Submicron aperture composite membrane based on heavy ion microporous membrane as well as preparation method and application thereof

A heavy ion microporous membrane and sub-micron technology, applied in the field of materials, can solve the problems of small flux, poor mechanical properties, thick filter material, etc., and achieve the effect of large flux, good product performance and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present invention provides a kind of preparation method for preparing the above-mentioned submicron pore composite membrane, comprising the following steps:

[0034] Step 1: Prepare materials, prepare ultra-thin heavy ion microporous membrane layer and support layer;

[0035] Step 2: Composite, stack the two layers of materials up and down, and compound the stacked two layers of materials by hot pressing. The hot pressing temperature is 100-280 degrees Celsius, specifically 130-280 degrees Celsius, and the pressure is 0.5-3 kg, specifically 1-2 kg;

[0036] Step 3: Etching. Put the compounded material into etching equipment for chemical etching. The etching solution used is a mixed solution of sodium hydroxide, potassium hydroxide, sodium hypochlorite or sulfuric acid and potassium permanganate. The etching temperature is 20-90 Celsius, specifically 30-40 Celsius, the concentration of the etching solution is 1%-30%, specifically 5%-10%, and the etching time is 10-5...

specific Embodiment 1

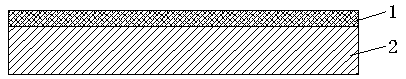

[0047] The present embodiment provides a submicron pore composite membrane based on heavy ion microporous membrane, comprising PET ultra-thin heavy ion microporous membrane layer and PET non-woven fabric, and described PET ultrathin heavy ion microporous membrane layer is compounded on PET on non-woven fabric.

[0048] The thickness of PET ultra-thin heavy ion microporous membrane layer is 1 micron, the pore diameter is 1 micron, and the pore density is 1×10 7 per square centimeter, the pore size of the PET non-woven fabric is 40 microns, and the thickness is 50 microns.

[0049] A method for preparing a submicron pore composite membrane based on a heavy ion microporous membrane as described above, comprising the following steps:

[0050] Step 1: Prepare materials, prepare ultra-thin heavy ion microporous membrane layer and support layer;

[0051] Step 2: Composite, stack the two layers of materials up and down together, and compound the stacked two layers of materials by ho...

specific Embodiment 2

[0055] This embodiment provides a submicron pore composite membrane based on the heavy ion microporous membrane, including PP ultra-thin heavy ion microporous membrane layer and PP non-woven fabric, and the PP ultrathin heavy ion microporous membrane layer is compounded on PP on non-woven fabric.

[0056] The thickness of the PP ultra-thin heavy ion microporous membrane layer is 0.5 microns, the pore diameter is 0.22 microns, and the pore density is 3×10 8 per square centimeter, the pore size of the PP non-woven fabric is 30 microns, and the thickness is 100 microns.

[0057] A method for preparing a submicron pore composite membrane based on a heavy ion microporous membrane as described above, comprising the following steps:

[0058] Step 1: Prepare materials, prepare ultra-thin heavy ion microporous membrane layer and support layer;

[0059] Step 2: Composite, stack the two layers of materials up and down, and compound the stacked two layers of materials by hot pressing. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com