Glass powder for high temperature-resistant aluminum slurry and preparation method thereof

A technology for glass powder and high temperature resistance, which is applied in the field of glass powder for high temperature resistant aluminum paste and its preparation, can solve the problems of insufficient boiling resistance, reduced electrical properties, high temperature aluminum buds, etc., and achieves wide glass formation range and low surface tension. , The effect of not easy to crystallize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

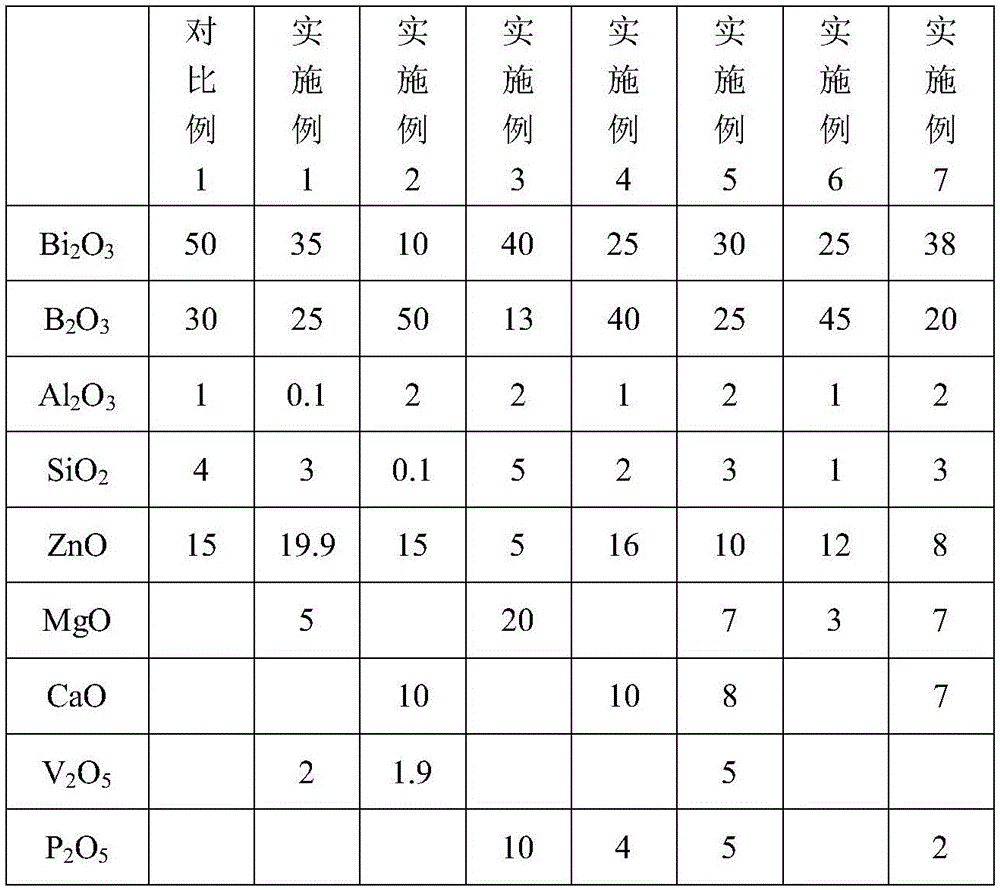

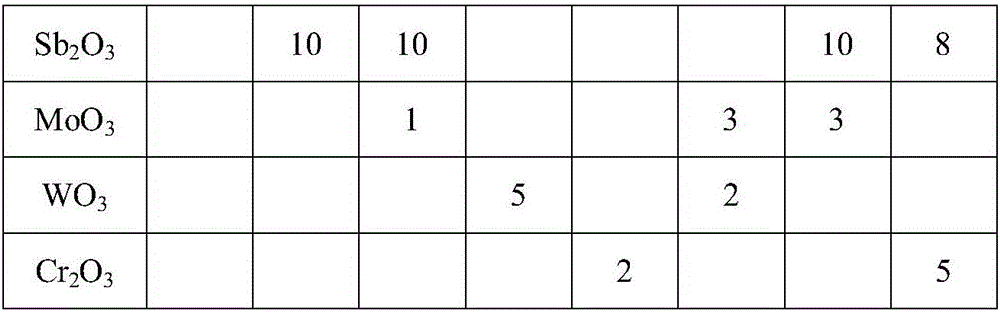

Embodiment 1

[0025] The glass powder for high-temperature-resistant aluminum paste provided in this embodiment is composed of the following raw materials in mass percentage:

[0026] Bi 2 o3 35%, B 2 o 3 25%, SiO 2 3%, Al 2 o 3 0.1%, ZnO 19.9%, MgO 5%, V 2 o 5 2%, Sb 2 o 3 10%.

[0027] where MgO comes from MgCO 3 , Al 2 o 3 from Al(OH) 3 .

[0028] The preparation method of glass powder for this high temperature resistant aluminum paste is as follows:

[0029] (1) According to the above-mentioned mass percentage, weigh various raw materials and mix them evenly in the mixer, put the mixed materials into the crucible for melting, adjust the melting temperature to 1000-1300°C, and heat-preserve and melt for 30-120 minutes;

[0030] (2) The glass slag quenched with deionized water is dried by ball milling with deionized water for 10 to 20 hours, and the glass slurry after ball milling is left to stand and separated to remove the upper layer of water, and then dried in an ...

Embodiment 2

[0032] The glass powder for high-temperature-resistant aluminum paste provided in this embodiment is composed of the following raw materials in mass percentage:

[0033] Bi 2 o 3 10%, B 2 o 3 50%, SiO 2 0.1, Al 2 o 3 2%, ZnO 15%, CaO 10%, V 2 o 5 1.9%, Sb 2 o 3 10%, MoO 3 1%.

[0034] where CaO comes from CaCO 3 , Al 2 o 3 from Al(OH) 3 .

[0035] The preparation method of the glass frit for the high temperature resistant aluminum paste is the same as in Example 1.

Embodiment 3

[0037] The glass powder for high-temperature-resistant aluminum paste provided in this embodiment is composed of the following raw materials in mass percentage:

[0038] Bi 2 o 3 40%, B 2 o 3 13%, SiO 2 5%, Al 2 o 3 2%, ZnO 5%, MgO 20%, P 2 o 5 10%, WO 3 5%.

[0039] The preparation method of the glass frit for the high temperature resistant aluminum paste is the same as in Example 1.

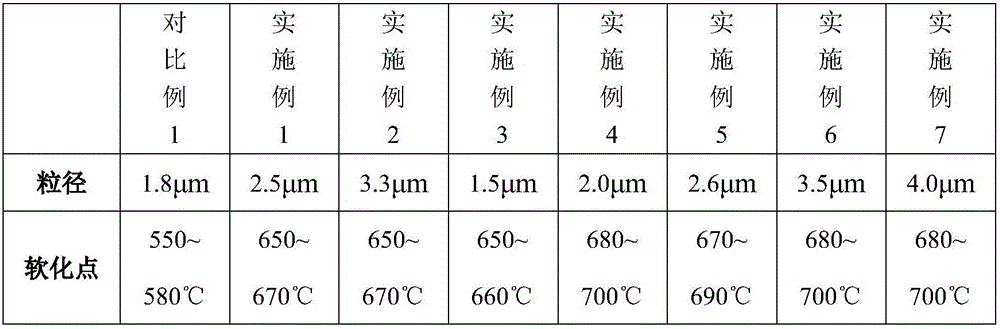

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com