Superfine fiber polyurethane leather and base cloth as well as preparation method and application

A technology of ultra-fine fiber and polyurethane, applied in the direction of fiber processing, conjugated synthetic polymer artificial filament, non-woven fabric, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

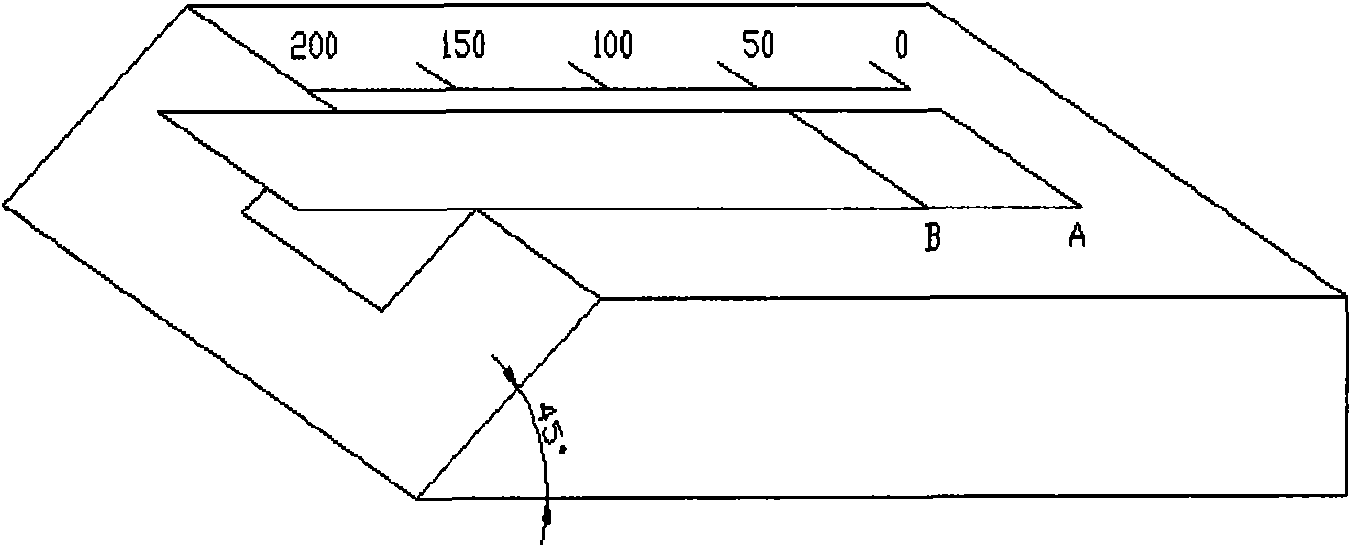

Image

Examples

Embodiment 1

[0051] Embodiment 1 The preparation of superfine fiber synthetic leather base cloth

[0052] Prepare the superfine fiber polyurethane synthetic leather base cloth according to the following steps successively: spinning, preparing non-woven fabric, ironing non-woven fabric (density is 0.28g / cm 3 ), impregnating the non-woven fabric in the polyurethane slurry, solidifying it in a DMF aqueous solution coagulation tank with a mass percent concentration of 40%, and then performing toluene decrementing, spreading, drying, oiling and tanning successively to obtain superfine fibers Polyurethane synthetic leather base fabric sample 1.

[0053] Wherein, the operation of spinning step is the nylon 6: low-density polyethylene (LDPE): FR-535 flame retardant color masterbatch (Japanese big printing ink chemical company) that the mass fraction ratio is=50: 50: 10, mix fully Finally, it is sent to the single-screw extruder for melt spinning, and after the first drawing and the second drawing...

Embodiment 2

[0057] Embodiment 2 Preparation of superfine fiber synthetic leather base cloth

[0058] The operation process is the same as in Example 1, but the polyurethane slurry is prepared according to the formula in Table 2 in the dipping step to obtain the superfine fiber polyurethane synthetic leather base cloth sample 2.

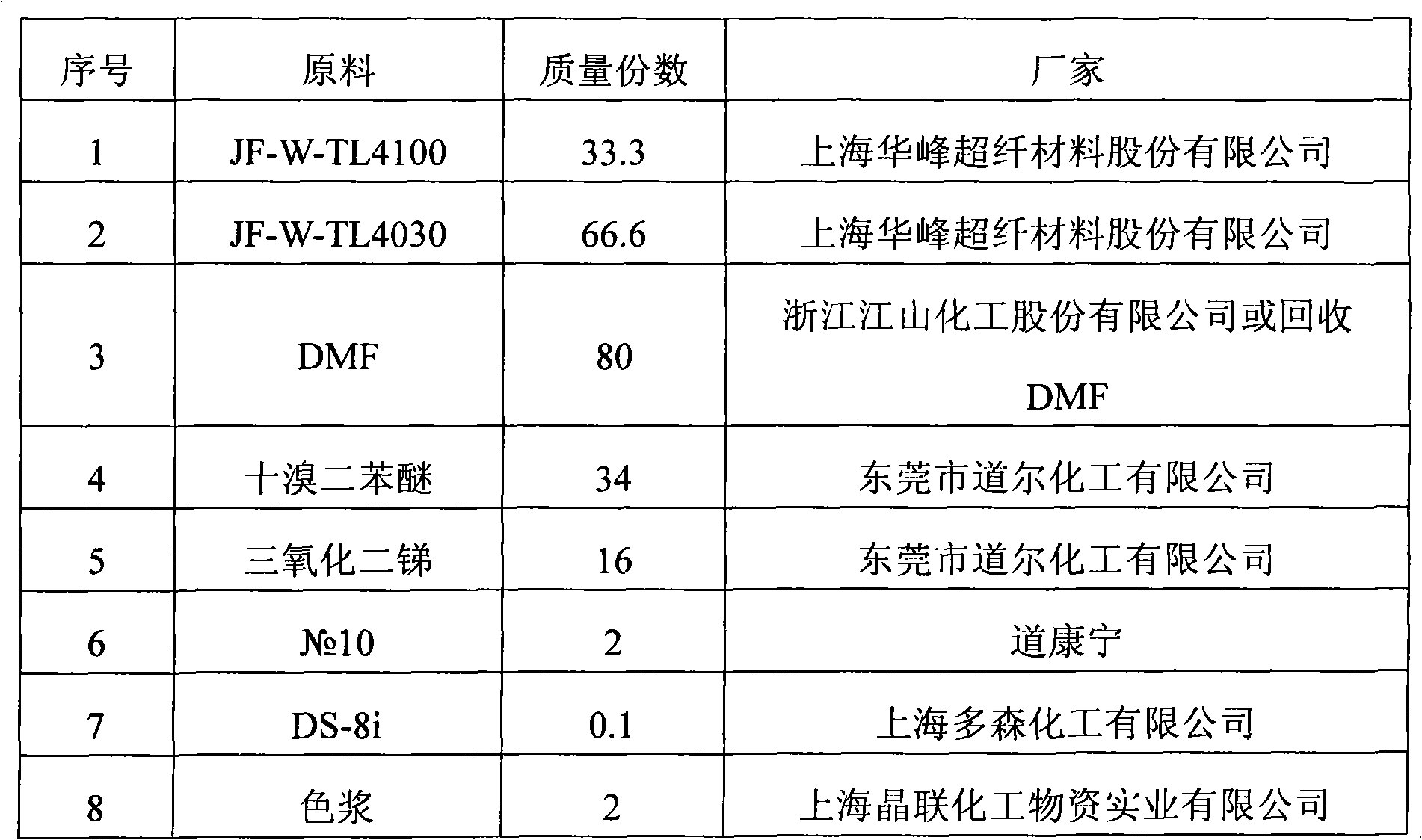

[0059] Table 2

[0060]

Embodiment 3

[0062] The operation process is the same as in Example 1, but the polyurethane slurry is prepared according to the formula in Table 3 in the dipping step to obtain the microfiber polyurethane synthetic leather base cloth sample 3.

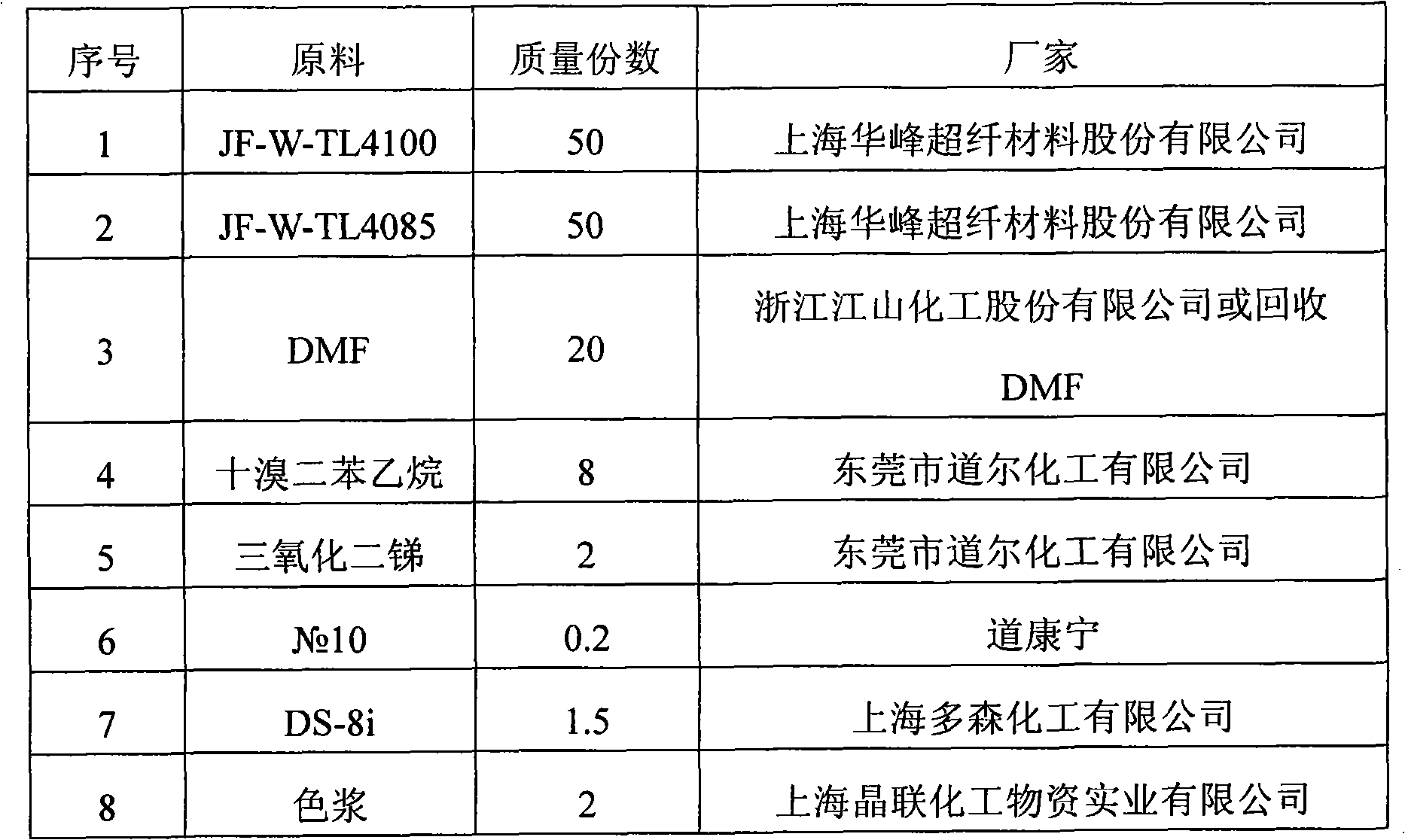

[0063] table 3

[0064]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com