Industrial heavy oil dirt cleaning agent and preparation method thereof

A heavy oil stain cleaning agent, industrial technology, applied in the direction of detergent composition, detergent compounding agent, chemical equipment and methods, etc., can solve the problem of unsatisfactory semi-solid oil stain cleaning ability, and achieve improved compatibility and stability Non-toxic, easy to degrade, and long-term decontamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

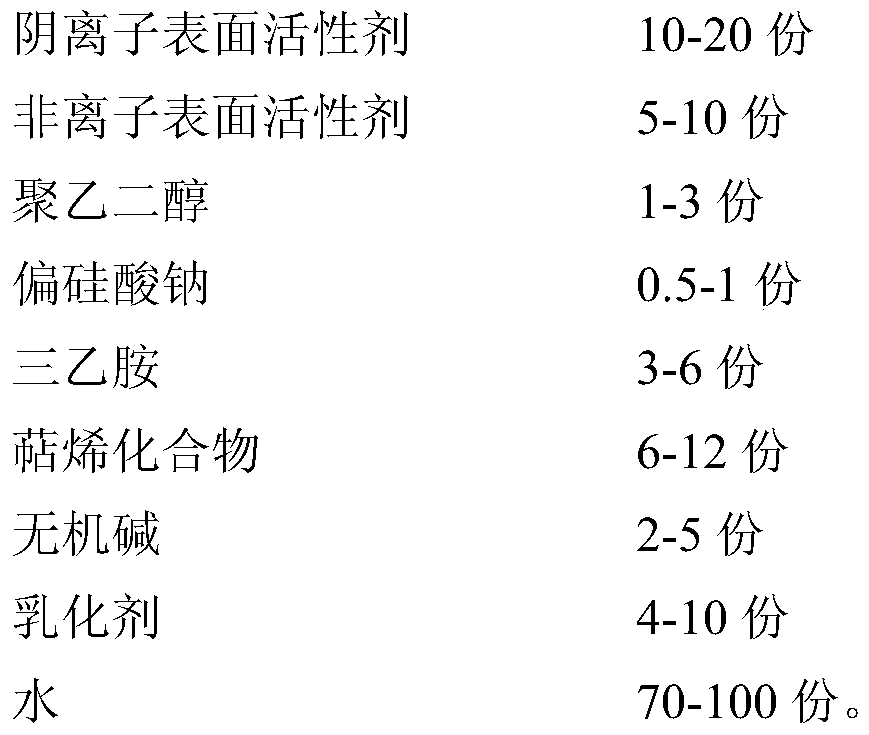

[0043] An industrial heavy oil dirt cleaning agent, comprising the following components in parts by mass:

[0044]

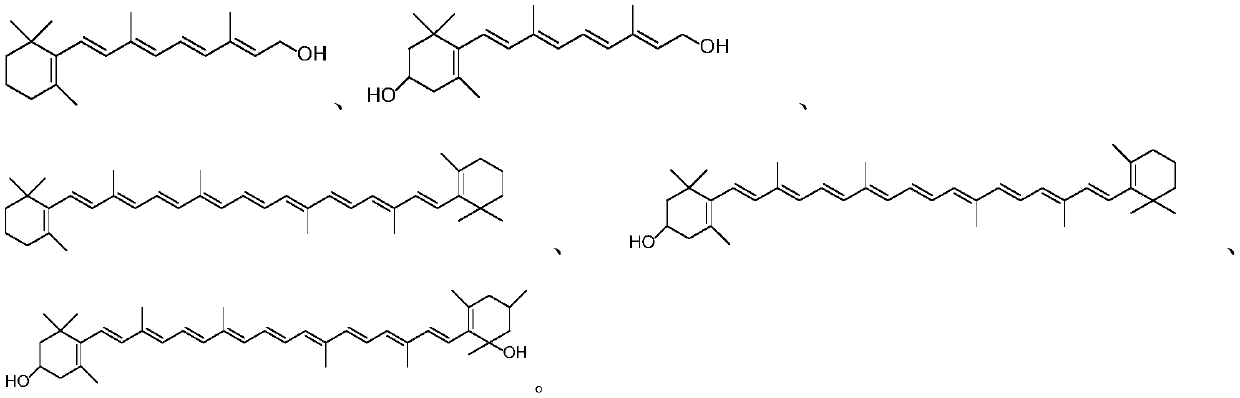

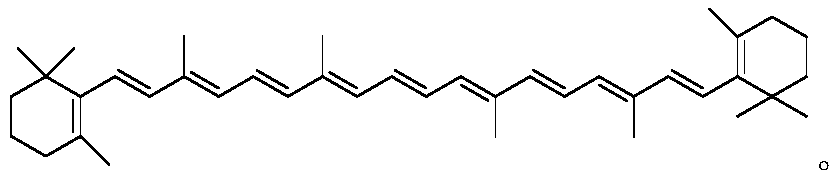

[0045] The terpene compound is selected from the following structures:

[0046]

[0047] The preparation method of above-mentioned industrial heavy oil dirt cleaning agent, comprises the following steps:

[0048] S1. 70 parts by mass of water are first added to the reactor, and then 10 parts by mass of anionic surfactant LAS and 5 parts by mass of nonionic surfactant fatty alcohol polyoxyethylene ether are added, Then the temperature was raised to 40°C, and stirred at a speed of 450rpm for 10min, so that the above-mentioned ingredients were dissolved in water;

[0049] S2. Adding 4 parts by mass of emulsifier Tween-20 to the above mixture to form a mixture;

[0050] S3. Then the above mixture was heated to 55° C., stirred at a rotating speed of 600 rpm, and 6 parts by mass of the terpene compound of the above structure were added in batches to the above mi...

Embodiment 2

[0056] An industrial heavy oil dirt cleaning agent, comprising the following components in parts by mass:

[0057]

[0058] The terpene compound is selected from the following structures:

[0059]

[0060] The preparation method of above-mentioned industrial heavy oil dirt cleaning agent, comprises the following steps:

[0061] S1. Add 100 parts by mass of water to the reactor first, then add 20 parts by mass of anionic surfactant AES and 10 parts by mass of nonionic surfactant polyoxyethylene amide, and then heat up To 50°C, stir at 650rpm for 30min to dissolve the above ingredients in water;

[0062] S2. Adding 10 parts by mass of emulsifier Tween-80 to the above mixture to form a mixture;

[0063] S3. Then the above mixture is heated to 65° C., stirred at a rotating speed of 800 rpm, and 12 parts by mass of the terpene compound of the above structure are added in batches to the above mixture, and the batch addition method is as follows:

[0064] (1) The time interv...

Embodiment 3

[0069] An industrial heavy oil dirt cleaning agent, comprising the following components in parts by mass:

[0070]

[0071]

[0072] The terpene compound is selected from the following structures:

[0073]

[0074] The preparation method of above-mentioned industrial heavy oil dirt cleaning agent, comprises the following steps:

[0075] S1. Add 80 parts by mass of water to the reactor first, then add 15 parts by mass of anionic surfactant AEC and 7 parts by mass of nonionic surfactant dodecyldiethanolamide , and then heated up to 45°C, and stirred at a speed of 550rpm for 20min, so that the above ingredients were dissolved in water;

[0076] S2. Adding 7 parts by mass of emulsifier Span-80 to the above mixture to form a mixture;

[0077] S3. Then the above mixture is heated to 60° C., stirred at a rotating speed of 700 rpm, and 10 parts by mass of the terpene compound of the above structure are added in batches to the above mixture, and the batch addition method is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com