Sewage station waste gas treatment device with composite biological method and waste gas treatment method of sewage station waste gas treatment device

A technology of waste gas treatment and biological method, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as high cost and secondary pollution, and achieve the effect of convenient operation, cost saving, and improved treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

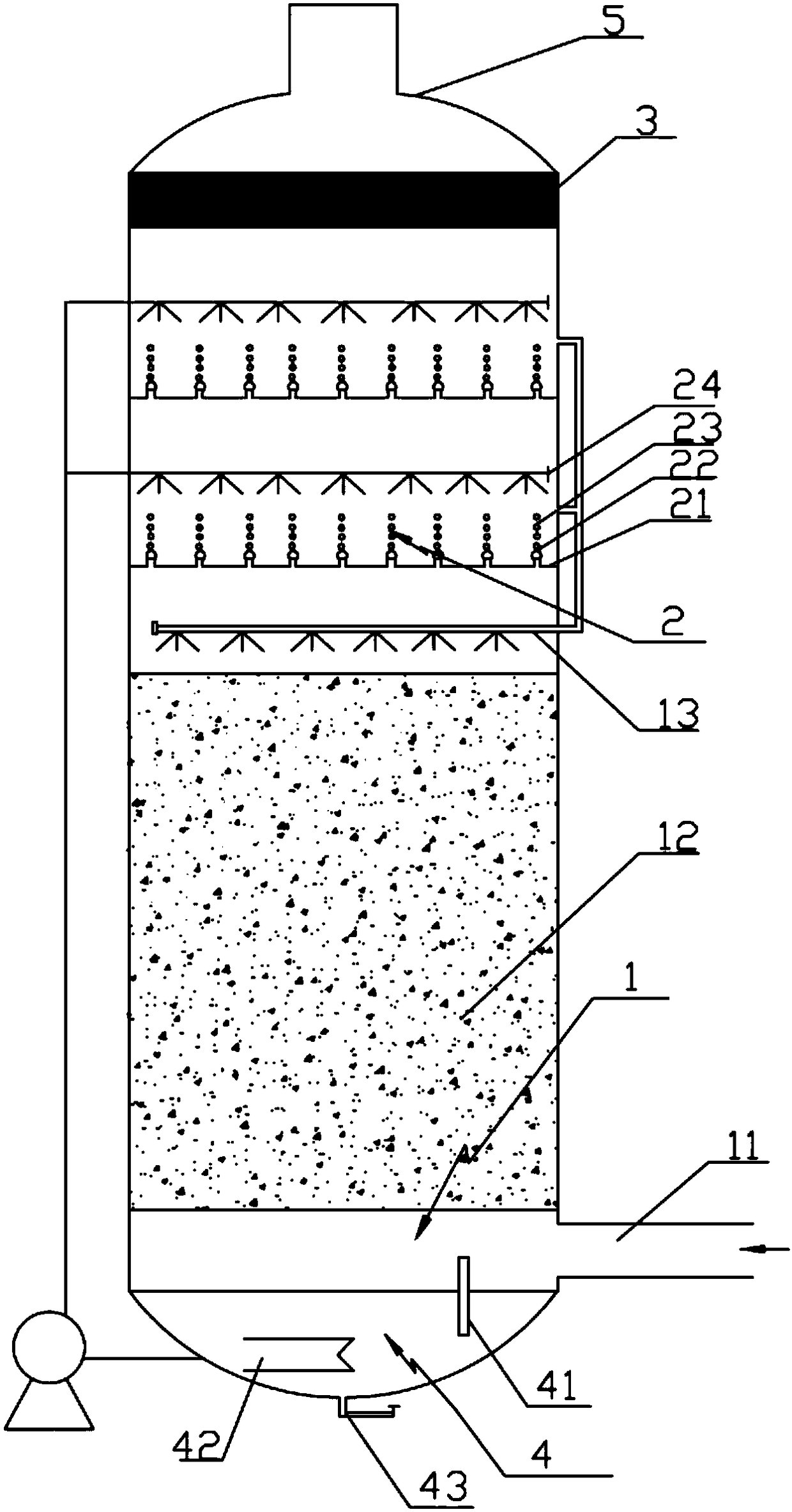

[0052] After the gas produced by the biochemical tank, collection tank and anaerobic tank of a sewage station is mixed (the gas volume is 5000Nm 3 / h, the concentration of non-methane total hydrocarbons is 58mg / Nm 3 (calculated as carbon), the concentration of hydrogen sulfide is 56mg / Nm 3 ), after being collected through the pipeline, enter the gas-liquid two-phase multi-stage biological purification treatment device. The designed cross-sectional flow velocity of waste gas in this project is 0.4m / s, the residence time is 5s, and the filler height is 2m. The filler is spongy petroleum coke particles, a by-product of the plant, and the indicators all meet the requirements. The biological absorption system is designed with two layers, and the spray density is 2m 3 / (m 2 · h), after the waste gas is treated by multi-stage biological purification, the microbial droplets and water droplets are removed by the demister and then discharged. The overall concentration of non-methane...

Embodiment 2

[0055] After the gas produced in the collection tank, biochemical tank and sludge concentration tank of a sewage station is mixed (the gas volume is 3000Nm 3 / h, the concentration of non-methane total hydrocarbons is 112mg / Nm 3 (calculated as carbon), part of the organic matter is sulfurized organic matter, and the concentration of hydrogen sulfide is 91mg / Nm 3 ), after being collected through the pipeline, enter the gas-liquid two-phase multi-stage biological purification treatment device. The designed waste gas cross-sectional velocity of this project is 0.3m / s, the residence time is 6s, and the filler height is 1.8m. The filler is spongy petroleum coke particles, a by-product of the plant, and the indicators all meet the requirements. The biological absorption system is designed with 3 layers, and the spray density is 3m 3 / (m 2 h). After the exhaust gas is treated by multi-stage biological purification, the microbial droplets and water droplets are removed by the demis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com