Salt bath nitrocarburizing modifying method for surface of orthodontics arch wire

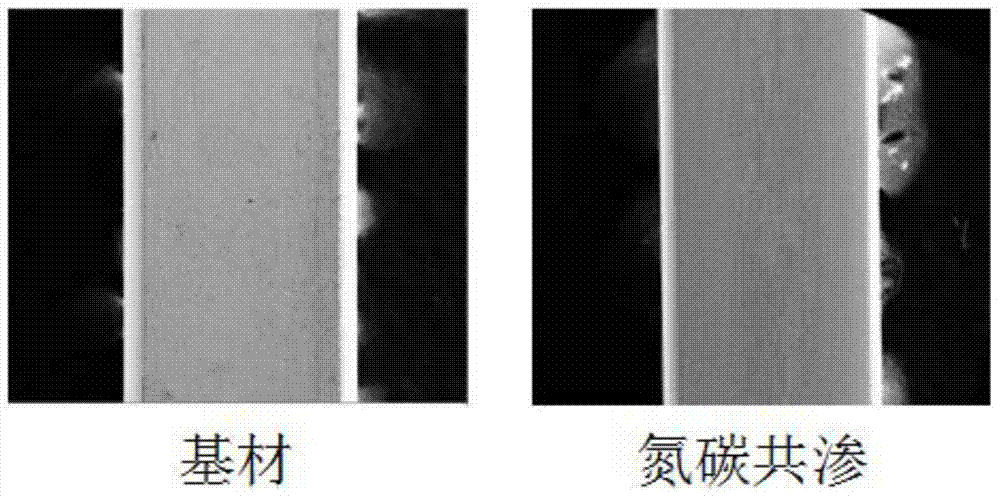

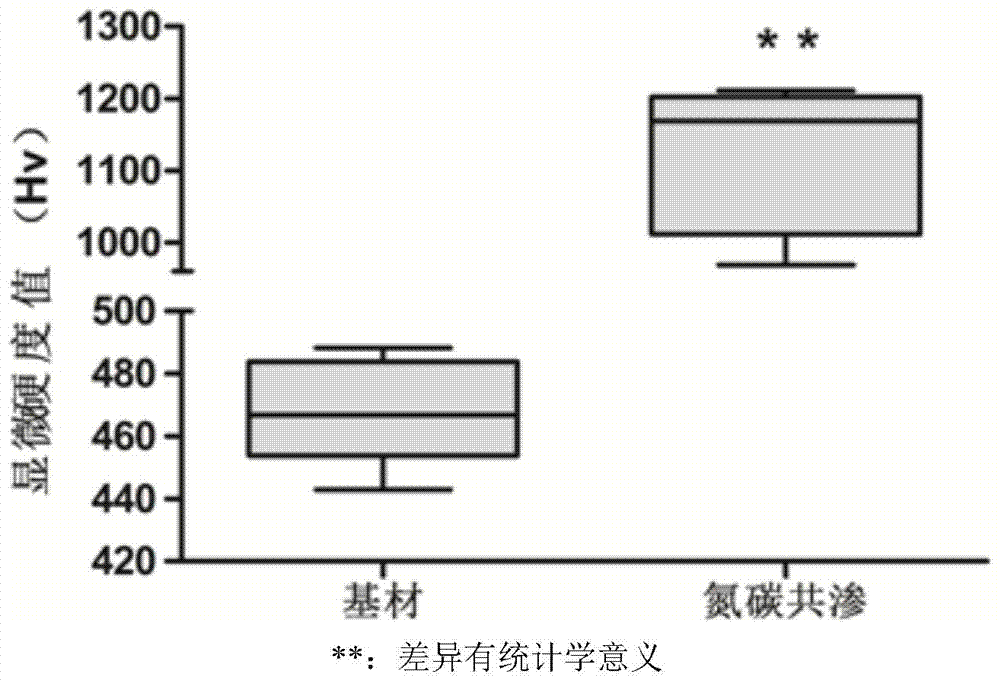

An orthodontic arch wire and nitrocarburizing technology is applied in the field of surface modification of biomedical materials to meet the needs of surface modification and clinical application, good biocompatibility, and improved corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

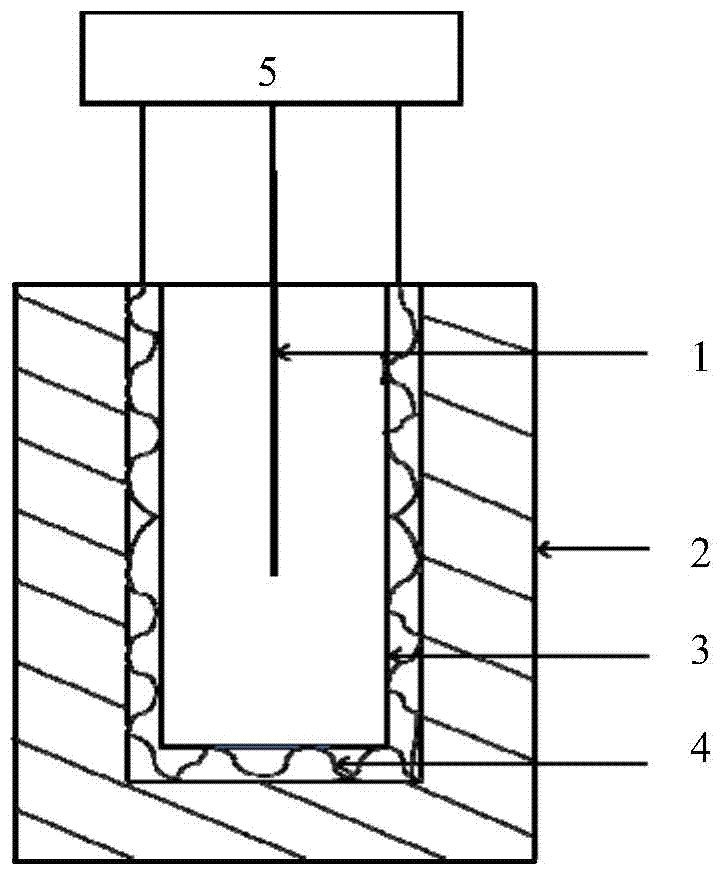

[0022] The present invention is realized through the following steps: (1) pretreatment of the surface of the arch wire, followed by ultrasonic cleaning in ethanol, acetone, and distilled water for 10 minutes to remove oil stains; (2) using a special penetrating agent for austenitic stainless steel on the pretreated arch wire Carry out salt bath nitrocarburizing, the salt bath temperature is 565°C, and the treatment time is 10 minutes; (3) The arch wire after nitrocarburizing treatment is cooled at room temperature for 30 minutes, and then ultrasonically cleaned with ethanol and acetone in sequence to obtain low surface friction Power stainless steel arch wire. The orthodontic arch wire is an austenitic stainless steel orthodontic arch wire, and the size of the arch wire is 0.019×0.025 feet (0.48×0.64mm). Wherein step (two) described austenitic stainless steel special penetration agent contains 16%wtK 2 CO 3 , 24%wtKCl and 60%wt urea, CNO - The mole fraction is controlled at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com