Method for preparing samarium-doped titanium dioxide thin film

A technology of titanium dioxide and thin films, which is applied in the field of preparation of samarium-doped titanium dioxide thin films, can solve the problems of no self-cleaning effect and limited application range, etc., and achieve good film-forming properties, easy-to-obtain raw materials, and low reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

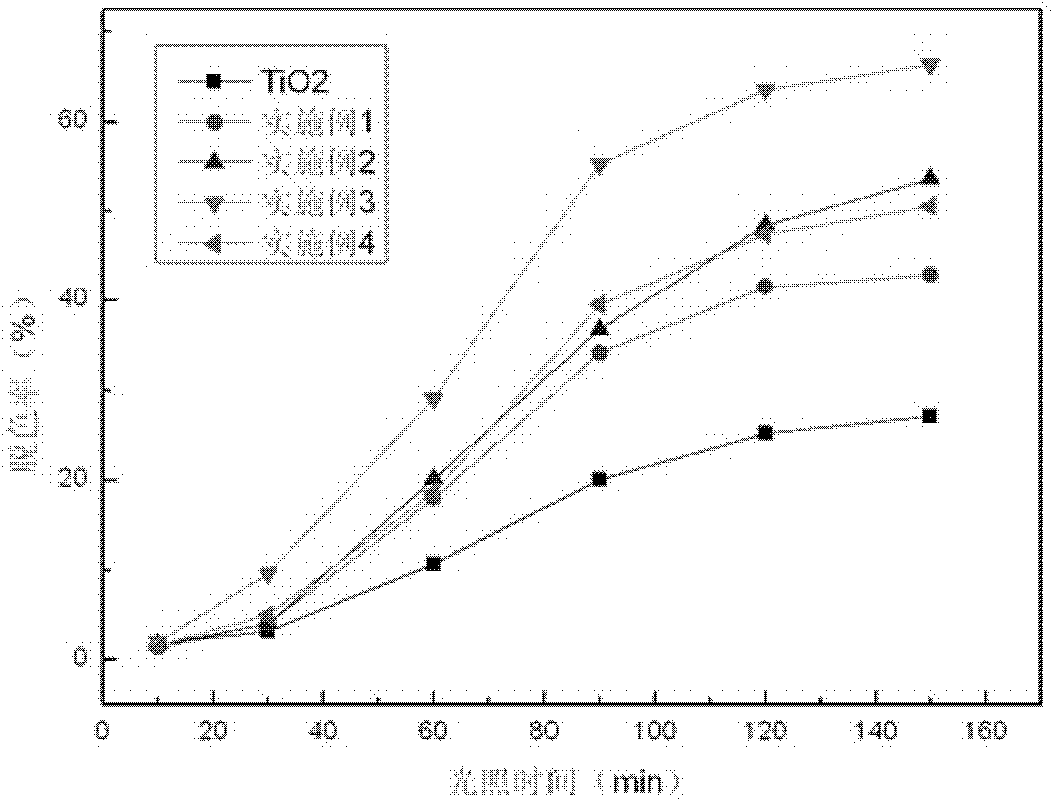

Examples

Embodiment 1

[0013] Embodiment 1: 1) will analytically pure butyl phthalate (C 16 h 36 o 4 Ti) and analytically pure absolute ethanol (C 2 h 5 OH) in a volume ratio of 1:0.5 to make a mixed solution, add analytically pure diethanolamine (C 4 h 11 NO 2 ) make the volume content of diethanolamine reach 3%, and make transparent solution A;

[0014] 2) deionized water, analytically pure acetylacetone (C 5 h 8 o 2 ) and analytically pure absolute ethanol are mixed uniformly according to the volume ratio of 1:0.5:10 to obtain a transparent solution B;

[0015] 3) According to the volume ratio of solution A and solution B being 2.5:1, slowly add solution B into solution A and keep stirring, adjust with analytically pure hydrochloric acid to make the pH value of the mixed solution reach 2.0, and form a uniform sol after magnetic stirring for 5 hours; The sol was aged at room temperature for 10 hours to obtain the gel C required for coating;

[0016] 4) Put the substrate to be coated int...

Embodiment 2

[0019] Embodiment 2: 1) will analytically pure butyl phthalate (C 16 h 36 o 4 Ti) and analytically pure absolute ethanol (C 2 h 5 OH) in a volume ratio of 1:1 to make a mixed solution, add analytically pure diethanolamine (C 4 h 11 NO 2 ) make the volume content of diethanolamine reach 5%, and obtain transparent solution A;

[0020] 2) deionized water, analytically pure acetylacetone (C 5 h 8 o 2 ) and analytically pure dehydrated ethanol are mixed uniformly according to the volume ratio of 1:2:15 to obtain a transparent solution B;

[0021] 3) According to the volume ratio of solution A and solution B being 2.5:1, slowly add solution B into solution A and keep stirring, adjust with analytically pure hydrochloric acid to make the pH value of the mixed solution reach 5.0, and form a uniform sol after magnetic stirring for 1 hour; The sol was aged at room temperature for 32 hours to obtain the gel C required for coating;

[0022] 4) Put the substrate to be coated into...

Embodiment 3

[0025] Embodiment 3: 1) will analytically pure butyl phthalate (C 16 h 36 o 4 Ti) and analytically pure absolute ethanol (C 2 h 5 OH) was mixed uniformly at a volume ratio of 1:3 to make a mixed solution, and analytically pure diethanolamine (C 4 h 11 NO 2 ) make the volume content of diethanolamine reach 6%, and obtain transparent solution A;

[0026] 2) deionized water, analytically pure acetylacetone (C 5 h 8 o 2 ) and analytically pure dehydrated ethanol are mixed uniformly according to the volume ratio of 1:1:13 to obtain a transparent solution B;

[0027] 3) According to the volume ratio of solution A and solution B being 2.5:1, solution B was slowly added to solution A and stirred continuously, adjusted with analytically pure hydrochloric acid to make the pH value of the mixed solution reach 4.0, and a uniform sol was formed after magnetic stirring for 3 hours; The sol was aged at room temperature for 48 hours to obtain the gel C required for coating;

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com