Flame retardant polysulfide sealant and its preparation process

A polysulfide sealant and preparation process technology, applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as hidden safety hazards, high cost, flammability, etc., and achieve the effects of long service life, low cost and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

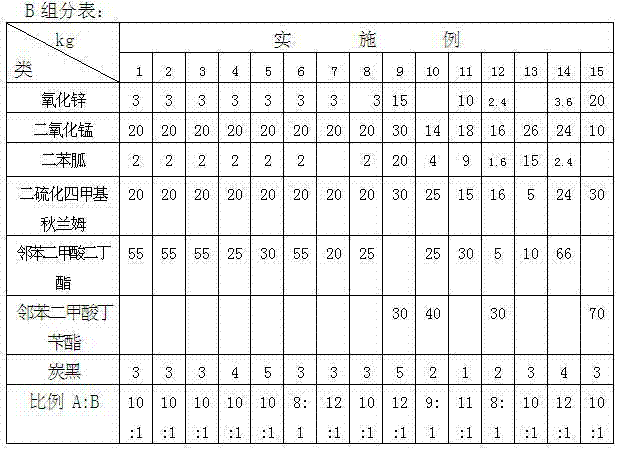

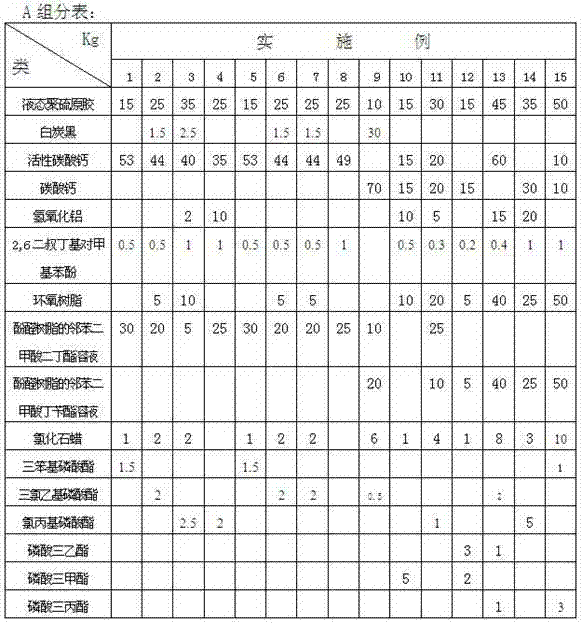

Examples

Embodiment 1

[0027] Component A: 15 parts of liquid polysulfide gum, 53 parts of activated calcium carbonate, 0.5 parts of antioxidant 2,6 di-tert-butyl-p-cresol, 1 part of chlorinated paraffin, 1.5 parts of triphenyl phosphate, phenolic resin 30 parts of dibutyl phthalate solution. Add the above materials into a vacuum-sealed mixer or grinder, and mix thoroughly for 30 minutes.

[0028] Component B: 55 parts of dibutyl phthalate, 3 parts of zinc oxide, 20 parts of manganese dioxide, 2 parts of vulcanization accelerator diphenylguanidine (D), vulcanization accelerator disulfide tetramethylthiuram (TDTM ) 20 parts, carbon black 3 parts. Add the above materials into a vacuum-sealed mixer or grinder, and mix thoroughly for 30 minutes.

[0029] Ratio A:B=10:1, mix well. When using, mix components A (white) and B (black) evenly in proportion and apply within 2 hours.

Embodiment 2

[0031] Component A: 25 parts of liquid polysulfide gum, 1.5 parts of white carbon black, 44 parts of activated calcium carbonate, 0.5 parts of antioxidant, 2 parts of chlorinated paraffin, 2 parts of trichloroethyl phosphate, phthalate of phenolic resin 20 parts of dibutyl formate solution, 5 parts of epoxy resin. Add the above materials into a vacuum-sealed mixer or grinder, and mix thoroughly for 30 minutes.

[0032] Component B: 55 parts of dibutyl phthalate, 3 parts of zinc oxide, 20 parts of manganese dioxide, 2 parts of vulcanization accelerator diphenylguanidine, 20 parts of vulcanization accelerator tetramethylthiuram disulfide, carbon black 3 copies. Add the above materials into a vacuum-sealed mixer or grinder, and mix thoroughly for 30 minutes.

[0033] Ratio A:B=10:1, mix well.

Embodiment 3

[0035] Component A: 35 parts of liquid polysulfide gum, 2.5 parts of white carbon black, 40 parts of activated calcium carbonate, 2 parts of aluminum hydroxide, 1 part of antioxidant, 2 parts of chlorinated paraffin, 2.5 parts of trichloropropyl phosphate, 5 parts of butyl benzyl phthalate solution of phenolic resin, 10 parts of epoxy resin. Add the above materials into a vacuum-sealed mixer or grinder, and mix thoroughly for 30 minutes.

[0036] Component B: 55 parts of dibutyl phthalate, 3 parts of zinc oxide, 20 parts of manganese dioxide, 2 parts of vulcanization accelerator diphenylguanidine, 20 parts of vulcanization accelerator tetramethylthiuram disulfide carbon, black 3 copies. Add the above materials into a vacuum-sealed mixer or grinder, and mix thoroughly for 30 minutes.

[0037] Ratio A:B=10:1, mix well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com