Drilling Construction Method of Double-layer Casing Reinforced Double-pipe Shed and Pipe in Railway Underpassing Highway Tunnel

A double-layer casing, highway tunnel technology, applied in tunnels, tunnel lining, earthwork drilling, etc., can solve problems such as safety accidents, small distance between tunnel floors, affecting the normal function of existing tunnels, etc., and achieve optimal design and construction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

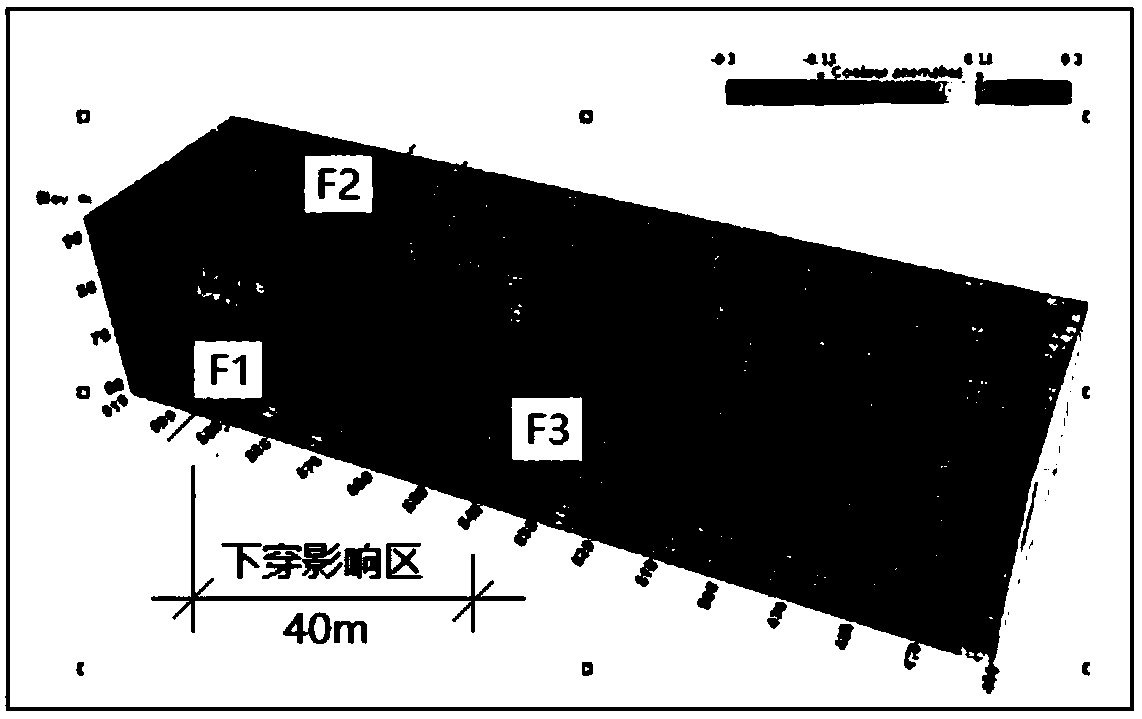

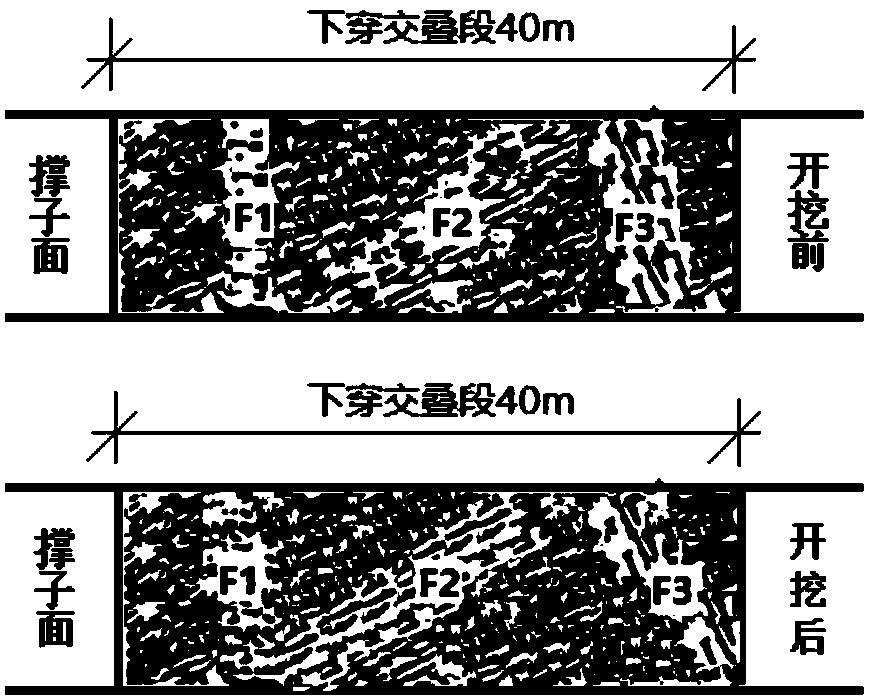

[0045] Such as Figure 9 The newly-built No. 2 Strawberry Valley Tunnel (double-track) in the DT2 section of the Qianyang-Zhuanghe Section of the Northeast East Railway Channel in Zhenxing District, Dandong City, Liaoning Province is SN-oriented, and it is connected with the existing Dantang Highway Pandaoling Left, The right panel is approximately right-angled, and the top of the new tunnel structure is 17.62m away from the road surface. The construction method is carried out by using the double-layer casing reinforced double-pipe shed and pipe drilling construction method of the railway passing through the highway tunnel.

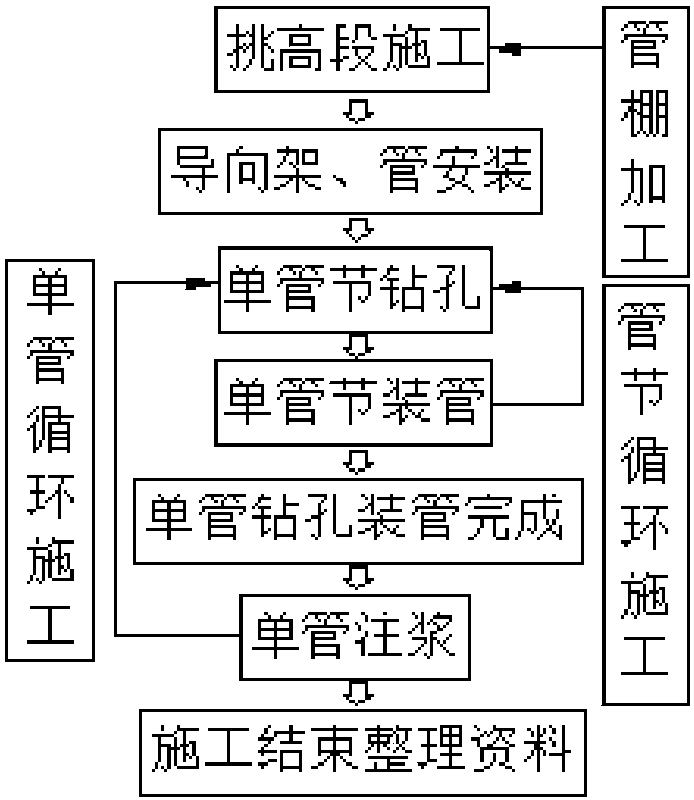

[0046] Specifically, the following steps are included: Figure 10 Shown:

[0047] 1) Construction preparation, existing tunnel disease investigation;

[0048] Under the influence of various factors such as water damage, lining corrosion, tunnel freezing damage, etc., the operating mountain tunnels have various diseases such as lining crack damage, tunn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com