Preparation of kendir spinnable fiber

Apocynum and fiber technology, which is applied in the field of preparation of apocynum spinnable fibers, can solve the problems of destroying fiber spinnability, apocynum antibacterial and health-care properties, affecting comprehensive performance indexes of apocynum fibers, and high temperature of treatment liquid, and achieving spinnability. The effect of excellent performance, lower temperature and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

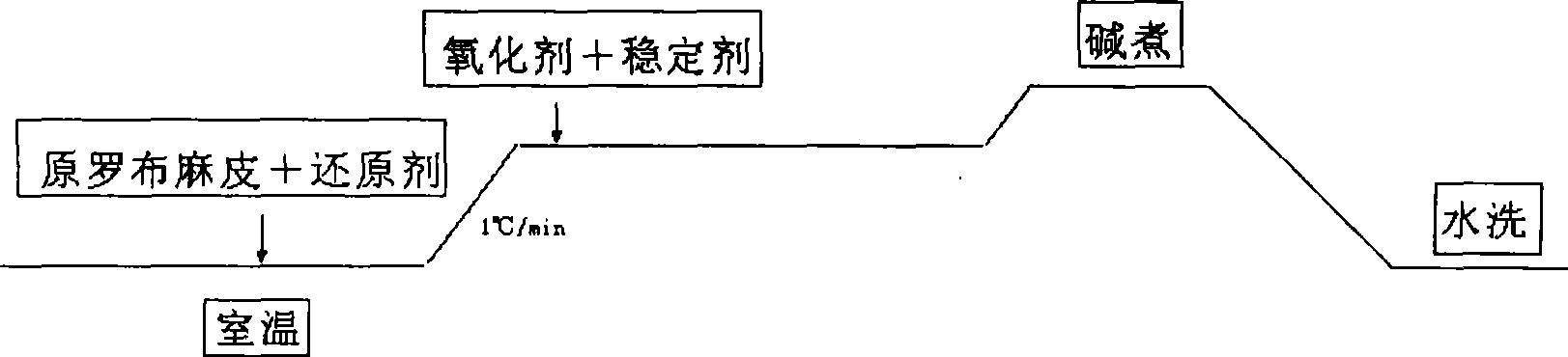

[0021] Such as figure 1 Shown: a kind of preparation method of apocynum spinnable fiber, comprises former apocynum husk activation treatment process, alkali boiling process, washing process, dehydration drying process:

[0022] The described activation treatment procedure of the former apocynum husk is: under the condition of room temperature, put the former apocynum husk into water, the bath ratio of the former apocynum husk to water is 1:25, then add thiourea to make the thiourea in the water The concentration of hydrogen peroxide in the water reaches 0.08mol / L, the temperature is raised to 65°C, and then 30% hydrogen peroxide and sodium silicate are added to make the concentration of hydrogen peroxide in water 0.25mol / L and the concentration of sodium silicate 0.18g / L. , The holding time is 80 minutes.

[0023] The alkali boiling process is as follows: the solution treated in the activation treatment process of the original apocynum bark is heated up to 75°C, and sodium hy...

Embodiment 2

[0026] A preparation method for spinnable fibers of apocynum, comprising an activation treatment process of the original apocynum husk, an alkali boiling process, a washing process, and a dehydration and drying process:

[0027] The described activation treatment process of the former apocynum husk is as follows: under the condition of room temperature, the former apocynum venetia husk is put into water, the bath ratio of the former venetia apocynum husk to water is 1: 28, then add urotropine to make the water The concentration of urotropine reaches 0.1mol / L, heat up to 70°C, then add potassium permanganate and sodium silicate, so that the concentration of potassium permanganate in water is 0.3mol / L, and the concentration of sodium silicate is 0.2 g / L sodium silicate, the holding time is 85 minutes.

[0028] The alkali boiling process is as follows: the solution treated in the activation treatment process of the original apocynum bark is warmed up to 80° C., adding sodium hydr...

Embodiment 3

[0031] A preparation method for spinnable fibers of apocynum, comprising an activation treatment process of the original apocynum husk, an alkali boiling process, a washing process, and a dehydration and drying process:

[0032] Described former apocynum husk activation process is: under the condition of room temperature, former apocynum husk is put into water, and the bath ratio of former apocynum husk and water is 1: 30, then adds glucose, makes the concentration of glucose in water reach 0.12mol / L, raise the temperature to 75°C, then add potassium persulfate and sodium silicate so that the concentration of potassium persulfate in water is 0.35mol / L, and the concentration of sodium silicate is 0.22g / L. The heat preservation time is 90 minutes.

[0033] The described alkali boiling process is: the solution treated by the original apocynum husk activation treatment process is warmed up to 85°C, and potassium hydroxide, sodium silicate, and sodium tripolyphosphate are added, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com