or 1mol / L HCl. Store at low temperature (0-4℃) )under.

[0070] 1. Detect the content of dibutyl phthalate in whole milk

[0071] except

[0072] (3) Competition steps:

[0073] Add 50μL of treated whole milk solution and 50μL of fluorescent substance-labeled DBP antibody solution to each well to cause a competitive reaction. After incubating fo...

Embodiment 3

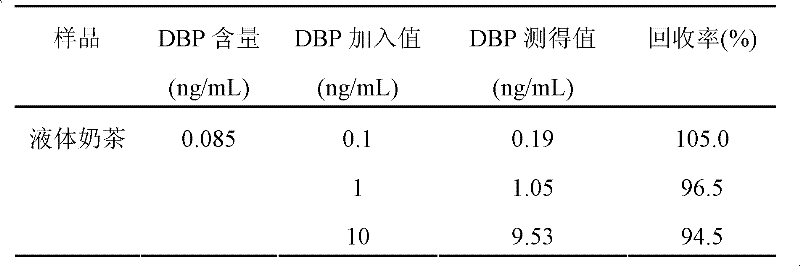

[0081] Example 3: Detecting the content of dibutyl phthalate in liquid milk tea and adding standard recovery experiment

[0082] Pretreatment steps of liquid milk tea:

[0083] Add 2 mL of absolute ethanol to 10 mL of purchased liquid milk tea (purchased in a Wuhu supermarket) solution, shake for 5 min, and then centrifuge at 10,000 rpm at low temperature (0-4° C.) for 10 min. After centrifugation, take out the test tube, remove the upper fat layer, transfer the middle solution layer to a clean glass container, and adjust the pH of the solution to 7.0 with 1mol / L NaOH or 1mol / L HCl. Store at low temperature (0-4℃) )under.

[0084] 1. Detect the content of dibutyl phthalate in milk tea

[0085] (1) Coating steps:

[0086] The coating antigen DBAP-OVA at a concentration of 5μg / mL is coated with 96-well microtiter plate, 100μL per well, placed in the incubator and incubated at 37°C for 2h, then taken out of the incubator, shaken off the solution in the well, and then washed Wash with PB...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com