Net type foam film dust removal system for underground coal mine

A dust removal system and foam technology, applied in the fields of dust prevention, mining equipment, safety devices, etc., can solve the problems of inconvenient loading and unloading, large water consumption, difficult sewage treatment, etc., and achieve easy management, reduce water consumption, and increase contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

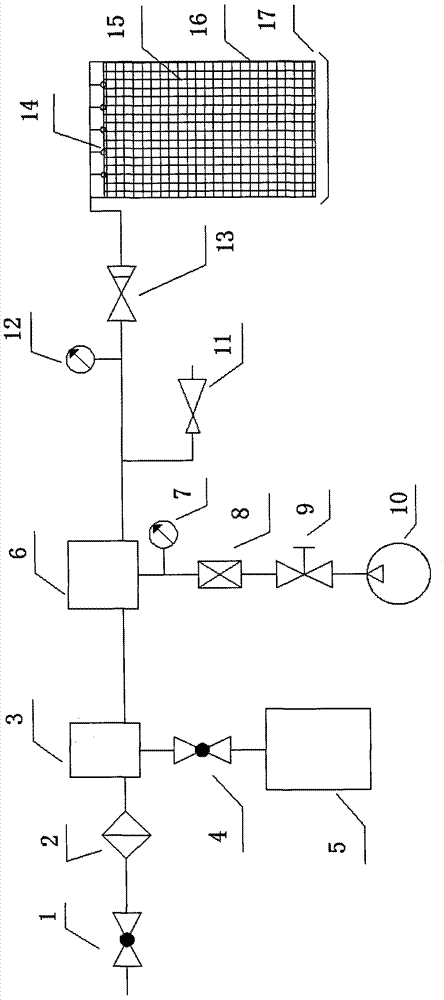

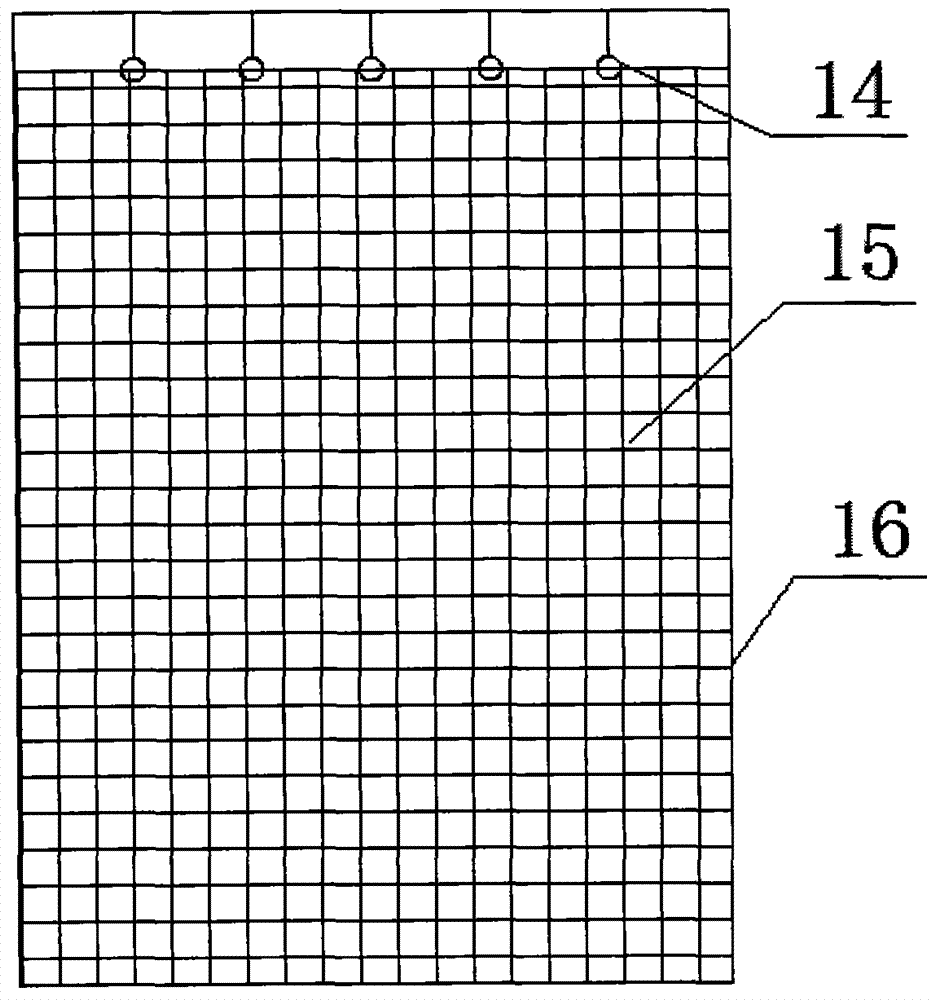

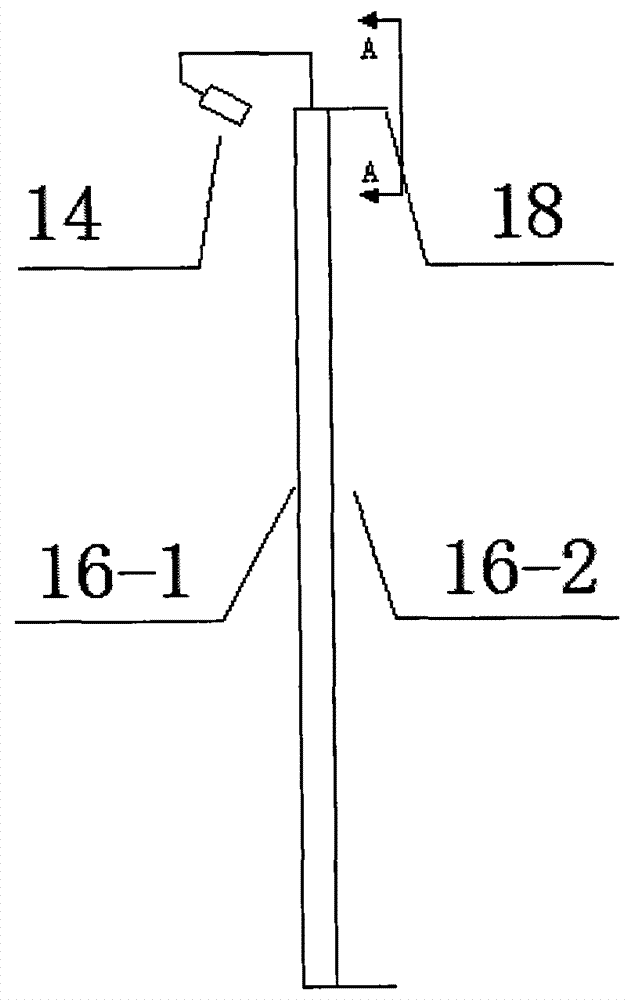

[0016] A specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0017] The net-type foam membrane dedusting system of the present invention is mainly composed of ball valves (1, 4), filter (2), fixed ratio adder (3), liquid storage tank (5), gas-liquid booster pump (6), driving gas Pressure gauge (7), air regulating valve (8), driving gas switch (9), air compressor (10), pressure reducing valve (11), high pressure gauge (12), check valve (13), foam nozzle (14), dust removal net (15), support (16,18) and gutter (17) form. When in use, inject a certain proportion of the foam stock solution into the liquid storage tank (5), connect the water source, open the ball valve (1) on the pipeline, start the gas-liquid booster pump (6) and the air compressor (10); The foaming liquid diluted by the adder (3) flows into the gas-liquid booster pump (6) to form a high-pressure fluid, and the high-pressure foaming liquid enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com