Molding method of hollow body with built-in component

A molding method and hollow body technology, which can be applied to hollow objects, other household appliances, household appliances, etc., can solve the problems of easy adhesion of blanks, easy leakage of hydrocarbons, unfavorable low evaporative emissions, etc., and achieve cost savings. , The way to reduce leakage, the effect of reducing the weight of the lower flash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to deepen the understanding of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings; the hollow body in this embodiment refers to the oil tank.

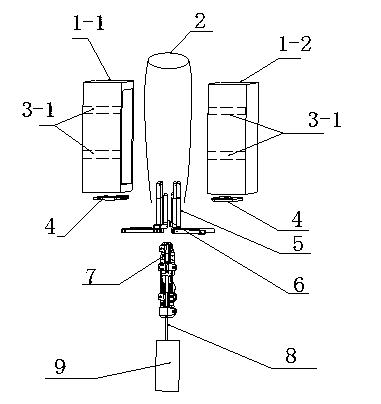

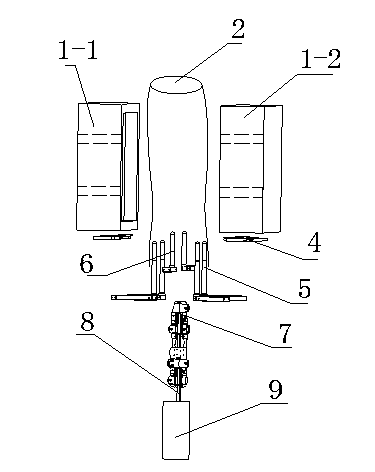

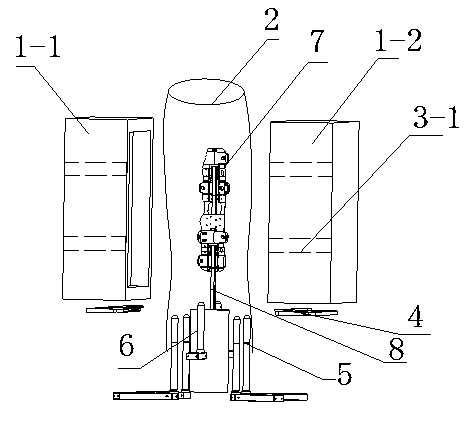

[0047] see figure 1 , 2 :

[0048] First, install the built-in component with a manipulator on the built-in component fixing rod 8 at the lower end of the blank 2, the built-in component fixing rod 8 is fixed on the built-in component fixing device 9, the fixing rod 8 drops to the position and returns to the waiting position, and the four stretching rods 5 and The two expansion rods 6 are closed, and the distance between the four stretching rods and the two expansion rods is reduced as much as possible, so that the blank can be inserted into the stretching rod smoothly. When the stretching device is completely closed, the cylindrical The billet 2 is extruded from the upper end and descends slowly; the tubular billet is extruded and inserted i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com