Dust suppressant, preparation method thereof, and dustproof method in opencast coal mining and coal transportation

A dust suppressant and dust-proof technology, applied in the field of dust suppressant, dust-proof and preparation in open-pit coal mining and coal transportation, can solve the problems of aggravating capital consumption, unable to effectively ensure dust-suppression efficiency, and increasing workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

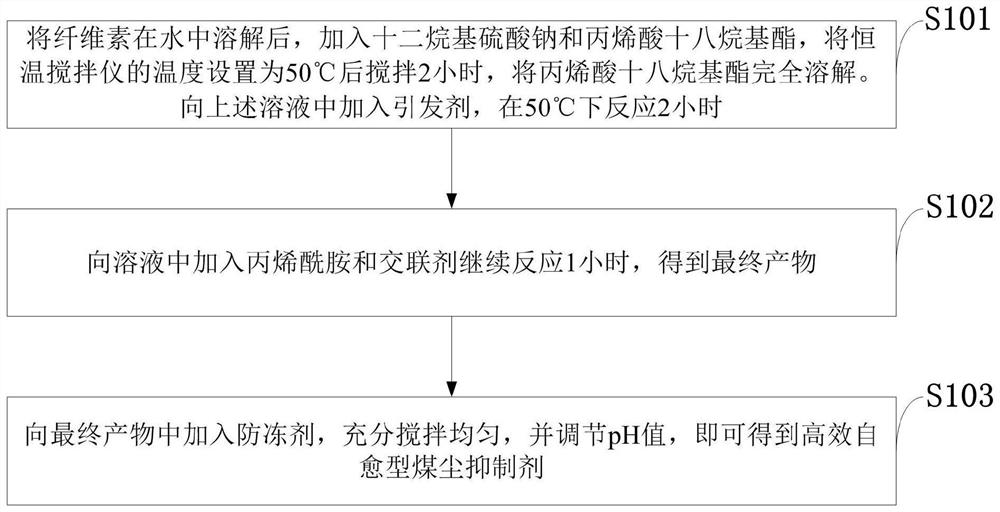

[0036] Such as figure 1 Shown, the preparation method of dust suppressant provided by the invention may further comprise the steps:

[0037] S101: After dissolving the cellulose in water, add sodium lauryl sulfate and stearyl acrylate, set the temperature of the constant temperature stirrer at 50°C and stir for 2 hours to completely dissolve the stearyl acrylate. Add an initiator to the above solution and react at 50°C for 2 hours;

[0038] S102: adding acrylamide and a crosslinking agent to the solution to continue the reaction for 1 hour to obtain a final product;

[0039] S103: Add antifreeze to the final product, stir well, and adjust the pH value to obtain a highly efficient self-healing coal dust inhibitor.

[0040] In an embodiment of the present invention, the mass ratio of inhibitor to water is 1:80.

[0041] In an embodiment of the present invention, the reaction process of step S101 is:

[0042]

[0043] In an embodiment of the present invention, the reaction...

Embodiment 1

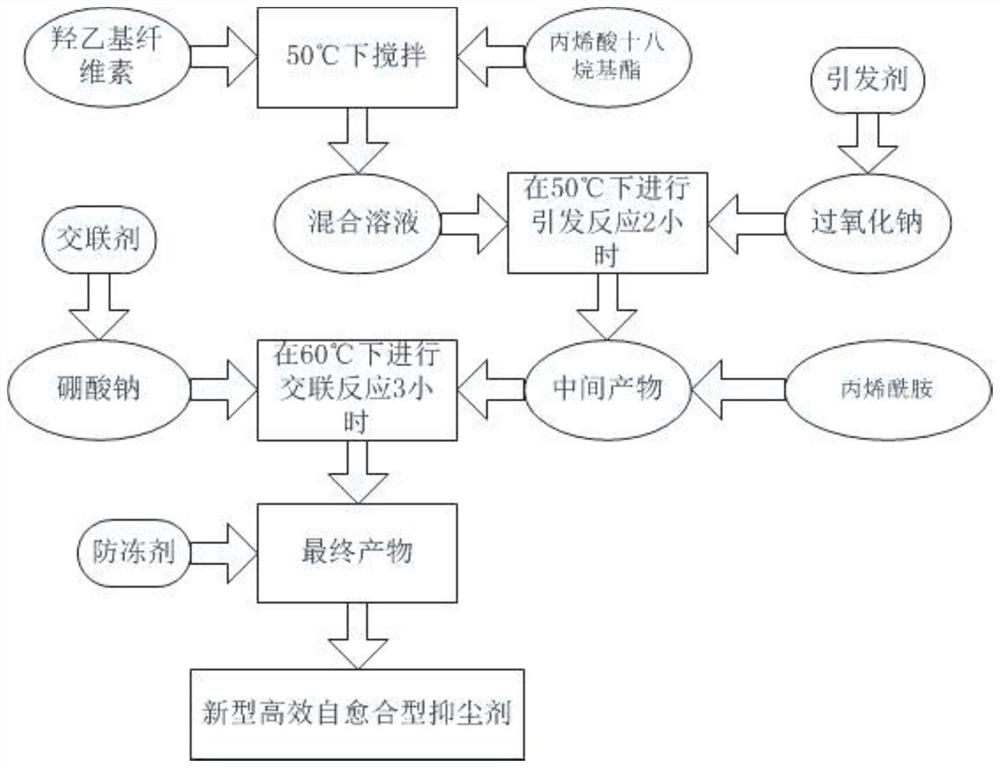

[0049] The embodiment of the present invention weighs 4g of hydroxyethyl cellulose and dissolves it in 200ml of water, extracts 4ml of stearyl acrylate and 2ml of sodium lauryl sulfate into the water with a rubber dropper, and waits until the stearyl acrylate is completely After dissolving and emulsifying, 0.5 g of sodium peroxide was added to the solution, and the reaction was stirred at a constant temperature of 50° C. for 2 hours. Add 2 g of acrylamide and 0.5 g of N-N sodium borate to the solution, keep stirring at 60° C. for 3 hours. After the reaction was completed, 0.3g of calcium chloride was added to the solution to adjust the pH and test related properties.

Embodiment 2

[0051] The embodiment of the present invention weighs 4g of hydroxyethyl cellulose and dissolves it in 200ml of water, extracts 6ml of stearyl acrylate and 2ml of sodium lauryl sulfate into the water with a rubber dropper, and waits until the stearyl acrylate is completely After dissolving and emulsifying, 0.5 g of sodium peroxide was added to the solution, and the reaction was stirred at a constant temperature of 50° C. for 2 hours. Add 2 g of acrylamide and 0.5 g of sodium borate to the solution, and keep stirring at 60° C. for 3 hours. After the reaction was completed, 0.3g of calcium chloride was added to the solution to adjust the pH and test related properties.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com