Aspheric reflector coating method based on low-temperature plasma surface modification

A low-temperature plasma and surface modification technology, applied in ion implantation plating, sputtering plating, gaseous chemical plating, etc., can solve the problems of film layer shedding, PMMA substrate easy to absorb moisture, etc. , the uniform effect of surface modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

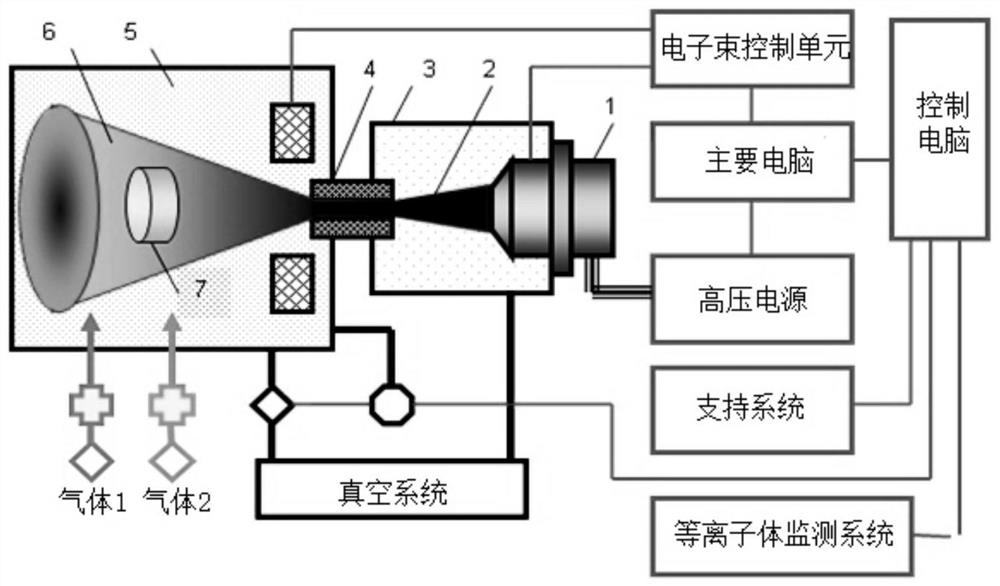

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0016] like figure 1 Shown, a kind of aspheric mirror coating method based on low temperature plasma surface modification, this method comprises the following steps:

[0017] Step 1, the support system is guaranteed to be connected with the control computer to maintain fast and normal operation. The control computer first controls the vacuum system to provide a vacuum environment for the coating, and then the control computer controls the main computer. The main computer controls the high-voltage power supply to make the electron gun emit electron beams. By changing The voltage of the high-voltage power supply changes the speed of the electron beam. The main computer controls the electron beam control unit. The electron beam control unit controls the movement direction of the electron beam by changing the voltage between the plates. The electron gun 1 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com