Method for producing cottonseed germ materials used in low-temperature pretreatment production of gossypol-removed cottonseed protein

A technology of dephenolized cottonseed protein and low-temperature pretreatment is applied in the field of vegetable protein production, which can solve the problems of loss of nutritional value, high content, protein denaturation in cottonseed meal, etc., and achieves less billet powder, simple production process, and process performance. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

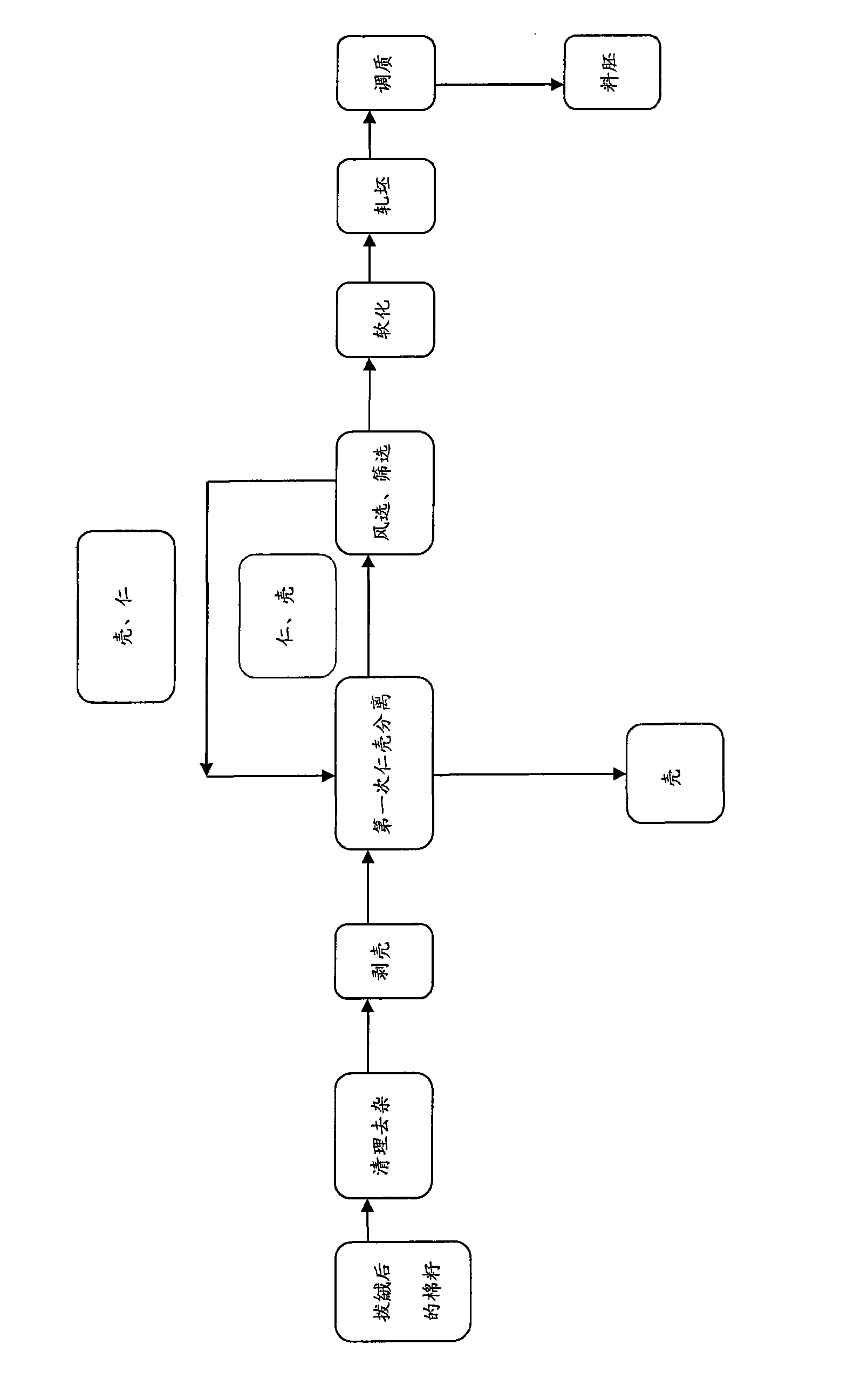

[0049] Such as figure 1 As shown, this embodiment provides a method for producing cottonseed embryos for low-temperature pretreatment to produce dephenolized cottonseed protein. The specific production steps are:

[0050]a. Use cottonseed with a water content of 9-13% and a cashmere content of 2-4%, and remove impurities by air selection, or use air selection and magnetic separation at the same time, so that the impurity content of cottonseed is ≤0.5%. Adjust so that only lint and impurities are blown out, and 2, 3, 4% are optional cottonseed lint content; too high or too low water content of raw cottonseed will affect the normal progress of subsequent processes, water content 9, 11, 13% are optional raw material cottonseed;

[0051] b. Input the cottonseed after removing impurities into the sheller for shelling treatment, and obtain the mixture of cottonseed hulls and cottonseed kernels. The feeding should be uniform and stable. Observe the material at the inlet and outlet o...

Embodiment 2

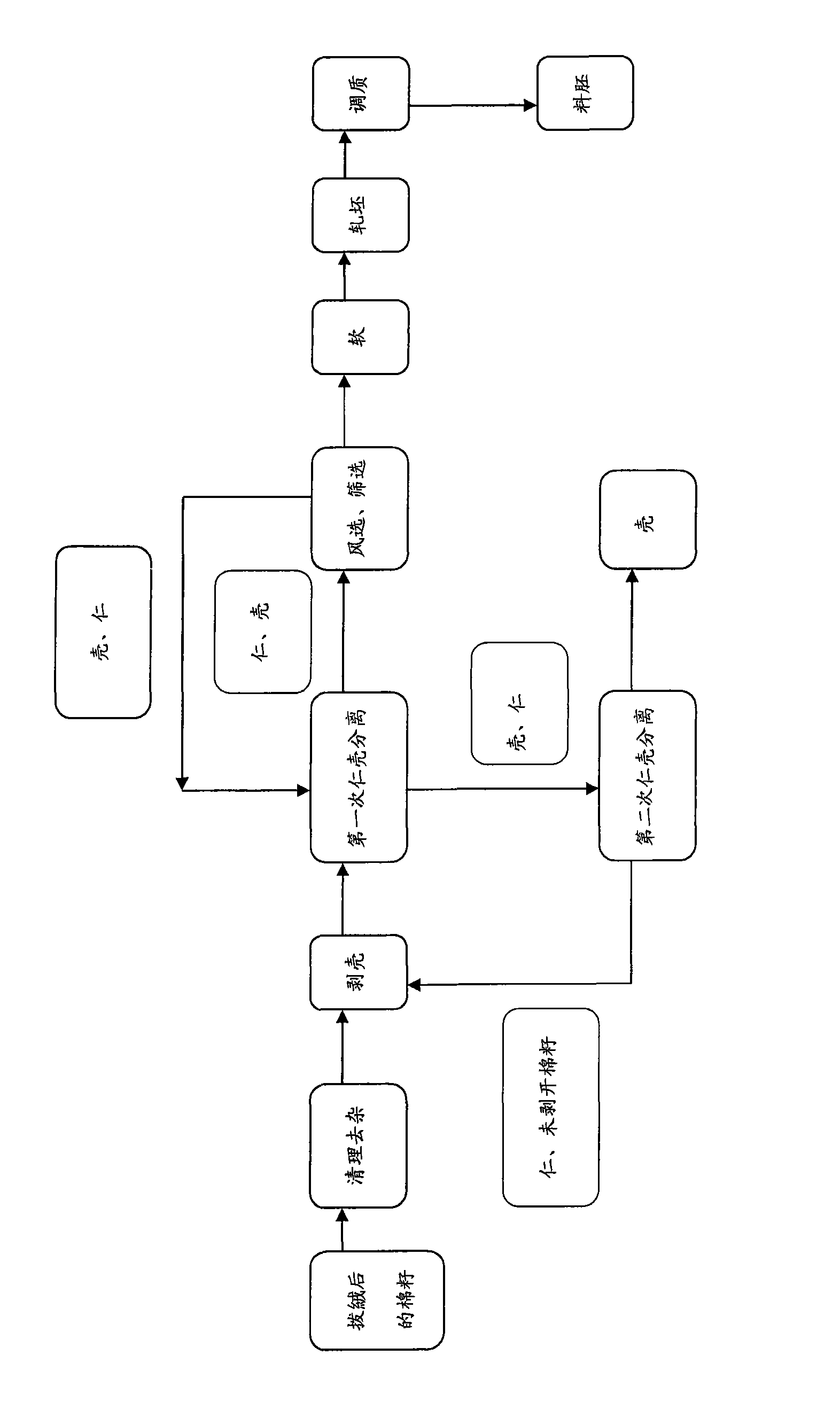

[0061] Such as figure 2 As shown, this embodiment provides a method for producing cottonseed embryos for low-temperature pretreatment to produce dephenolized cottonseed protein. The specific production steps are:

[0062] a. Use cottonseed with a water content of 7-16% and a velvet content of 2-6%, and remove impurities through winnowing, or winnowing and magnetic separation, so that the impurity content of cottonseed is ≤0.5%, and the air volume of winnowing is adjusted So that only lint and impurities are blown out, 2, 3, 4, 5, 6% are optional cottonseed velvet content; too high or too low moisture content of raw cottonseed will affect the normal progress of subsequent processes, moisture content 7 , 9, 11, 13, and 16% are all optional raw material cottonseed;

[0063] b. Input the cottonseed after removing impurities into the sheller for shelling treatment, and obtain the mixture of cottonseed hulls and cottonseed kernels. The feeding should be uniform and stable. Observe...

Embodiment 3

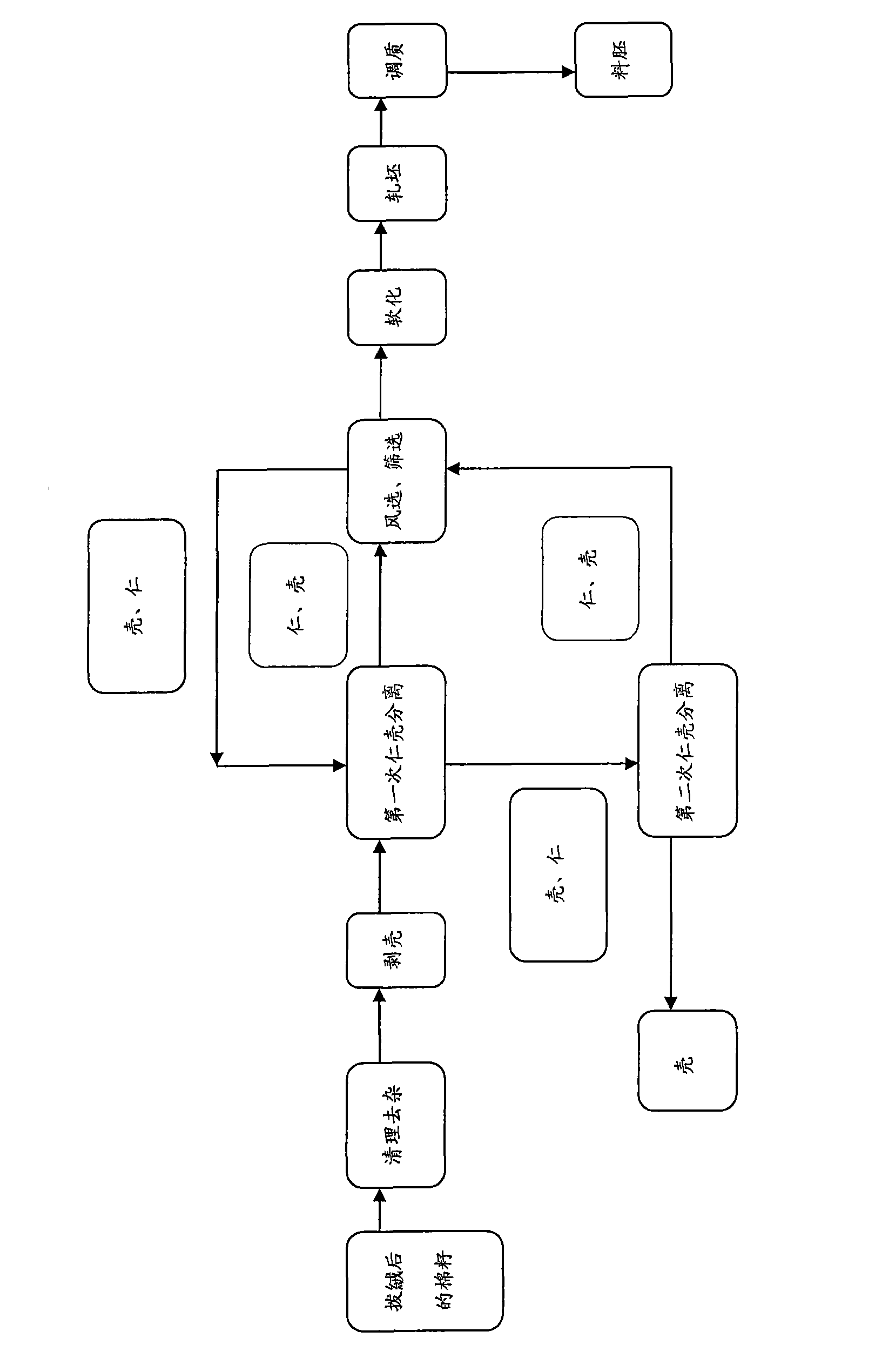

[0073] see image 3 , the present embodiment provides a method for producing cottonseed embryos for low-temperature pretreatment to produce dephenolized cottonseed protein, the specific steps of which are:

[0074] a. Use cottonseed with a water content of 7-16% and a velvet content of 2-6%, and remove impurities through winnowing, or winnowing and magnetic separation, so that the impurity content of cottonseed is ≤0.5%, and the air volume of winnowing Adjust so that only lint and impurities are blown out, 2, 3, 4, 5, 6% are optional cottonseed velvet content; too high or too low moisture content of raw cottonseed will affect the normal progress of subsequent processes, moisture content 7, 9, 11, 13, 16% are all optional raw material cottonseed;

[0075] b. Input the cottonseed after removing impurities into the sheller for shelling treatment, and obtain the mixture of cottonseed hulls and cottonseed kernels. The feeding should be uniform and stable. Observe the material at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com