Method for producing nano graphite field emission vacuum electronic cathode

A technology of nano-graphite and vacuum electronics, applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of complex production process, large volume, low production efficiency, etc., and achieve easy industrial production and production The effect of simple process and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

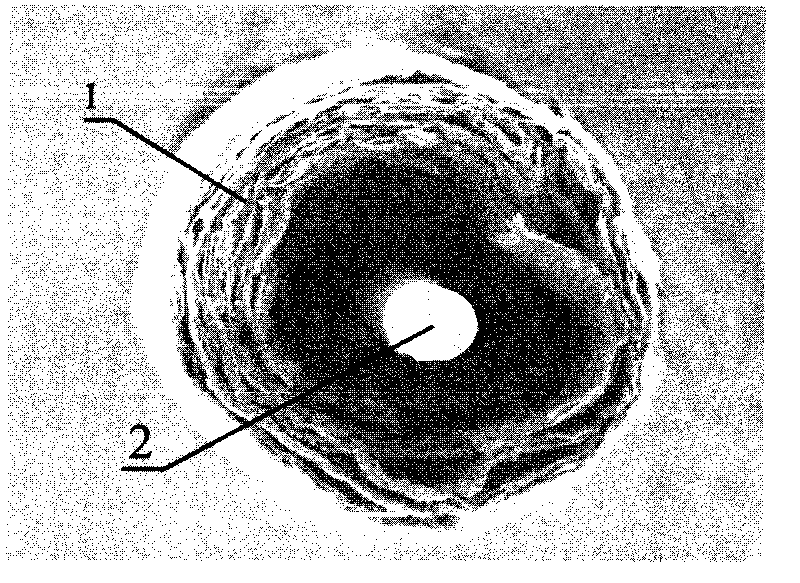

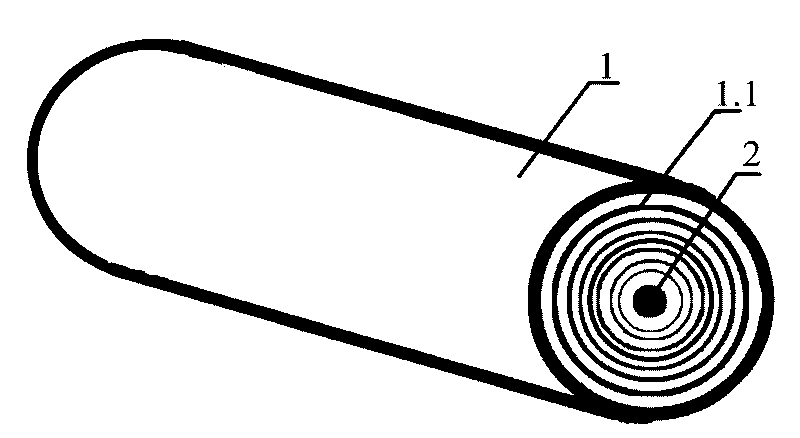

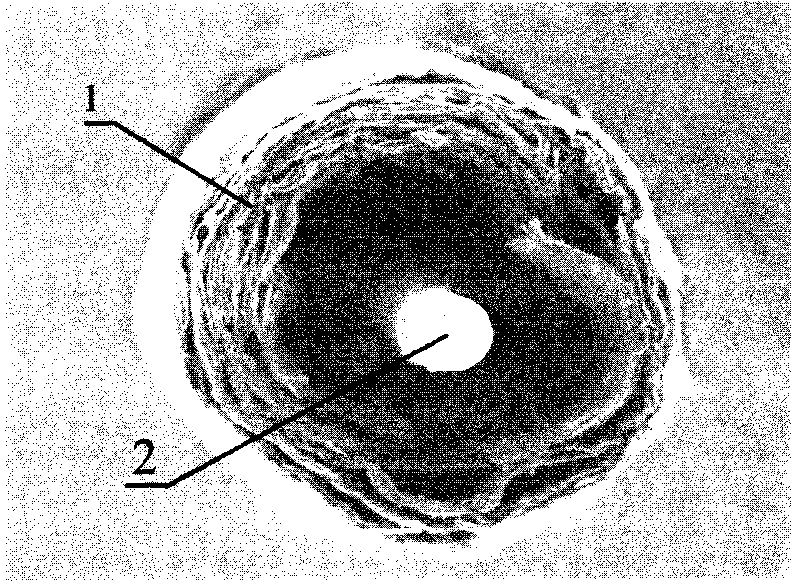

Image

Examples

Embodiment Construction

[0016] A. Put 4.0g of industrial expanded graphite with a thickness of 0.1-100μm into a high-temperature-resistant container, heat it at 800±20°C to fully expand it, and obtain worm-like expanded graphite;

[0017] B. be after the industrial concentrated sulfuric acid 500ml of 96% and 1.0g potassium permanganate are mixed with solution with concentration, add step A gained expanded graphite, oxidize to thickness≤1nm, side length is the nano-graphite sheet (sheet) of 1-10 μm shape particles), the resulting mixed solution containing nano-graphite flakes is transferred to step C;

[0018] C. After filtering the mixed solution obtained in step B, washing with water to remove acid, then placing it in deionized water, performing ultrasonic and centrifugal purification treatment under the condition of ultrasonic frequency of 100KHz and power of 50W, and collecting the upper layer after the impurities are separated at the bottom Liquid, obtain the suspension of dispersed oxidized grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com