Highway T-beam transverse diaphragm prestressed reinforcement structure and its strengthening method

A technology for strengthening structures and transverse prestressed tendons, which is applied in bridge reinforcement, bridges, bridge materials, etc., can solve the problems of small cross-section of beams, inability to drill holes and wear reinforcements, complex live load mechanism of highway bridges, etc., and achieve improvement Working status, reducing comprehensive cost and construction difficulty, enhancing the effect of lateral connection and undertaking prestressed support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific structure of the prestressed reinforcement structure of a highway T-beam diaphragm provided by the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

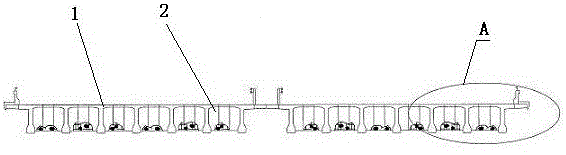

[0040] like figure 1 As shown, the T-beam of the highway before reinforcement includes a beam body 1 , and there are originally a plurality of transverse diaphragms 2 under the beam body 1 .

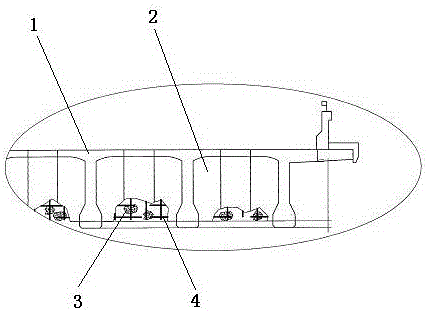

[0041] like figure 2 As shown, the T-beam of the road before reinforcement includes a beam body 1, and there are originally a plurality of diaphragms 2 under the beam body 1, and the diaphragm 2 has damaged concrete 3 and damaged steel bars 4.

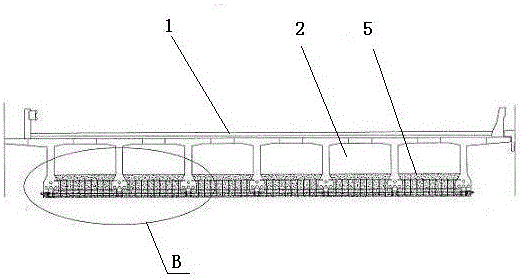

[0042] like image 3 As shown, a prestressed reinforcement structure of a highway T-beam diaphragm of the present invention includes a beam body 1 in the direction of the transverse bridge, a plurality of diaphragms 2 under the beam body 1, the lower part of the diaphragm 2 and the diaphragm 2 Concrete reinforcem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com