High-barrier, flame-retardant and anti-electrostatic epoxy-resin adhesive and preparation method thereof

A flame retardant, antistatic, epoxy resin technology, used in epoxy resin adhesives, adhesives, polymer adhesive additives, etc., can solve the problem that epoxy resin adhesives cannot meet the needs, and achieve excellent antistatic properties Good antistatic property, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

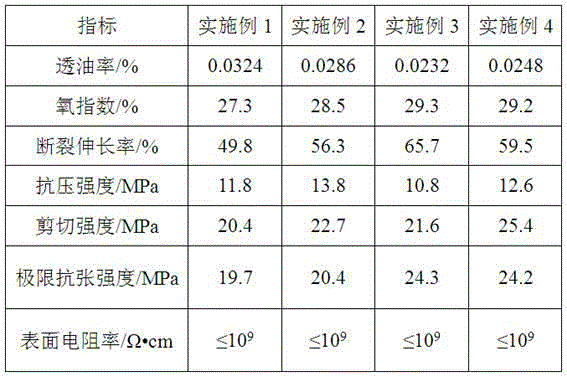

Examples

Embodiment 1

[0034] According to the following formula: by weight fraction

[0035] 100 parts epoxy resin

[0036] Ethylene / vinyl alcohol copolymer 4 parts

[0037] Polyamide resin 50 parts

[0038] Thermoplastic polyurethane 0 parts

[0039] N-Methylpyrrolidone 20 parts

[0040] Antistatic agent 0.5 parts

[0041] Modified nano-organic montmorillonite 2 parts

[0042] Modified nano silicon dioxide 1 part

[0043] Dibutyl phthalate 14 parts

[0044] Inorganic filler 3 parts

[0045] Dimethyl methyl phosphate 14 parts

[0046] Take each raw material according to the composition of the raw materials in Example 1, add 4 parts of ethylene / vinyl alcohol copolymer and 20 parts of N-methylpyrrolidone into reaction vessel 1, mix them uniformly in reaction vessel 1, and place them in a water bath at 70°C temperature, and the magnetic stirrer was stirred for 30 min at a rotational speed of 30 n / min to obtain a dissolved ethylene / vinyl alcohol copolymer. Take 100 parts of epoxy resin, 14 part...

Embodiment 2

[0048] According to the following formula: by weight fraction

[0049] 100 parts epoxy resin

[0050] Ethylene / vinyl alcohol copolymer 7 parts

[0051] 60 parts polyamide resin

[0052] 5 parts thermoplastic polyurethane

[0053] N-Methylpyrrolidone 25 parts

[0054] Antistatic agent 1.5 parts

[0055] Modified nano-organic montmorillonite 3 parts

[0056] Modified nano silica 2 parts

[0057] Dibutyl phthalate 17 parts

[0058] Inorganic filler 4 parts

[0059] Dimethyl methyl phosphate 17 parts

[0060] Take each raw material according to the raw material composition in Example 2, add 5 parts of thermoplastic polyurethane, 7 parts of ethylene / vinyl alcohol copolymer and 25 parts of N-methylpyrrolidone into reaction vessel 1, and mix in reaction vessel 1 homogeneously, in a water bath at a temperature of 70° C., and with a magnetic stirrer at a rotational speed of 30 n / min, stirring for 30 minutes to obtain a dissolved thermoplastic polyurethane and ethylene / vinyl al...

Embodiment 3

[0062] According to the following formula: by weight fraction

[0063] 100 parts epoxy resin

[0064] Ethylene / vinyl alcohol copolymer 10 parts

[0065] 70 parts of polyamide resin

[0066] 10 parts thermoplastic polyurethane

[0067] 30 parts of N-methylpyrrolidone

[0068] Antistatic agent 2.5 parts

[0069] Modified nano-organic montmorillonite 4 parts

[0070] Modified nano silicon dioxide 3 parts

[0071] 20 parts of dibutyl phthalate

[0072] Inorganic filler 5 parts

[0073] Dimethyl formate 20 parts

[0074] Take each raw material according to the composition of the raw materials in Example 3, add 10 parts of ethylene / vinyl alcohol copolymer and 30 parts of N-methylpyrrolidone into reaction vessel 1, mix them uniformly in reaction vessel 1, and place them in a water bath at 70°C temperature, and the magnetic stirrer was stirred for 30 min at a rotational speed of 30 n / min to obtain a dissolved ethylene / vinyl alcohol copolymer. Take 100 parts of epoxy resin, 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com