Multicomponent high molecular composite construction sealing materials and production process thereof

A sealing material and polymer technology, which is applied in building thermal insulation materials, building components, chemical instruments and methods, etc., can solve the problems such as the production method of multi-polymer composite building sealing materials that have not been retrieved, and achieve chemical resistance and stability. Improved, improved performance, moderately priced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1、2

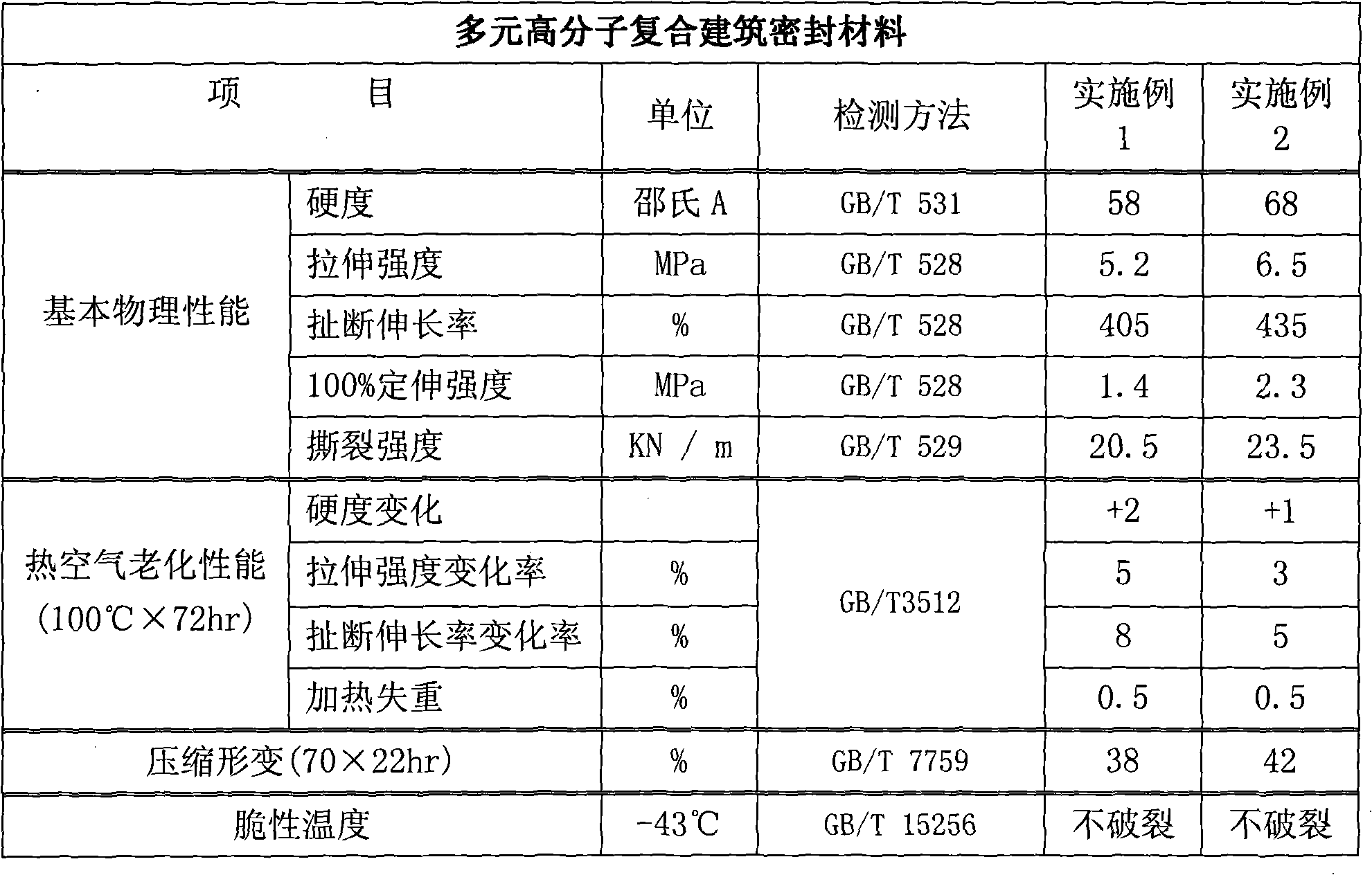

[0040] The formulations of each embodiment are shown in Table 1, and the corresponding product properties are shown in Table 2

[0041] Table 1:

[0042] Formula composition

Example 1

Example 2

55

45

25

30

Styrenic elastomer

15

20

EPDM

5

5

100

120

120

80

crosslinking agent

3

3

Auxiliary

2

2

[0043] Note: 1. In all formulations, the figures of content represent parts by weight.

[0044] 2. The filler is light calcium carbonate treated with 800 mesh surface coupling activation.

[0045] 3. The plasticizer is naphthenic rubber filler oil.

[0046] 4. The cross-linking agent adopts organic dicumyl peroxide (DCP).

[0047] 5. The additives are antioxidants, polyethylene waxes and other additives.

[0048] Preparation:

[0049] ① Take ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com