Patents

Literature

77results about "Vegetable/imitation parchment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

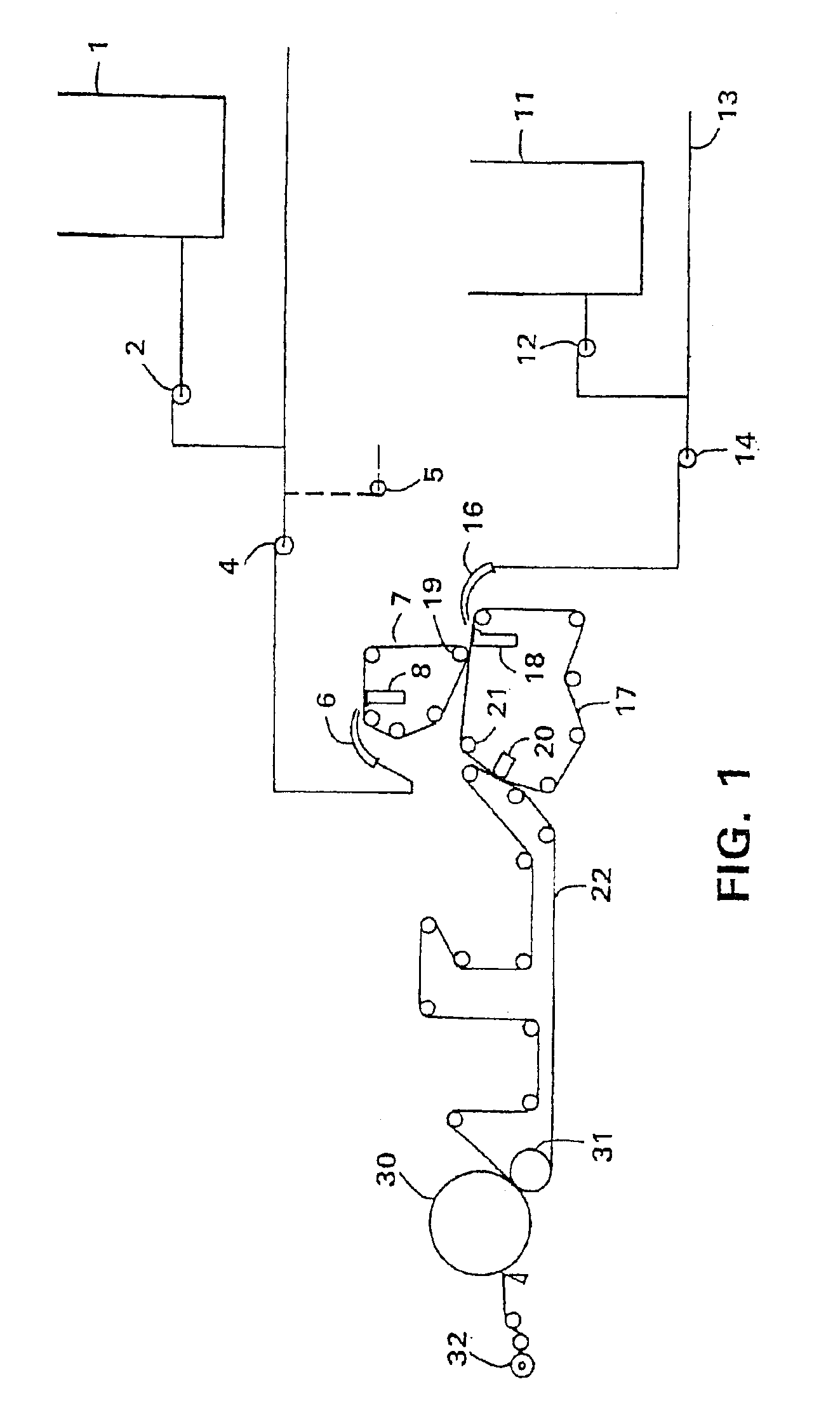

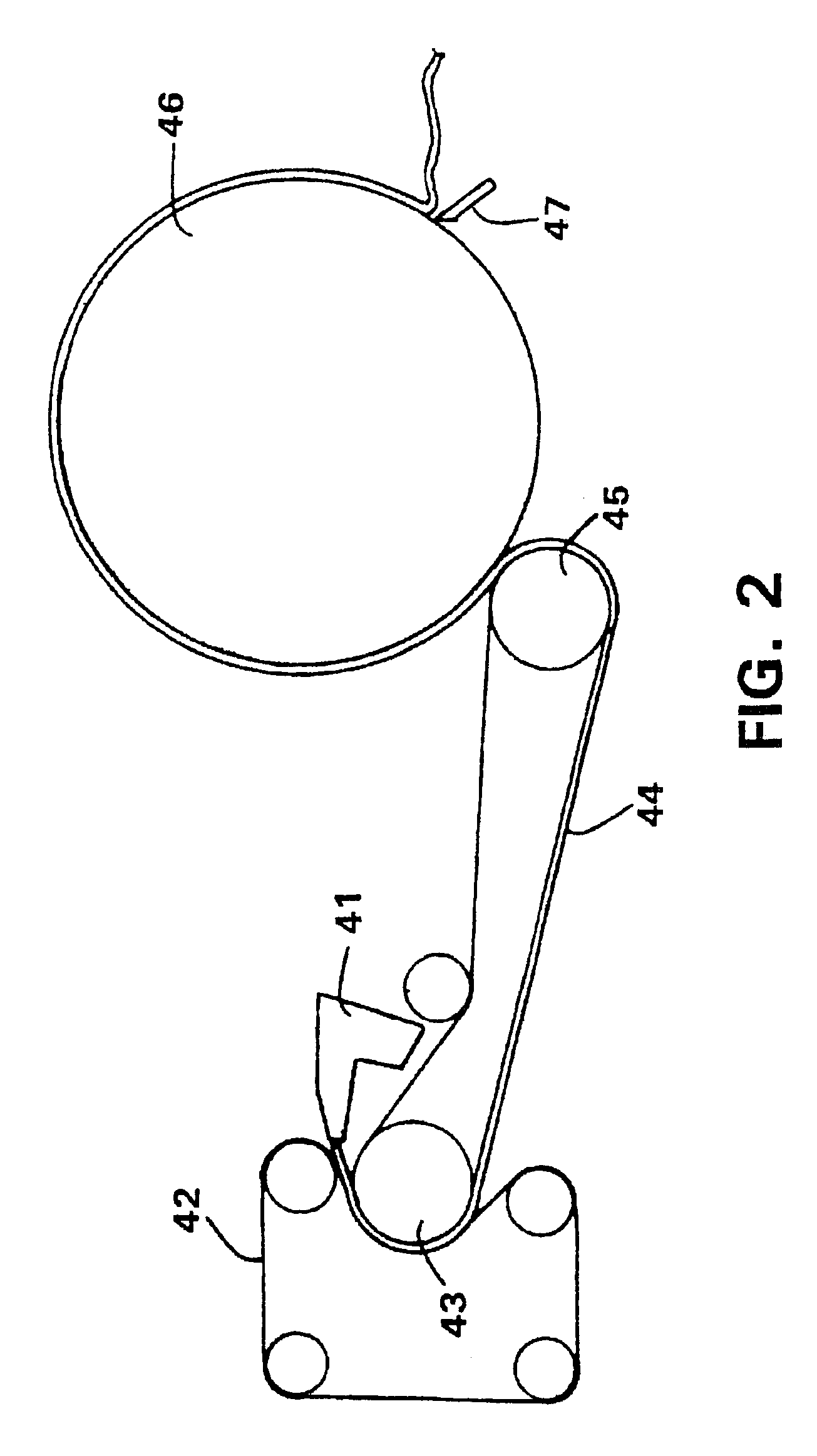

Method and apparatus for manufacturing microfibrillated cellulose fiber

ActiveUS7381294B2Efficient and stable productionQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberSlurry

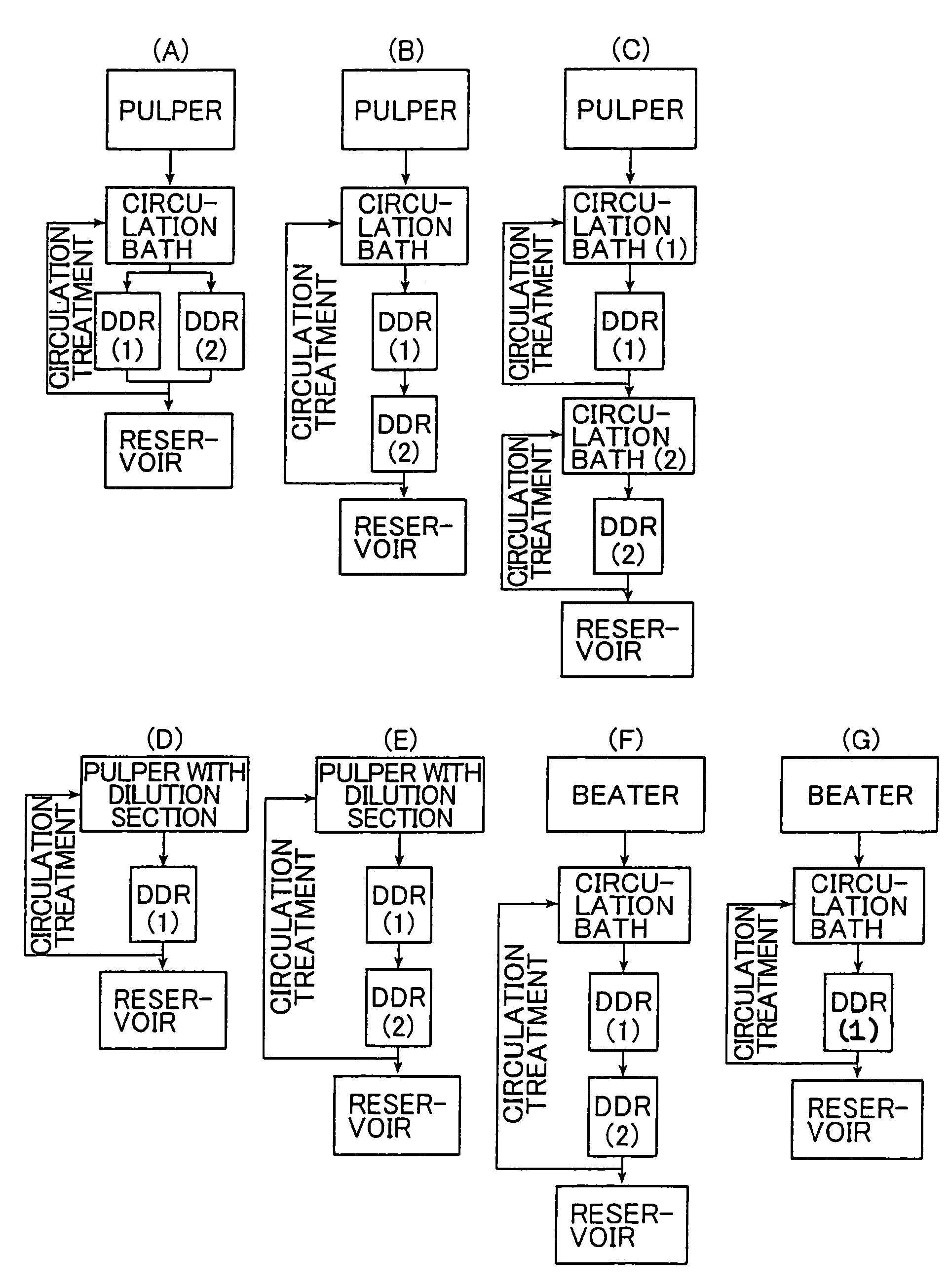

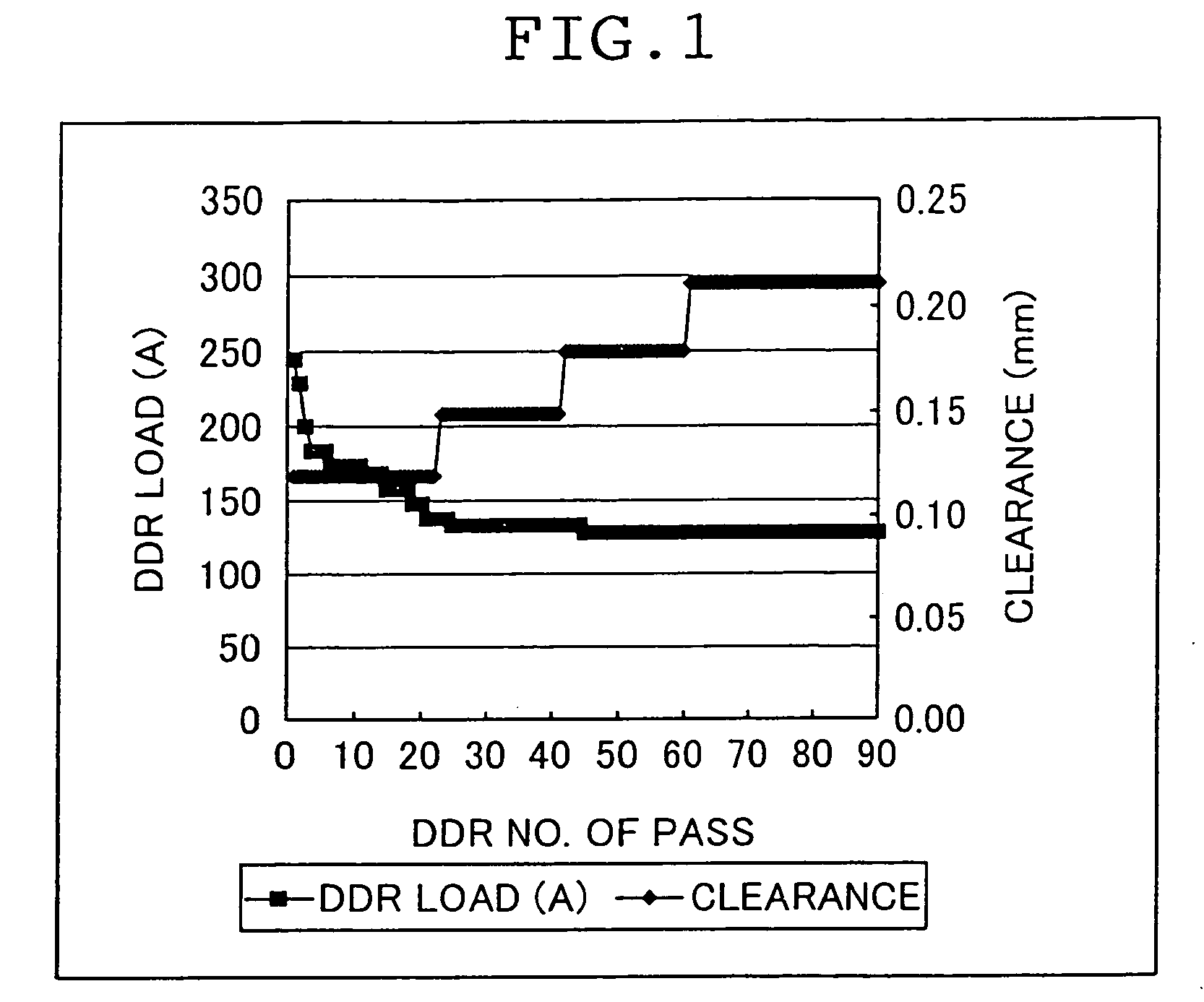

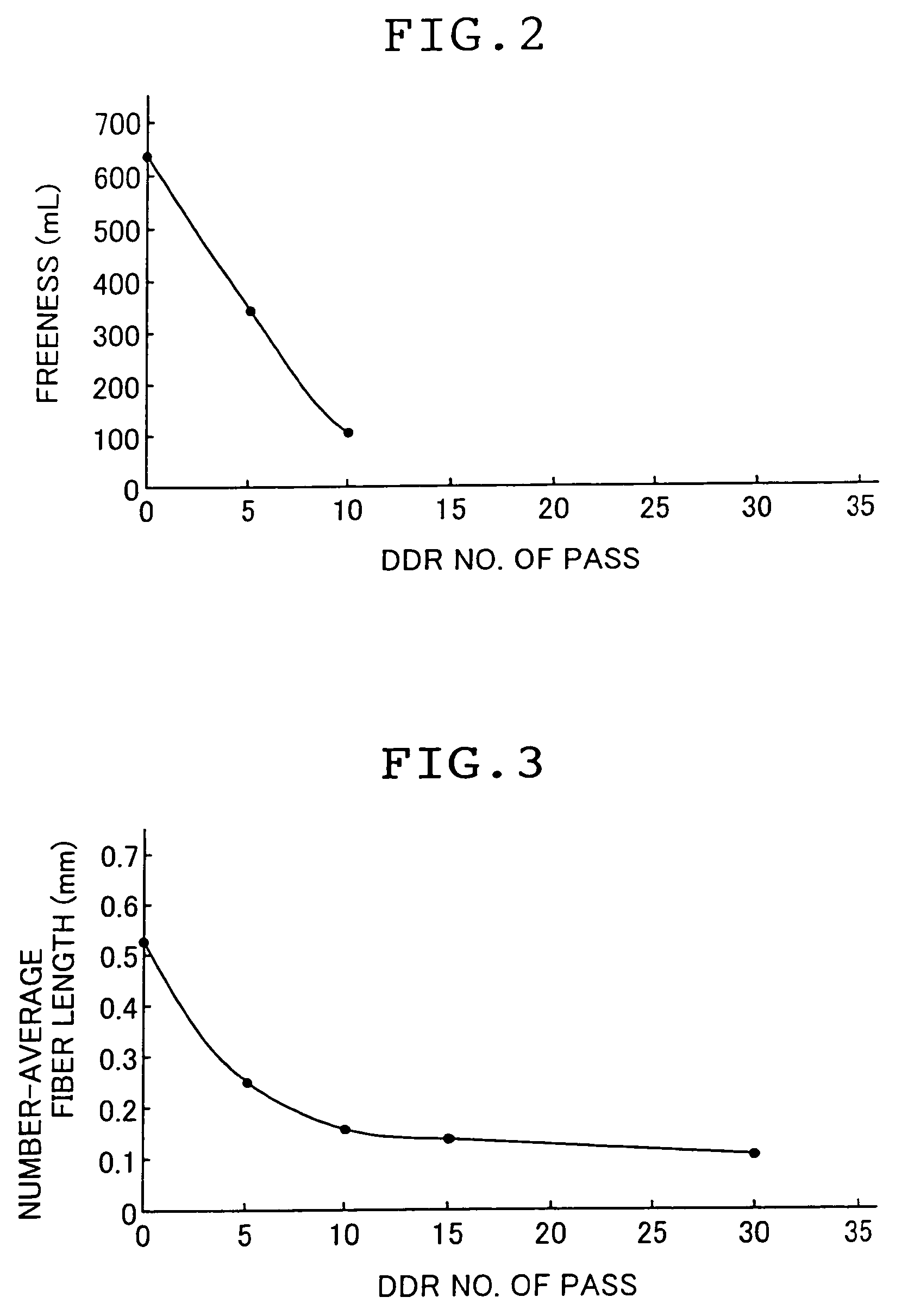

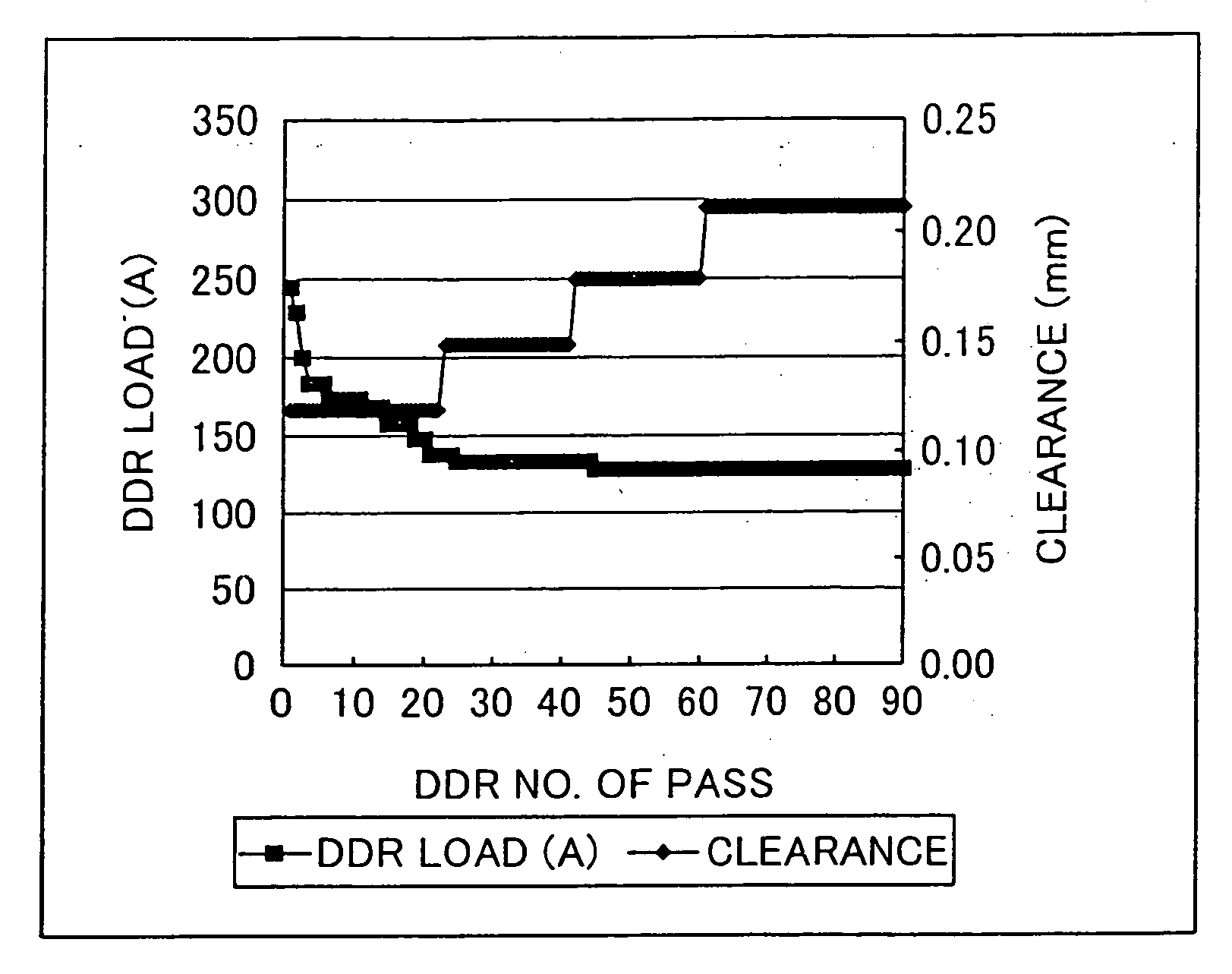

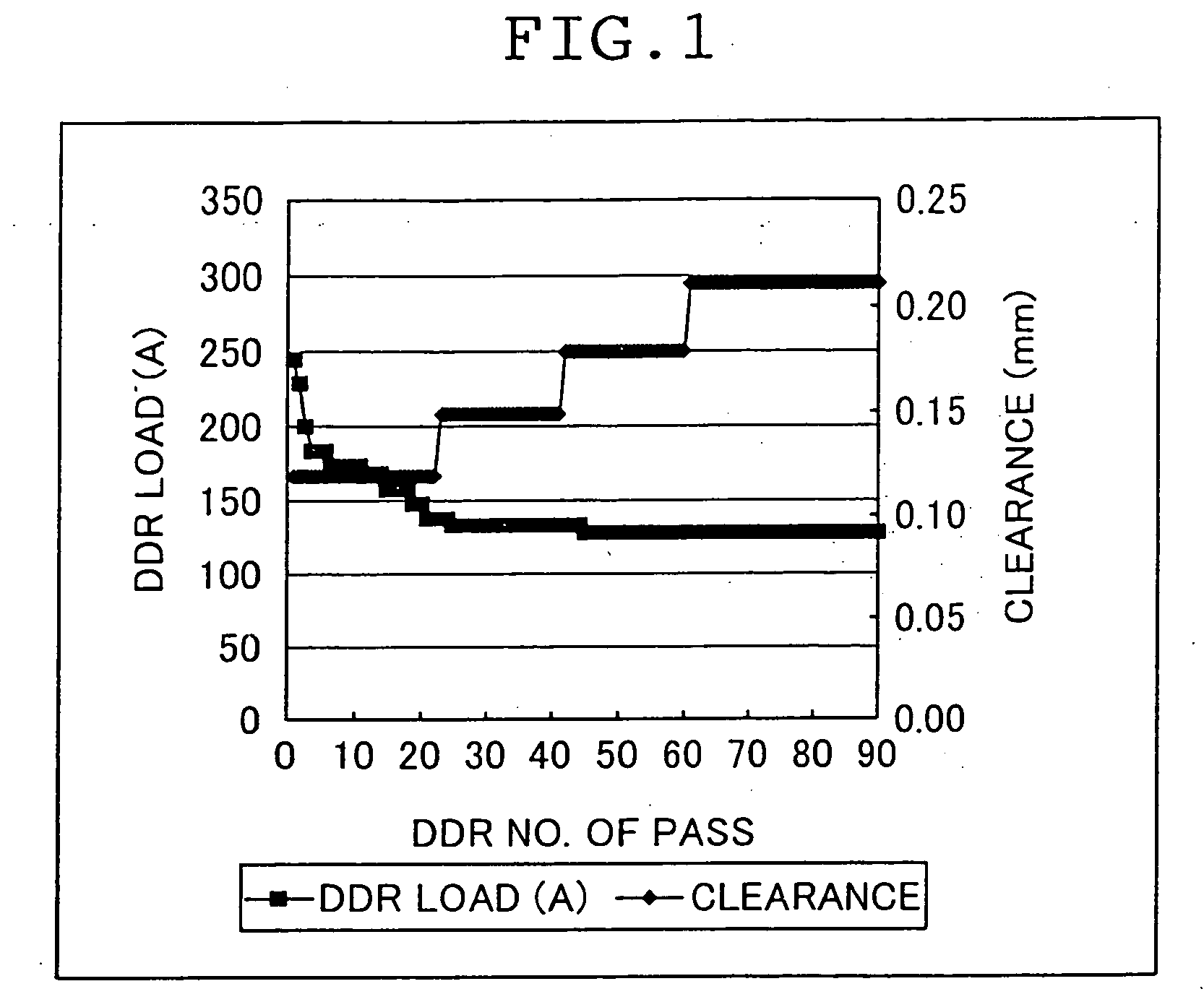

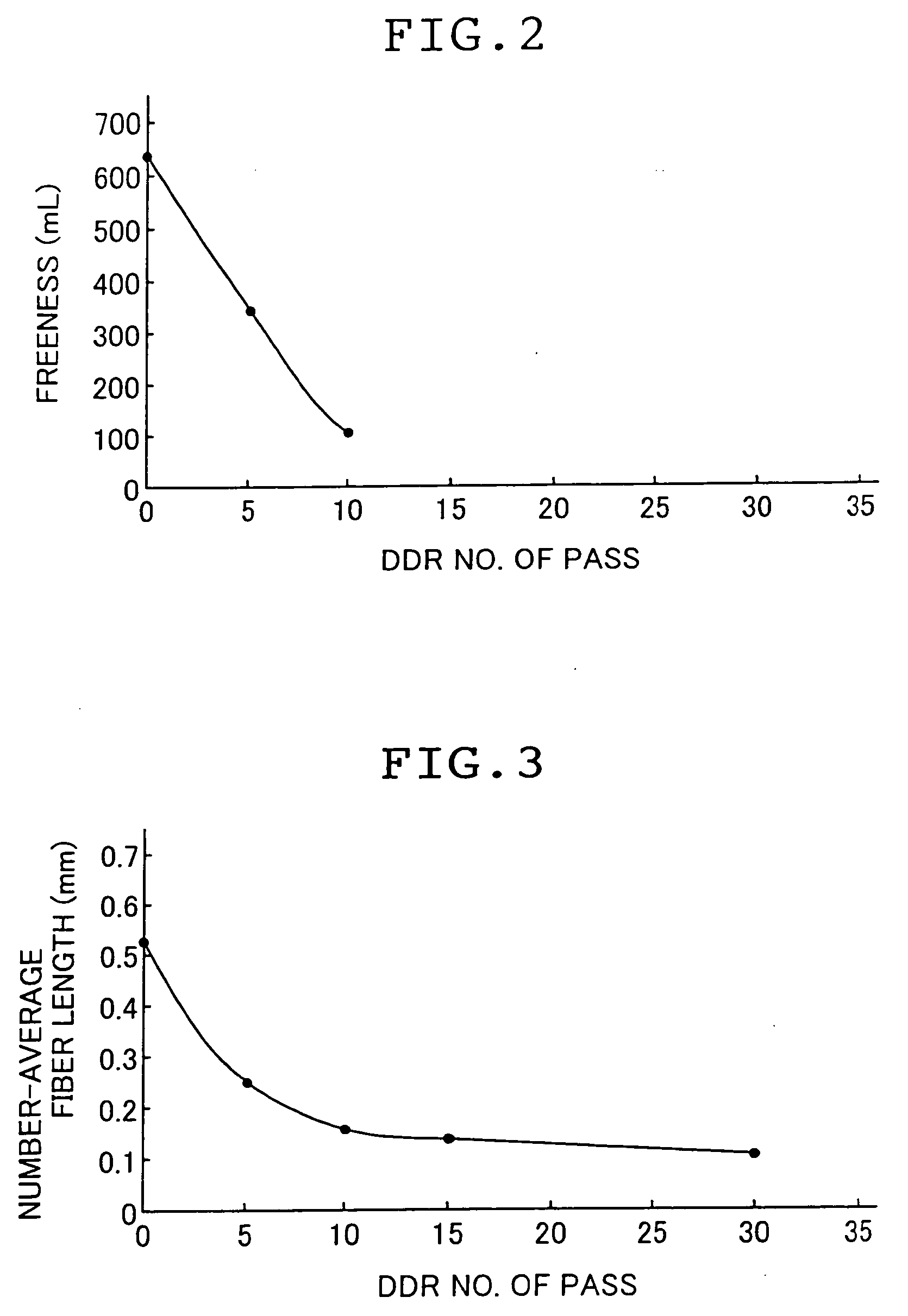

A method for producing a microfibrillated cellulose, which comprises subjecting a slurry containing a pulp having a solids concentration of 1 to 6 wt % to the treatment with a disc refiner repeatedly ten times or more, to thereby prepare a microfibrillated cellulose having a number average fiber length or 0.2 mm or less and an amount of water hold of 10 mL / g or more, the amount representing the volume of water capable of being held by a unit weight of the cellulose fiber. The method allows the production of a microfibrillated cellulose having high quality with stability and with good efficiency.

Owner:DSG INT LTD

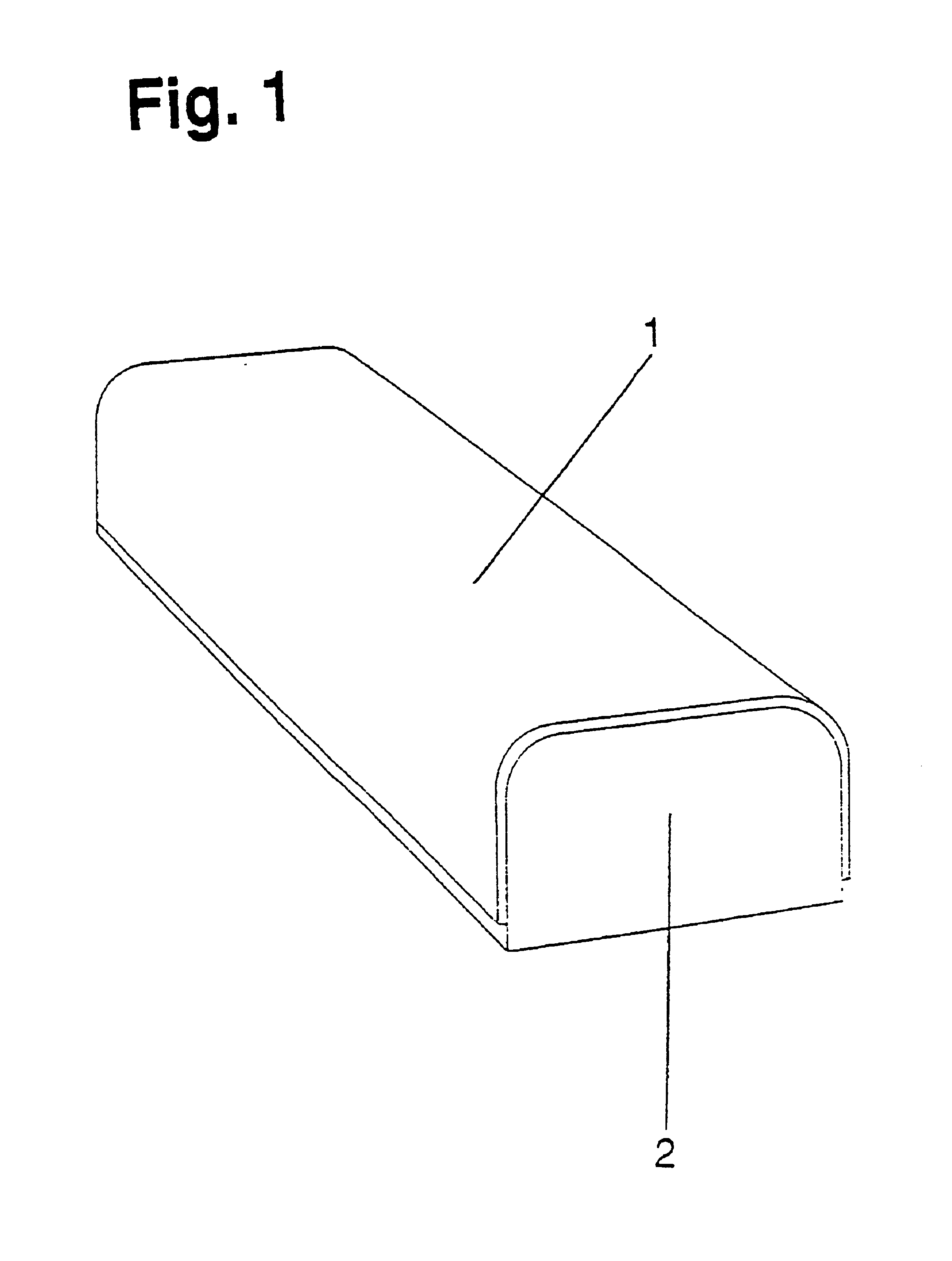

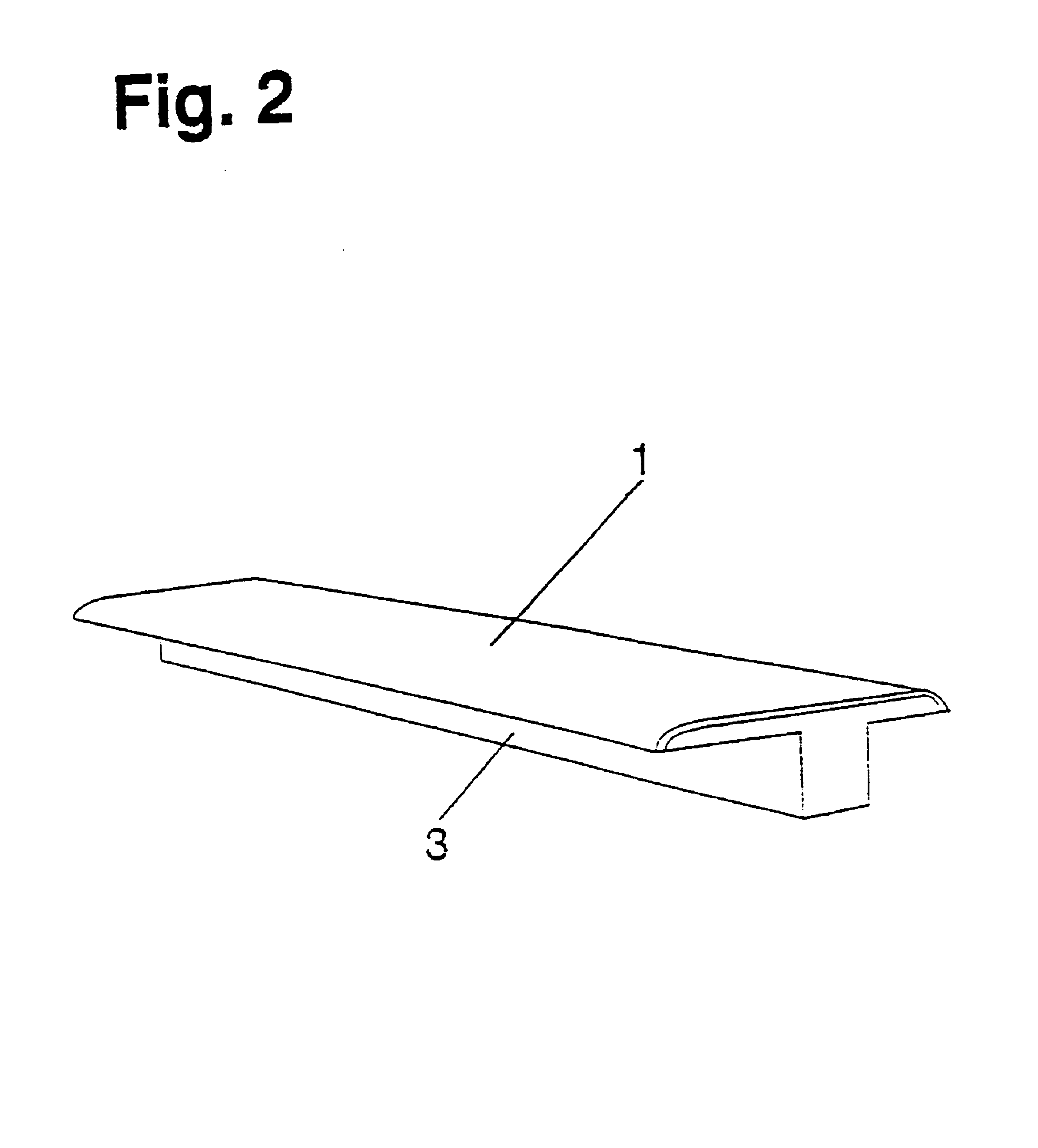

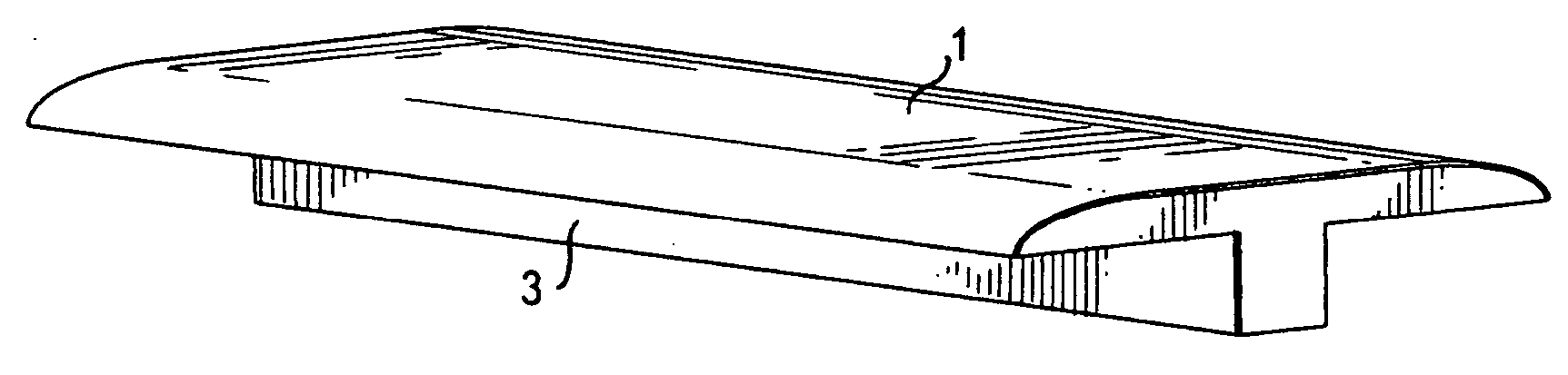

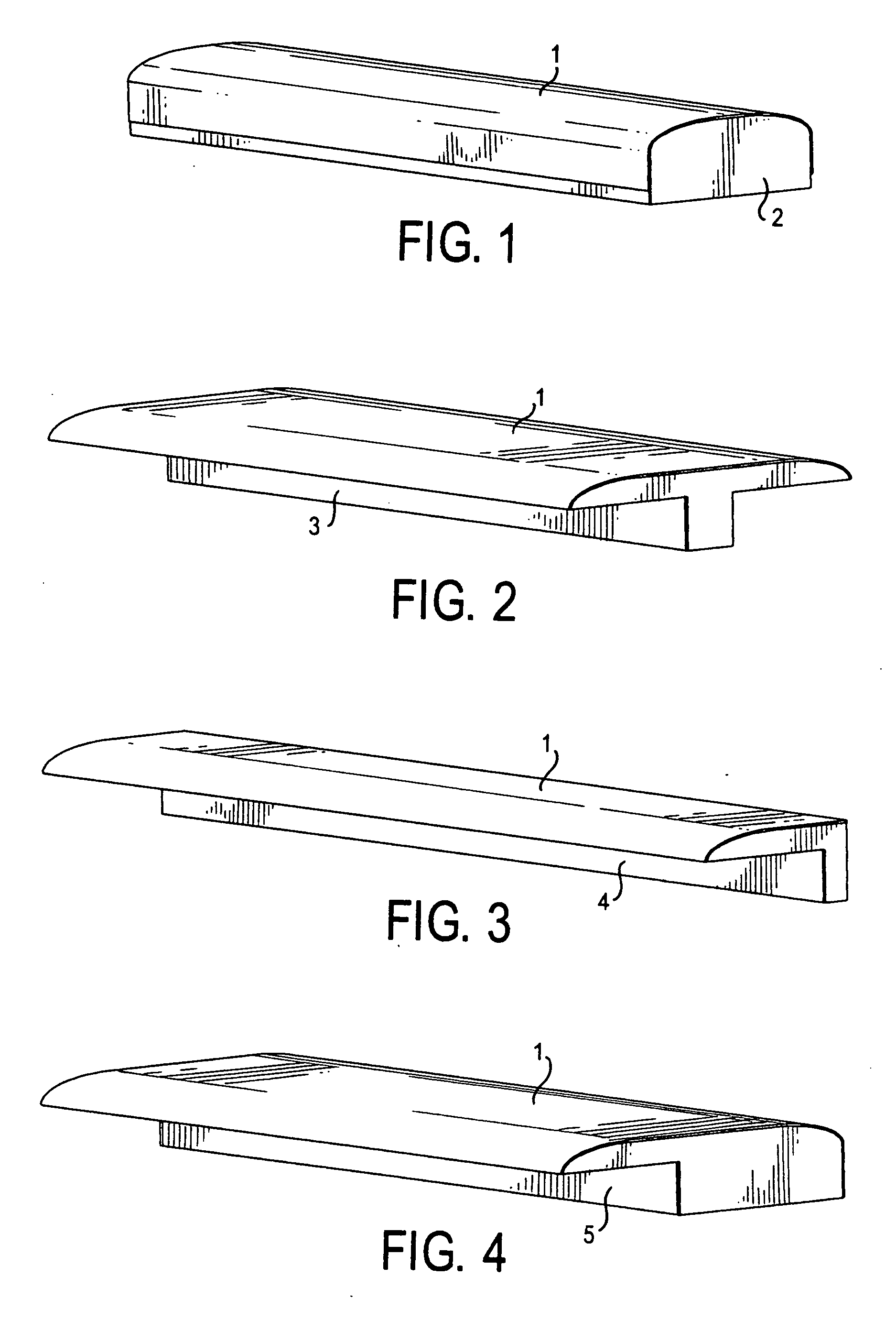

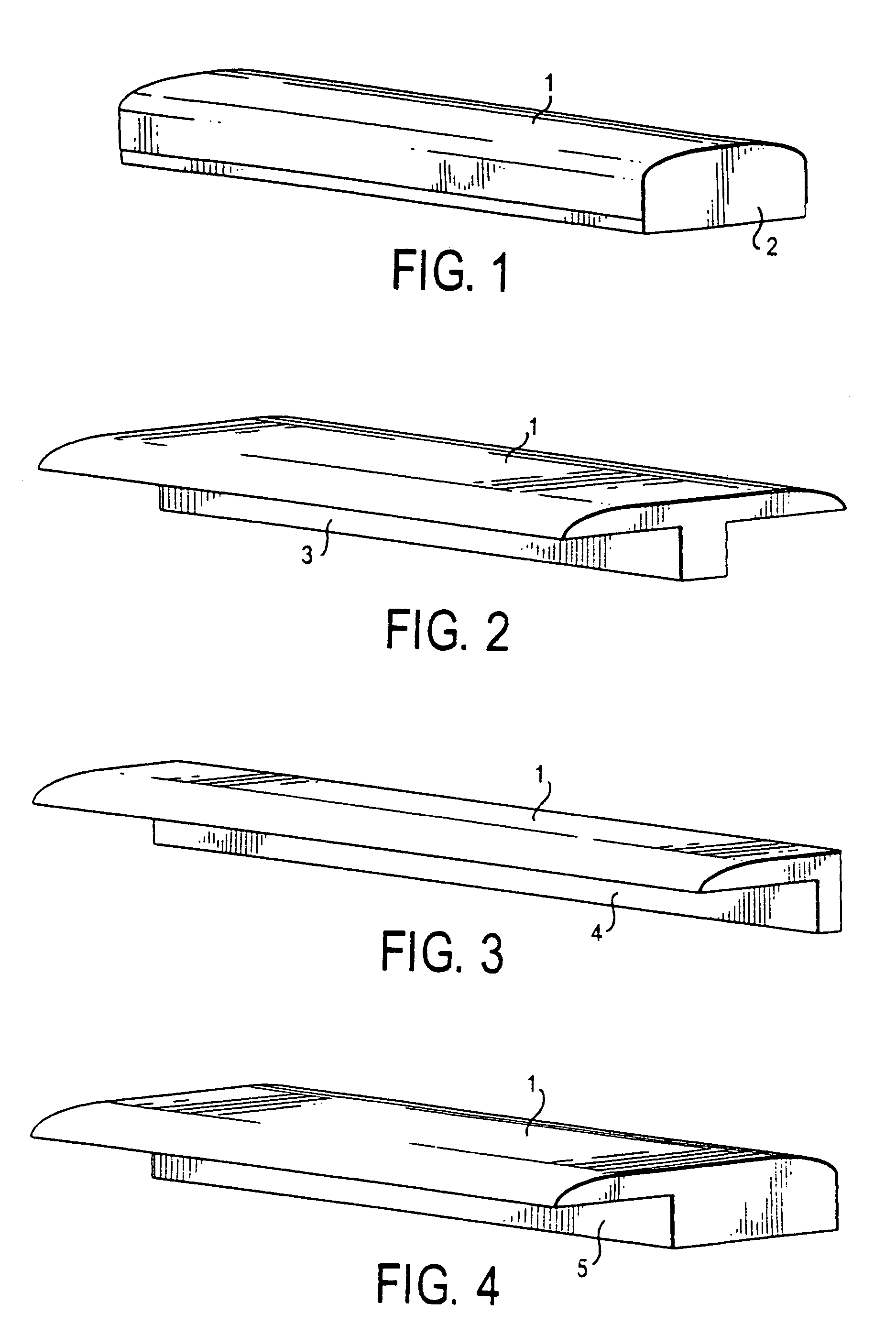

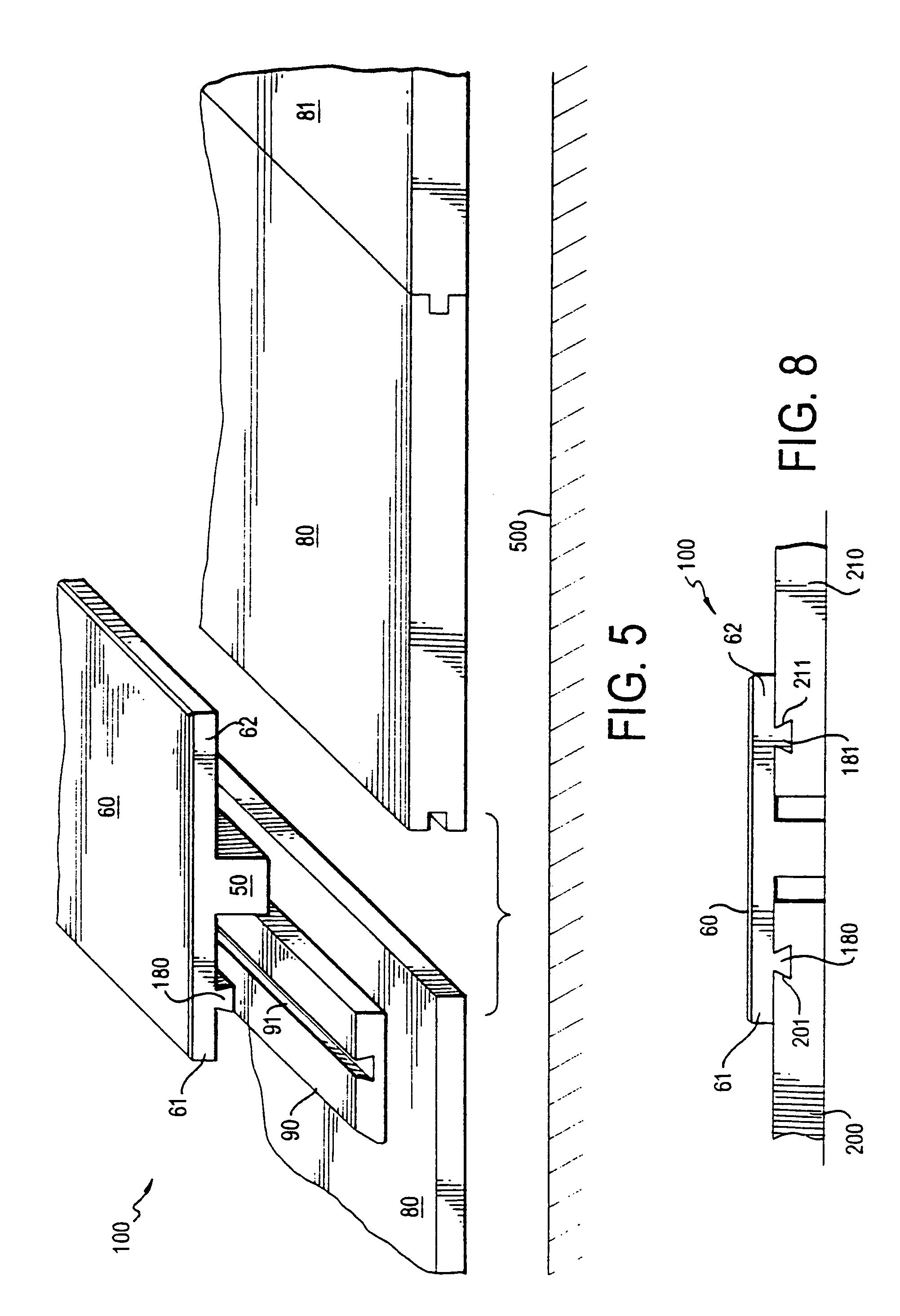

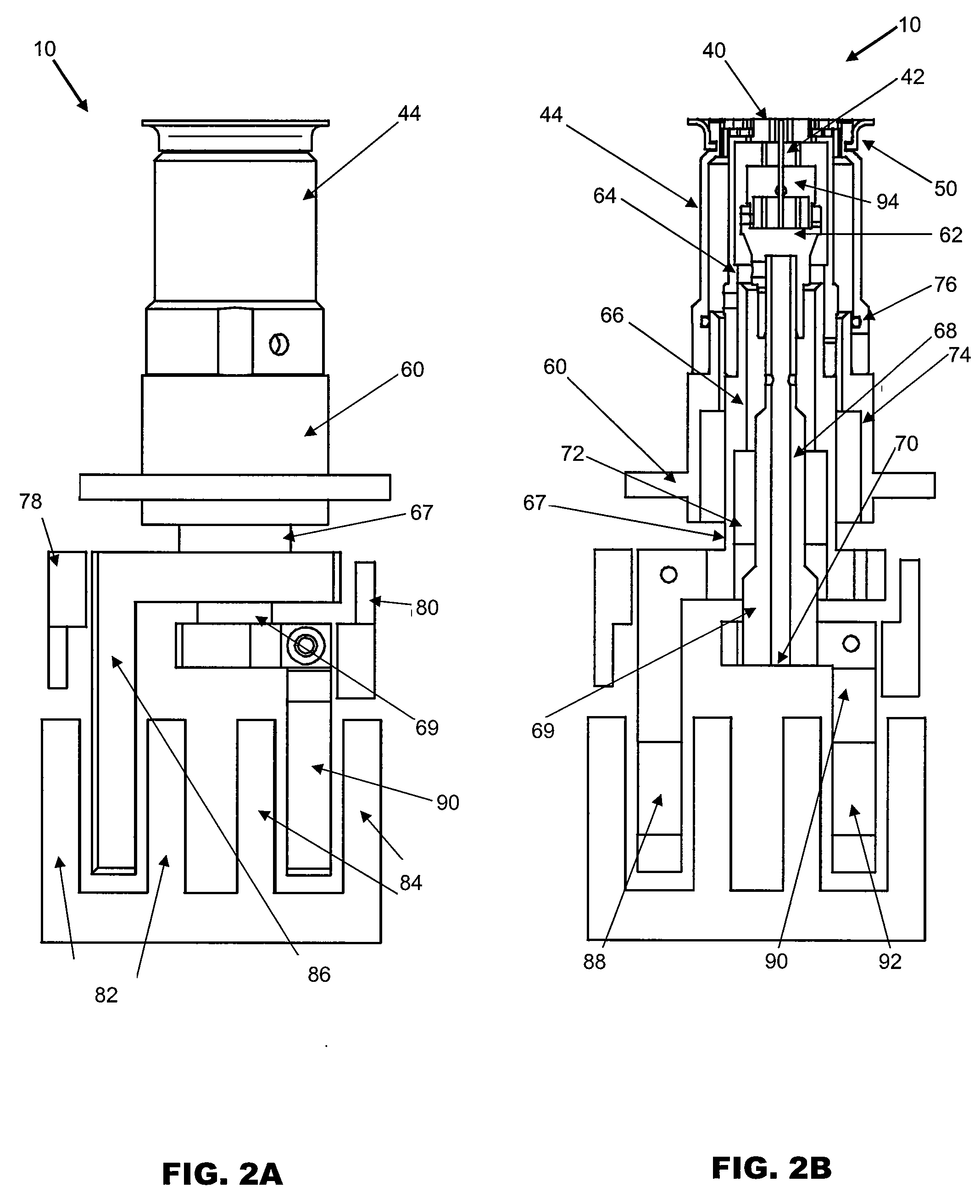

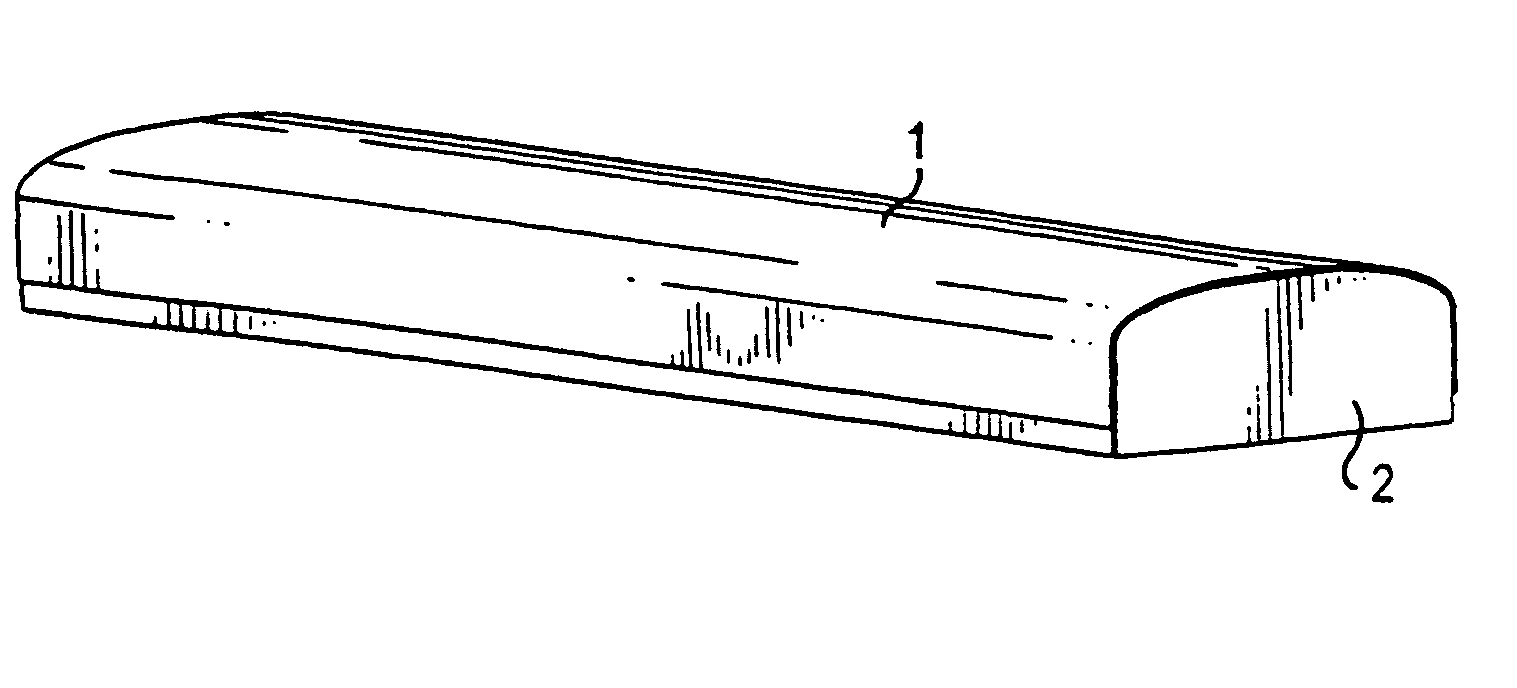

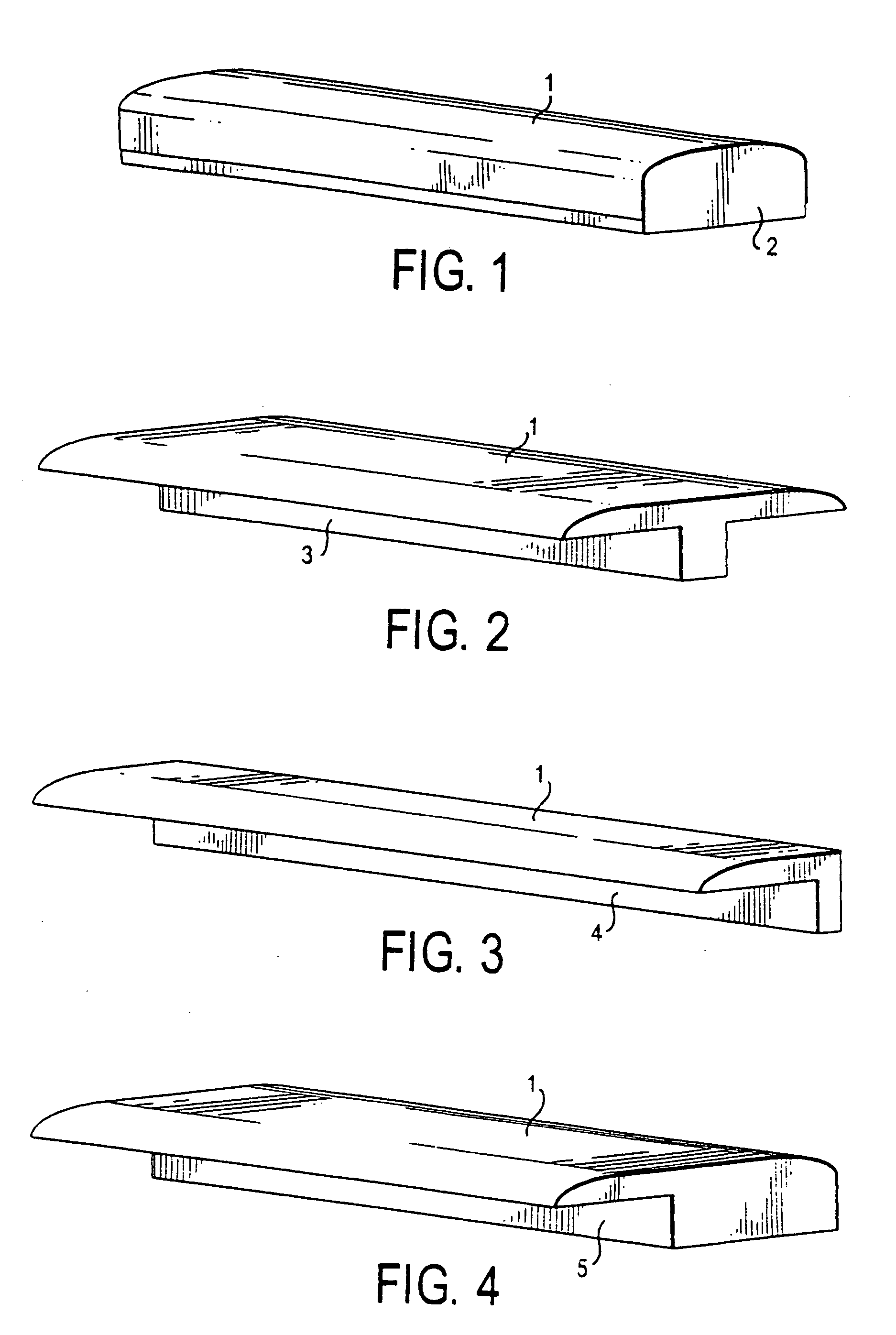

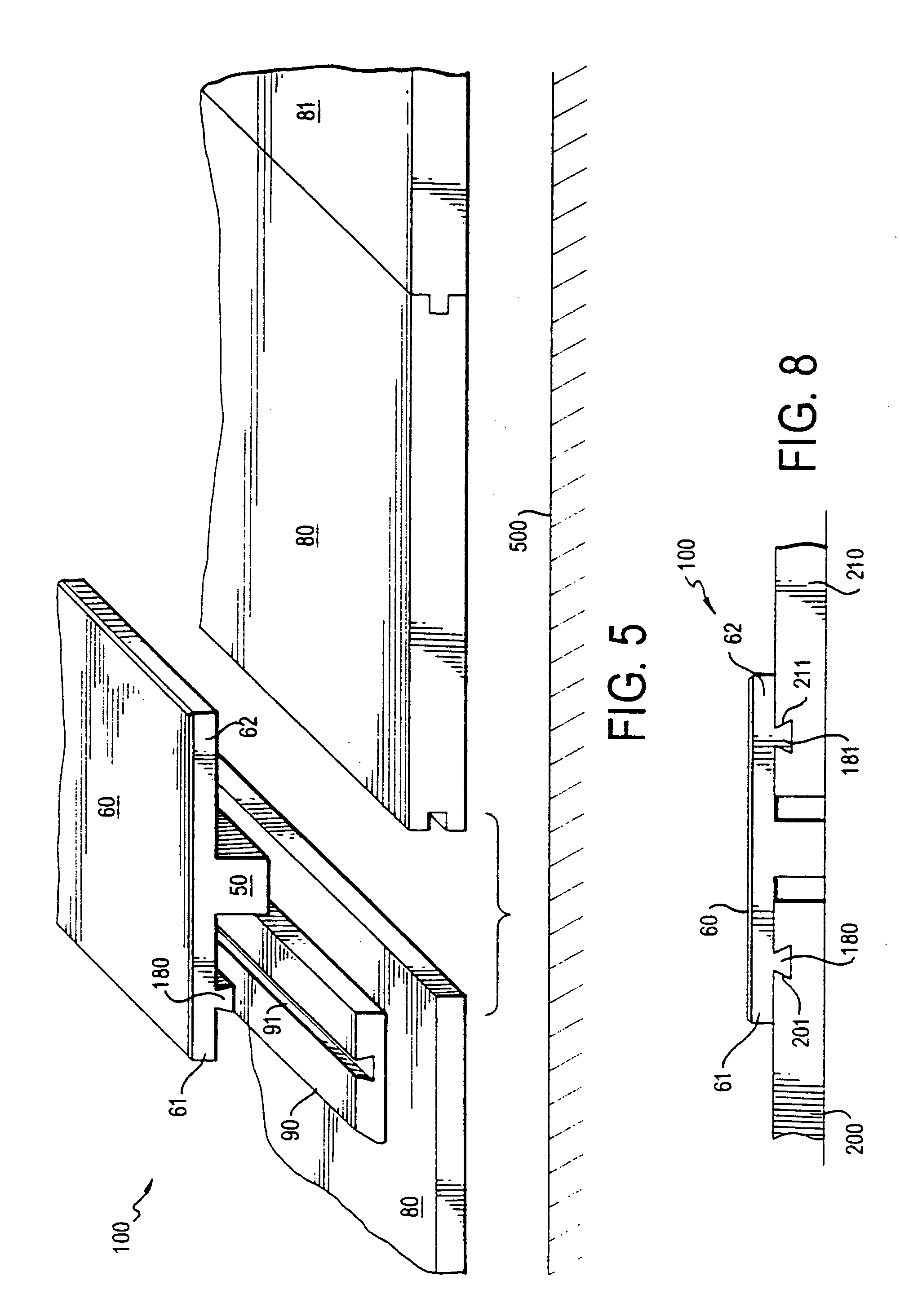

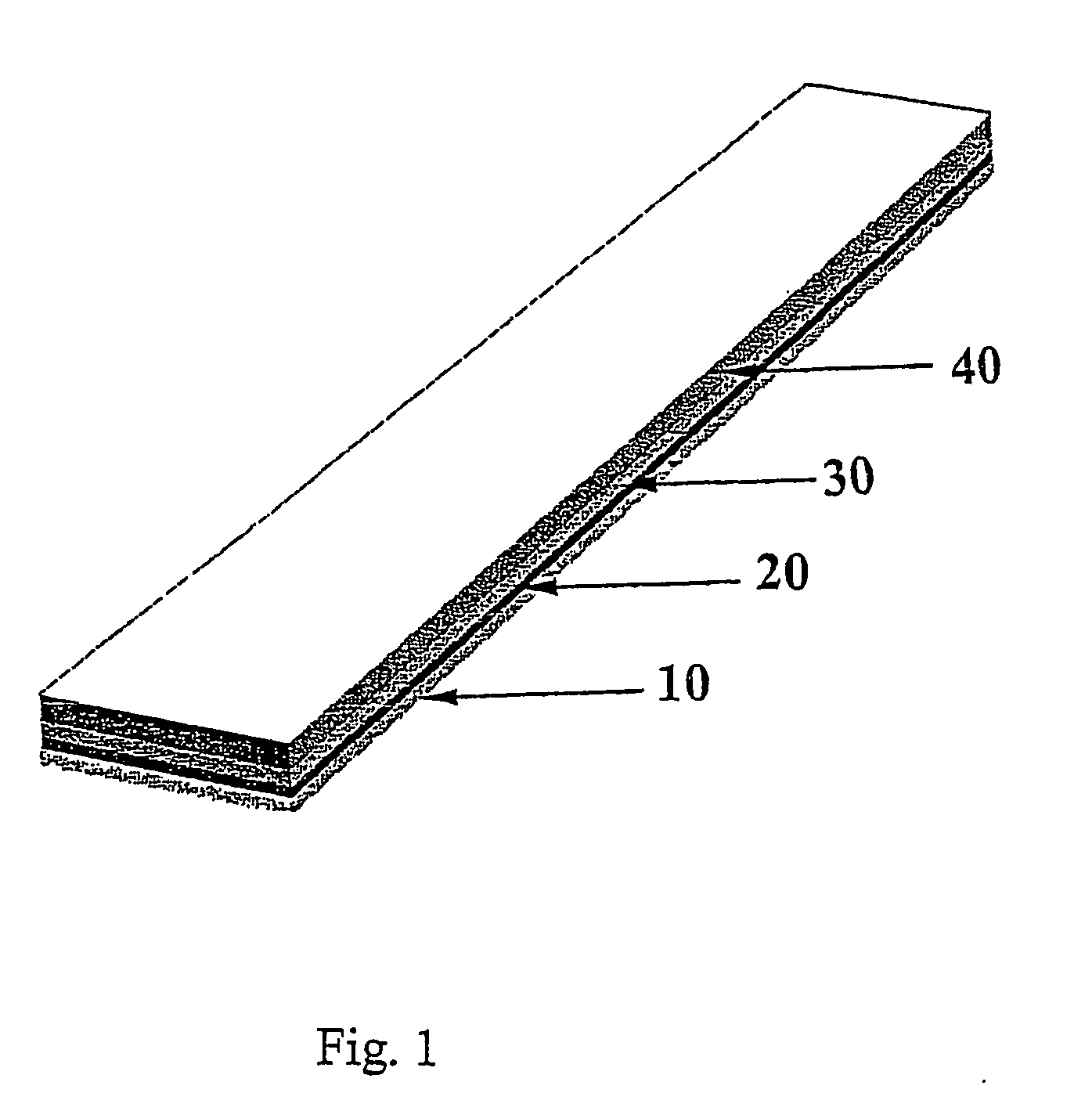

Floor strip

InactiveUS6898911B2Increase resistanceSmooth transitionWood working apparatusPaper/cardboardReducerEngineering

Owner:PERGO

Floor strip

InactiveUS20050003149A1Increase resistanceSmooth transitionWood working apparatusCeramic shaping apparatusEngineeringReducer

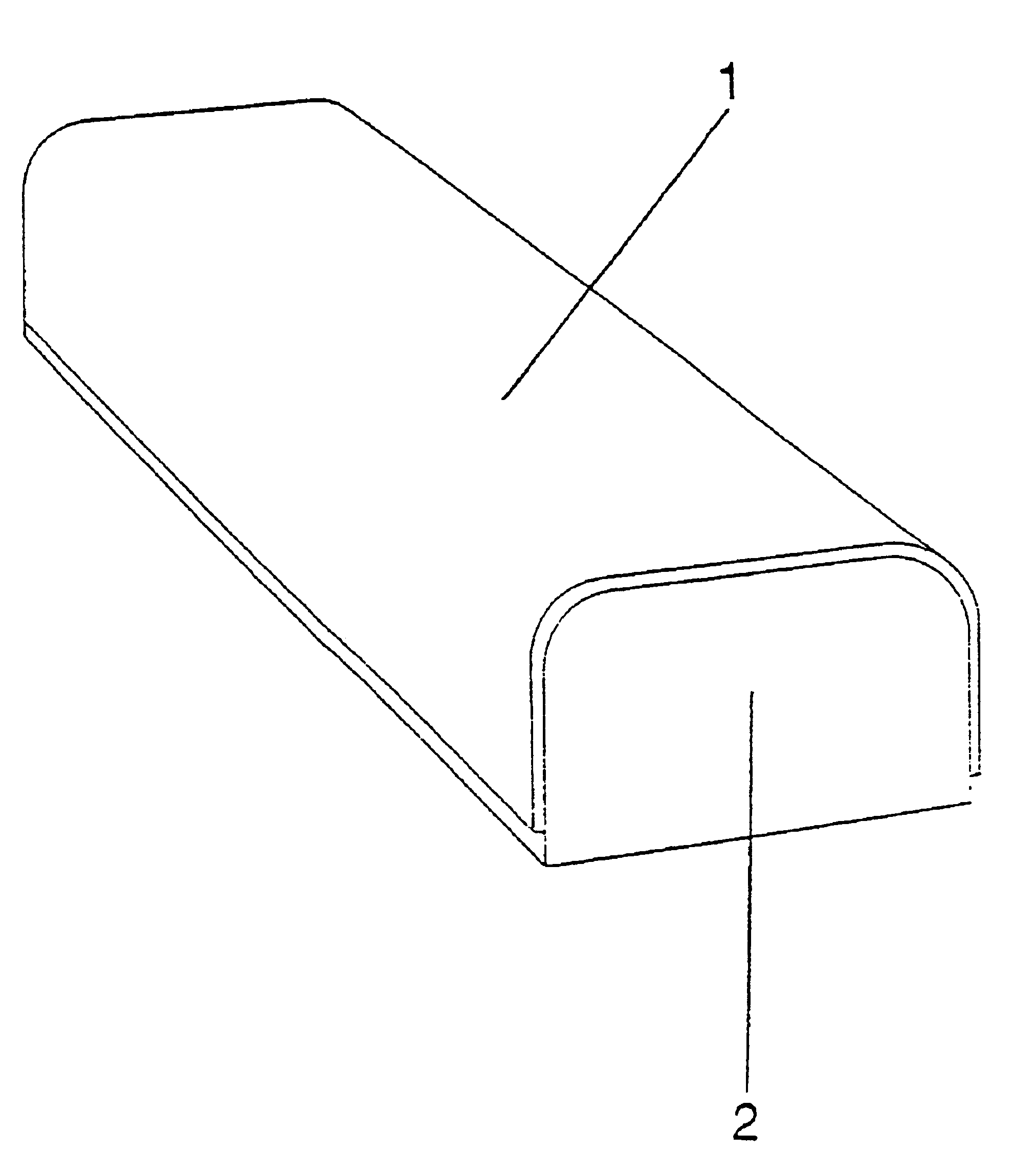

A thin decorative thermosetting laminate of postforming quality is glued to a longitudinal carrier to form a floor strip. The laminate has a thermosetting resin as well as hard particles impregnated therein to increase the abrasion resistance of the laminate. The carrier generally has a cross section of a dilatation, transition or a finishing profile, depending on the intended use of the floor strip. The floor strip has a tab portion on a surface that engages a channel on a floor tile or a reducer. The tab portion locks the floor strip into place and prevents movement of the floor tile or the reducer with respect to the floor strip.

Owner:PERGO

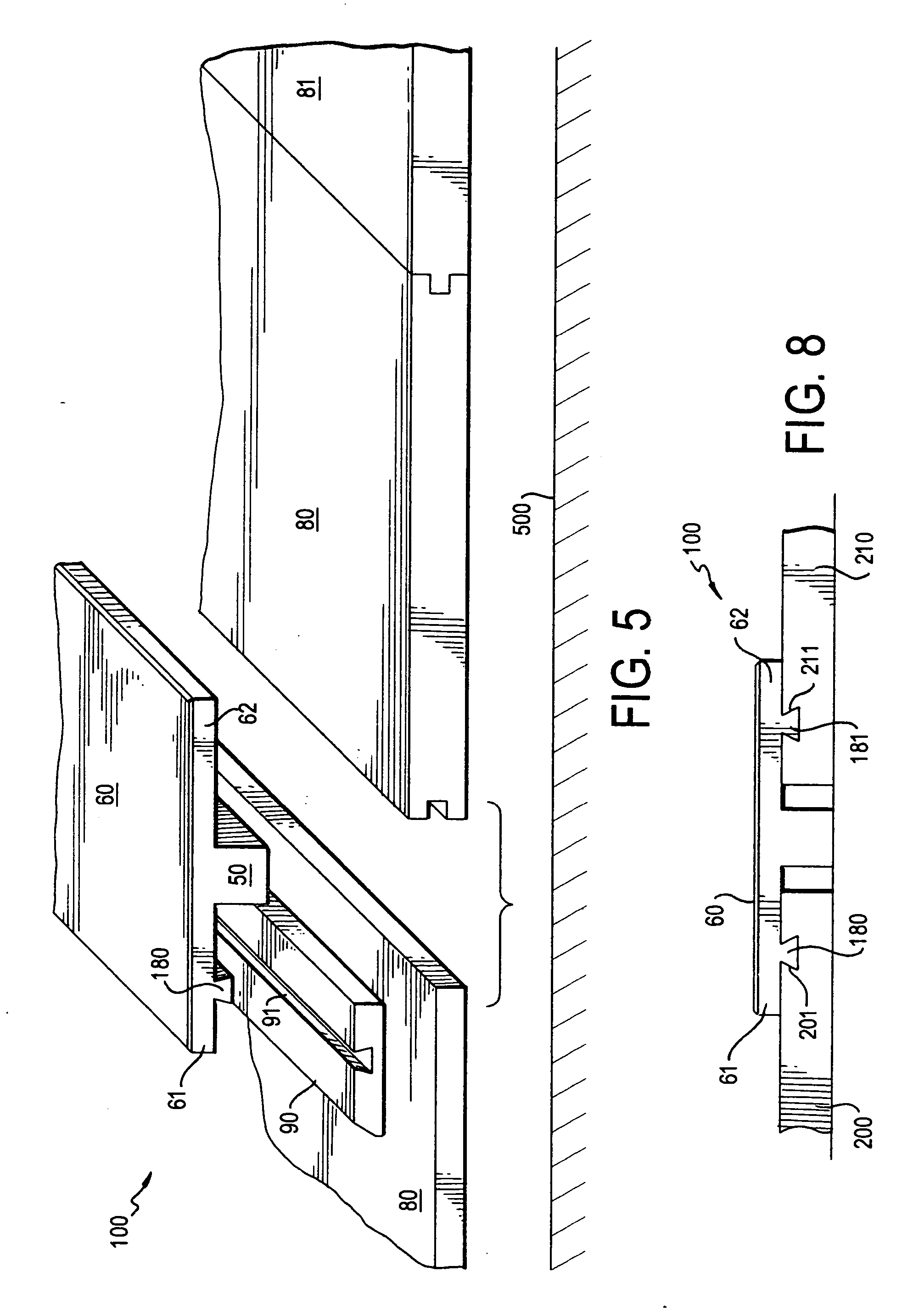

Method and apparatus for manufacturing microfibrillated cellulose fiber

ActiveUS20050194477A1Efficient and stable productionQuality improvementNon-fibrous pulp additionNatural cellulose pulp/paperCellulose fiberSlurry

A method for producing a microfibrillated cellulose, which comprises subjecting a slurry containing a pulp having a solids concentration of 1 to 6 wt % to the treatment with a disc refiner repeatedly ten times or more, to thereby prepare a microfibrillated cellulose having a number average fiber length or 0.2 mm or less and an amount of water hold of 10 mL / g or more, the amount representing the volume of water capable of being held by a unit weight of the cellulose fiber. The method allows the production of a microfibrillated cellulose having high quality with stability and with good efficiency.

Owner:DSG INT LTD

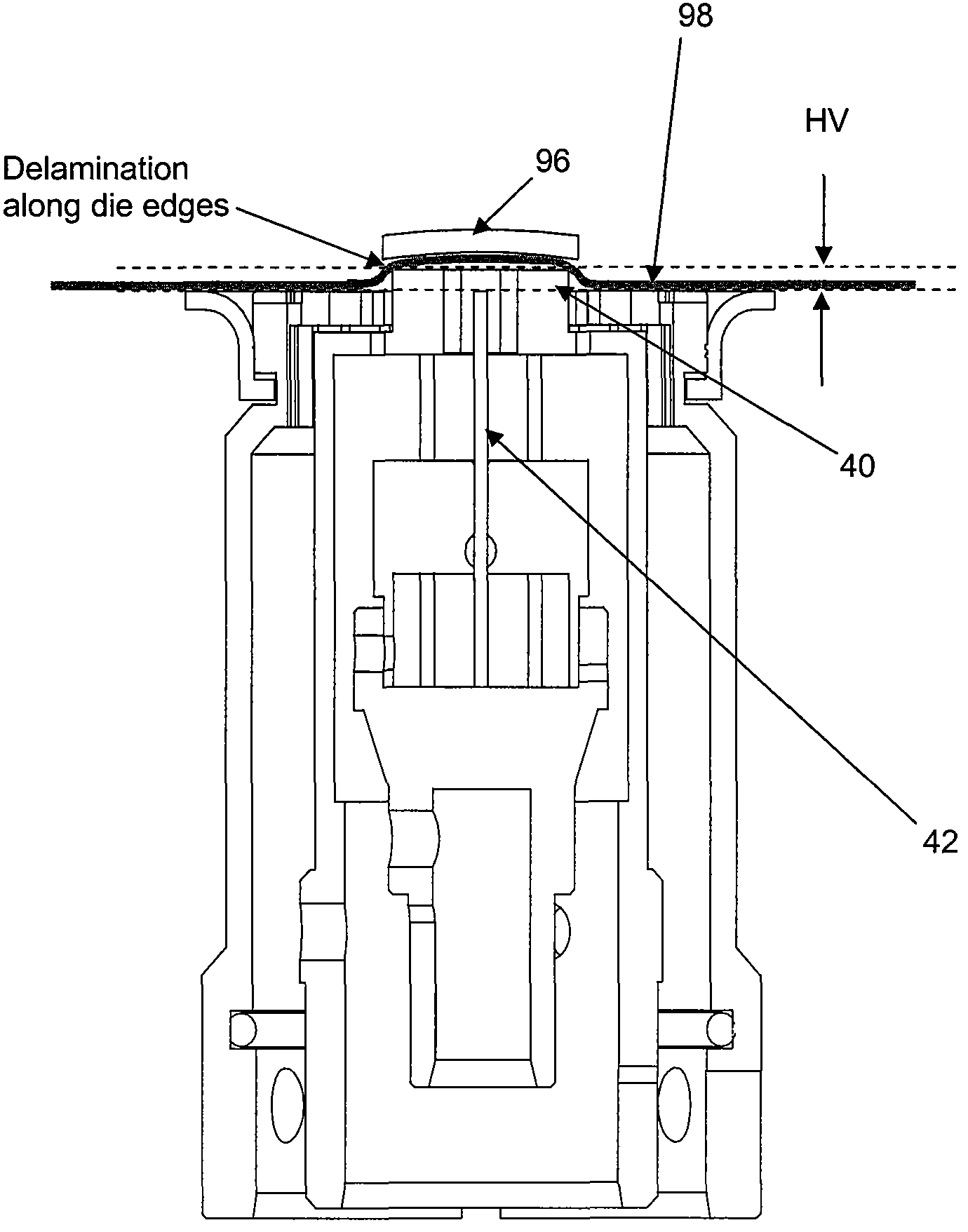

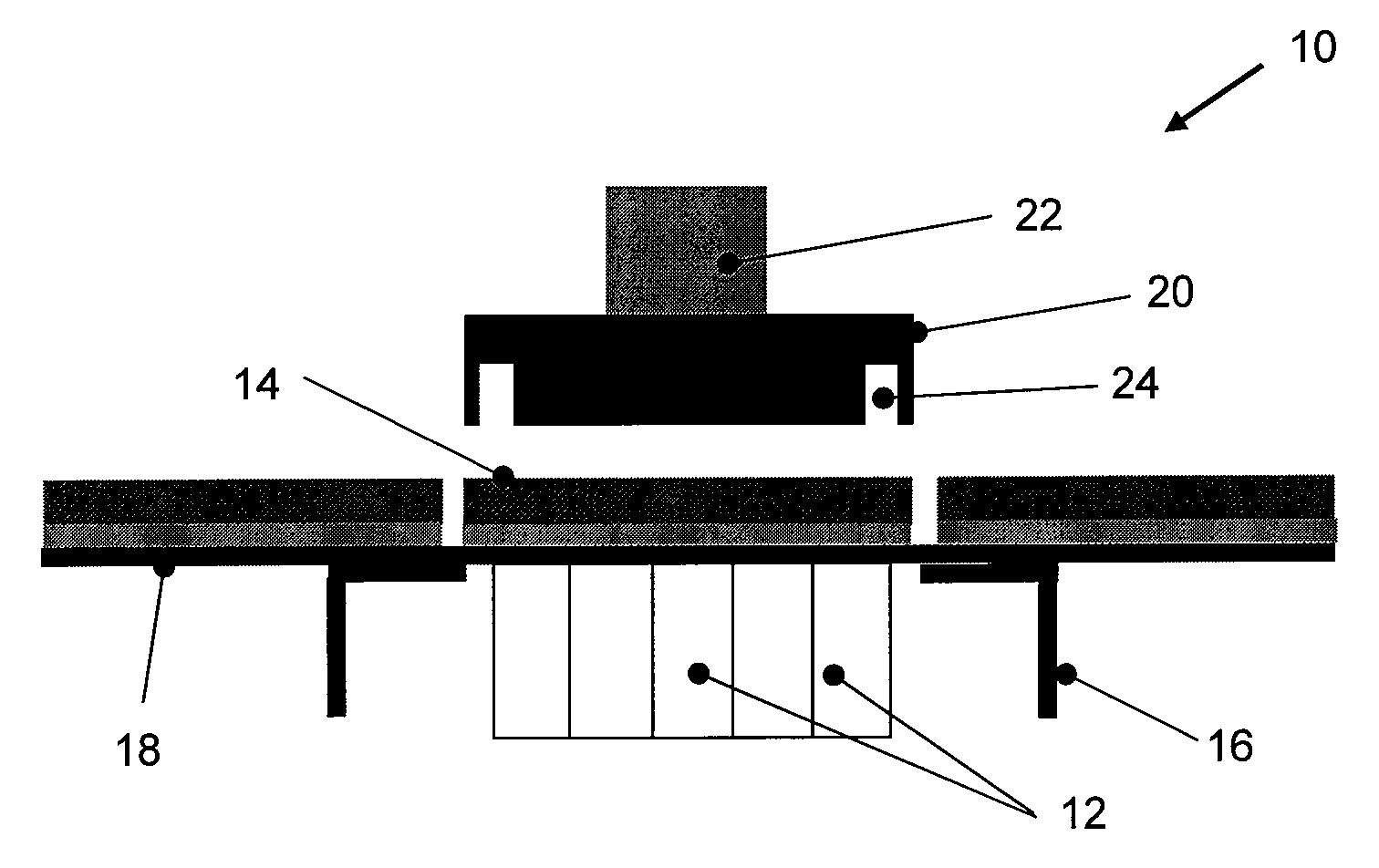

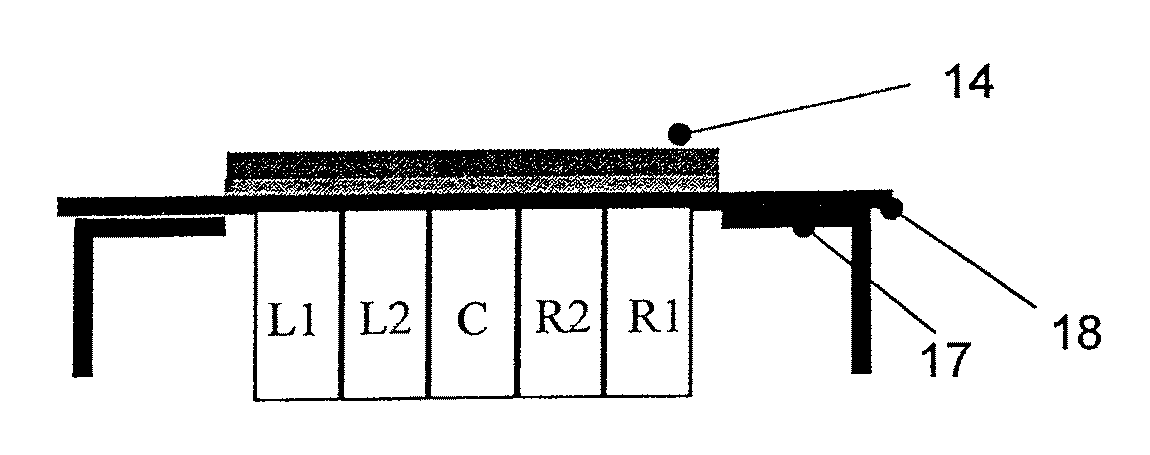

Vibration-induced die detachment system

ActiveUS7757742B2Reduced risk of cracking and deformationLamination ancillary operationsSlide fastenersEngineeringMechanical engineering

A die is detachable from an adhesive tape on which the die is mounted with a die detachment tool comprising a vacuum enclosure that is operative to provide a vacuum suction on the adhesive tape. One or more ejector pins are housed in the vacuum enclosure and are projectable from the vacuum enclosure for lifting the die and adhesive tape. A vibrational tool is housed in the vacuum enclosure adjacent to the ejector pins and it is projectable from the vacuum enclosure to contact a portion of the adhesive tape at which the die is located. The vibrational tool is further operative to oscillate the adhesive tape and die for promoting delamination of the die from the adhesive tape.

Owner:ASM ASSEMBLY AUTOMATION LTD

Floor strip

A thin decorative thermosetting laminate of postforming quality is glued to a longitudinal carrier to form a floor strip. The laminate has a thermosetting resin as well as hard particles impregnated therein to increase the abrasion resistance of the laminate. The carrier generally has a cross section of a dilatation, transition or a finishing profile, depending on the intended use of the floor strip. The floor strip has a tab portion on a surface that engages a channel on a floor tile or a reducer. The tab portion locks the floor strip into place and prevents movement of the floor tile or the reducer with respect to the floor strip.

Owner:PERGO

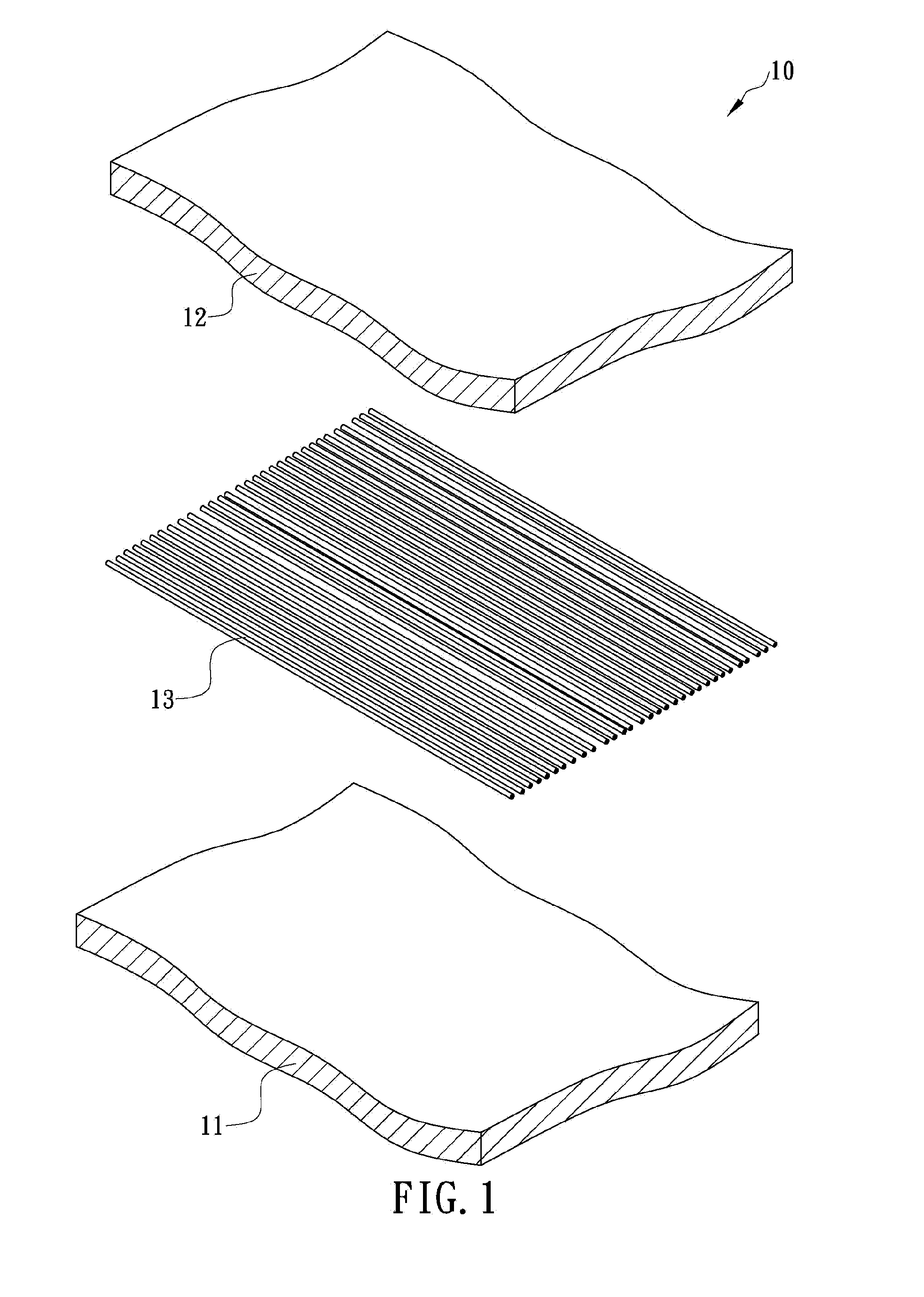

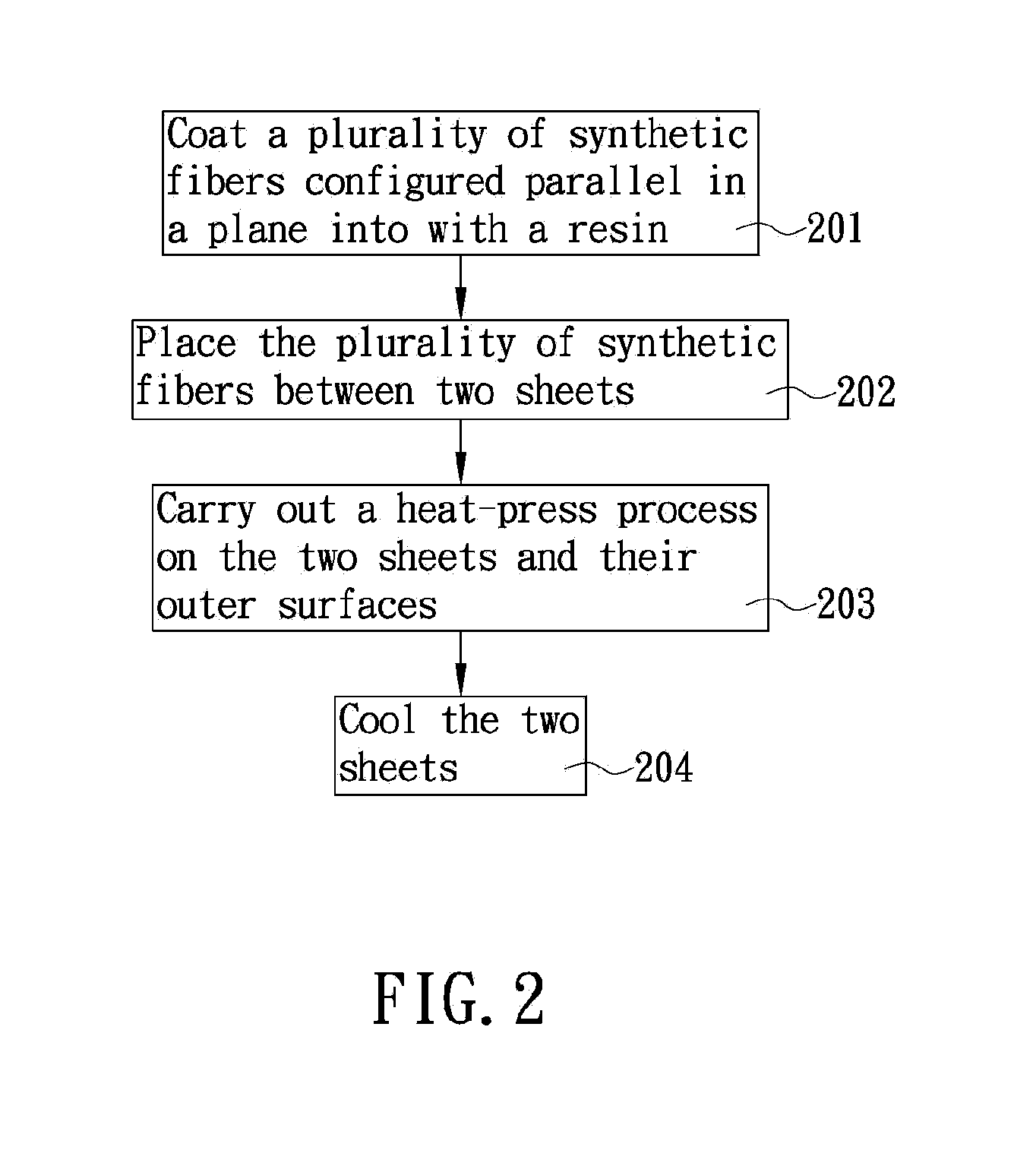

Emulated wood with pores and fibers and fabrication method thereof

ActiveUS20150376840A1Reduce surface polarityImprove compatibilityNatural cellulose pulp/paperPaper after-treatmentPolymer scienceFoaming agent

A method for fabricating emulated wood with pores and fibers, comprising: immersing a plurality of synthetic fibers configured parallel in a plane into a resin so that the resin is coated on the surfaces of the plurality of synthetic fibers and in the gaps between the plurality of synthetic fibers; placing the plurality of synthetic fibers between two sheets, wherein the two sheets are planar sheets made from a uniform composition comprising a thermoplastic elastomer, a foaming agent, and a crosslinking agent; carrying out a heat-press process on the two sheets so that the foaming agent undergoes microcellular foaming and forms dense closed pores in the two sheets, and so that the composition on inner surfaces of the two sheets expands towards the plurality of synthetic fibers and penetrates through the gaps between the plurality of synthetic fibers; and cooling the two sheets to yield an emulated wood board.

Owner:MICROCELL COMPOSITE CO LTD

Application of methylenediphenyldiisocyanate for producing gypsum/wood fiber board

InactiveUS7056460B2Uniformly good strengthProduced at practical costFibreboardNon-fibrous pulp additionEmulsionSulfate

A process for making an improved gypsum / wood fiber board is described. Products resulting from the process are also described. The process comprises adding a diisocyanate, specifically methylenediphenyldiisocyanate (MDI) to an aqueous slurry of calcium sulfate material and cellulosic fibers, where the MDI is added as an emulsion stable in the conditions in which the slurry is maintained. The process further includes passing the MDI containing slurry onto a flat porous forming surface to form a filter cake; removing a substantial portion of the water from the filter cake through the porous surface; pressing the filter cake to form a board and remove additional water; and drying the board to remove the remaining free water.

Owner:UNITED STATES GYPSUM CO

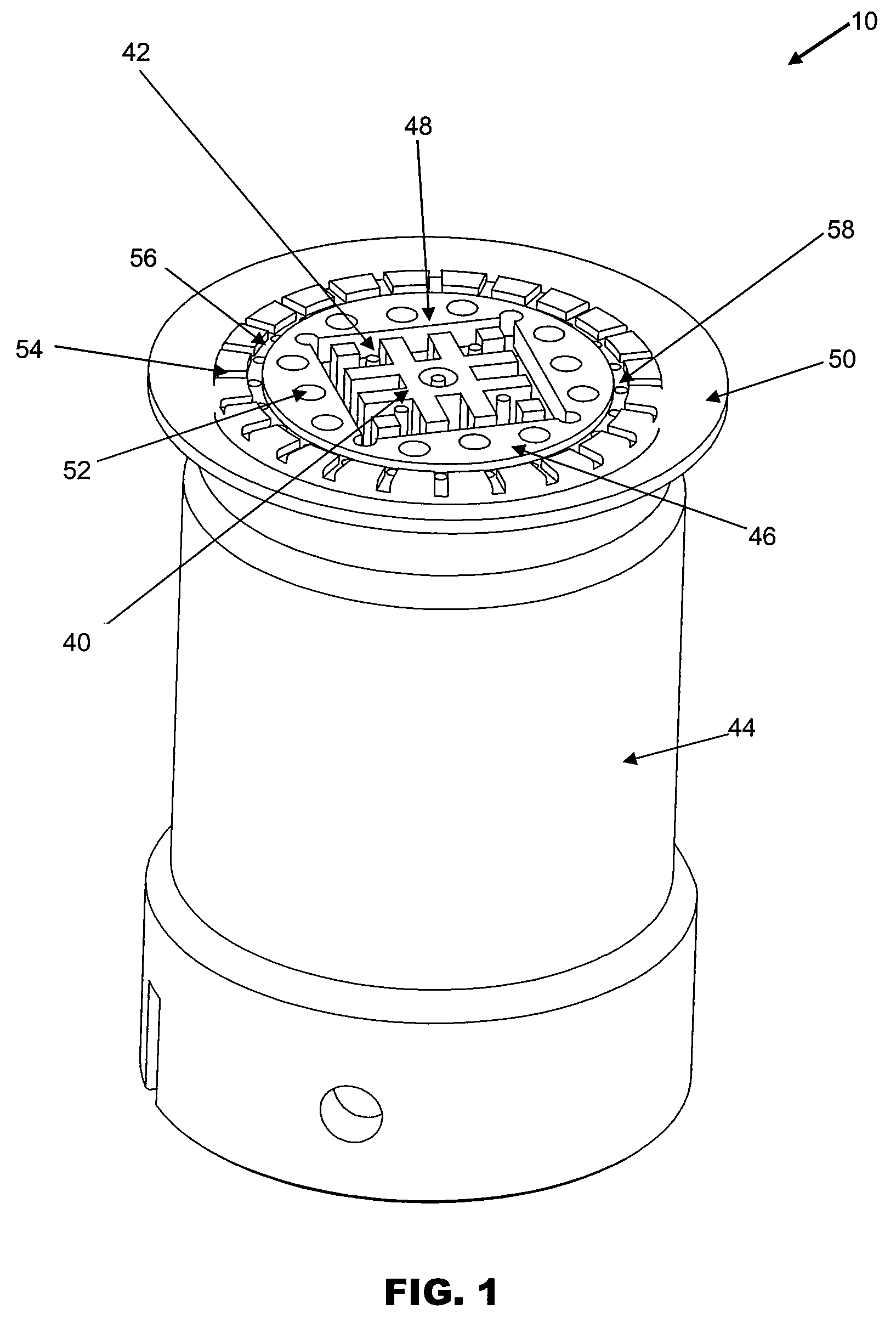

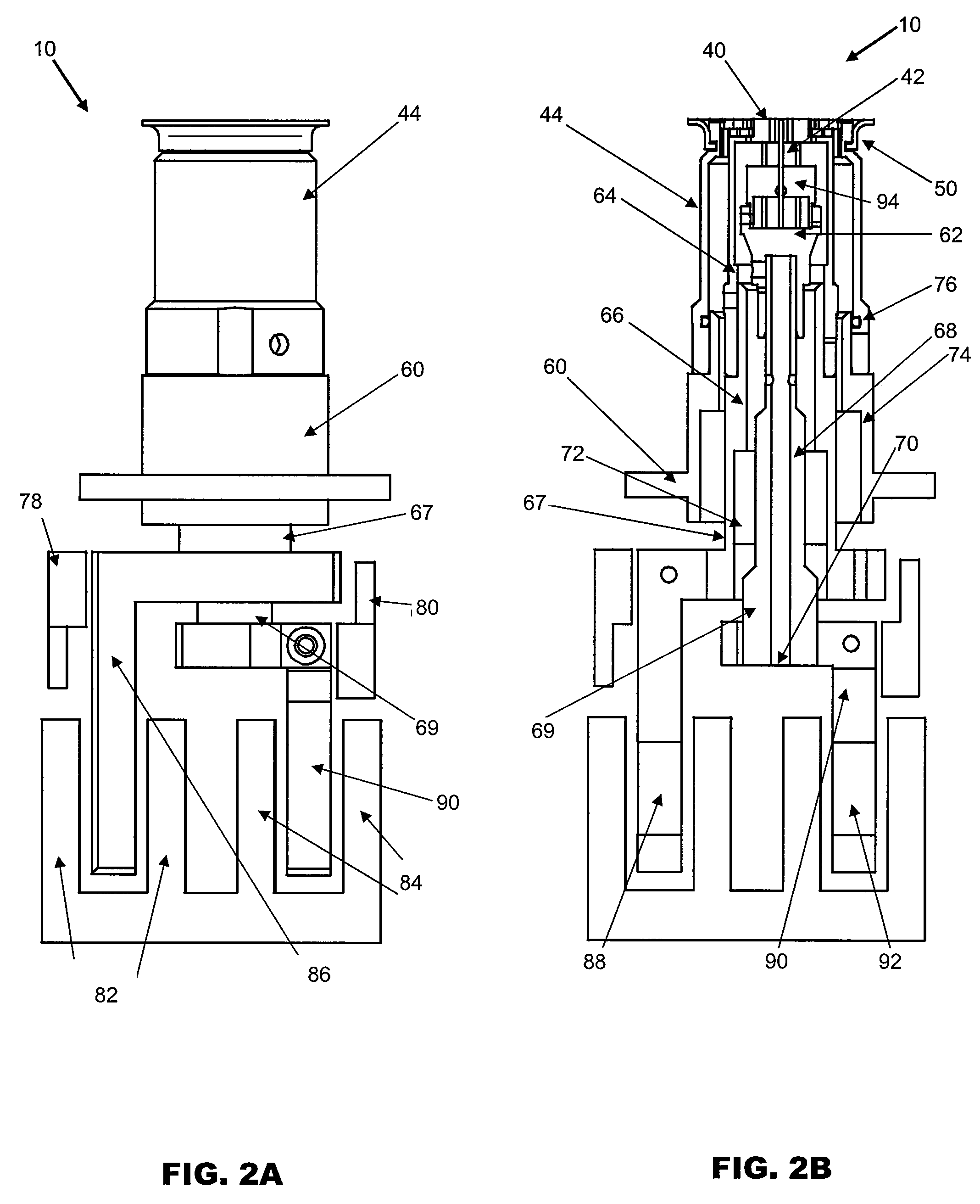

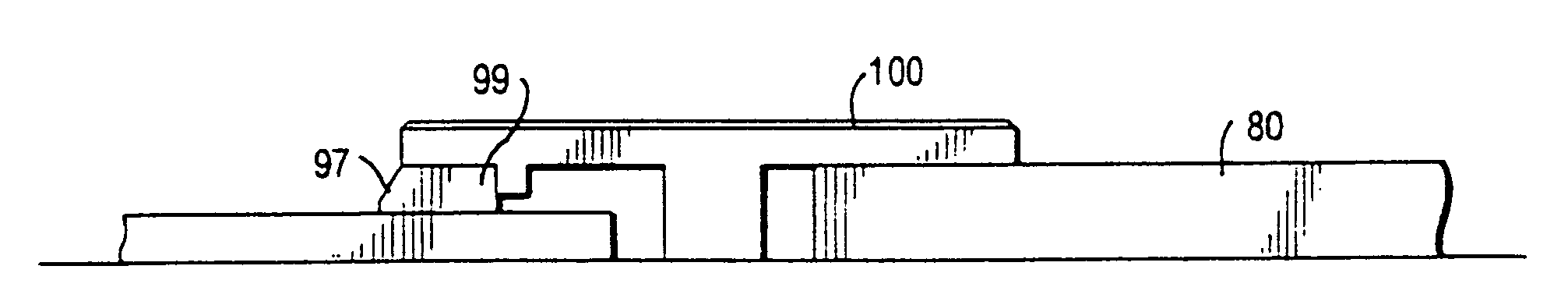

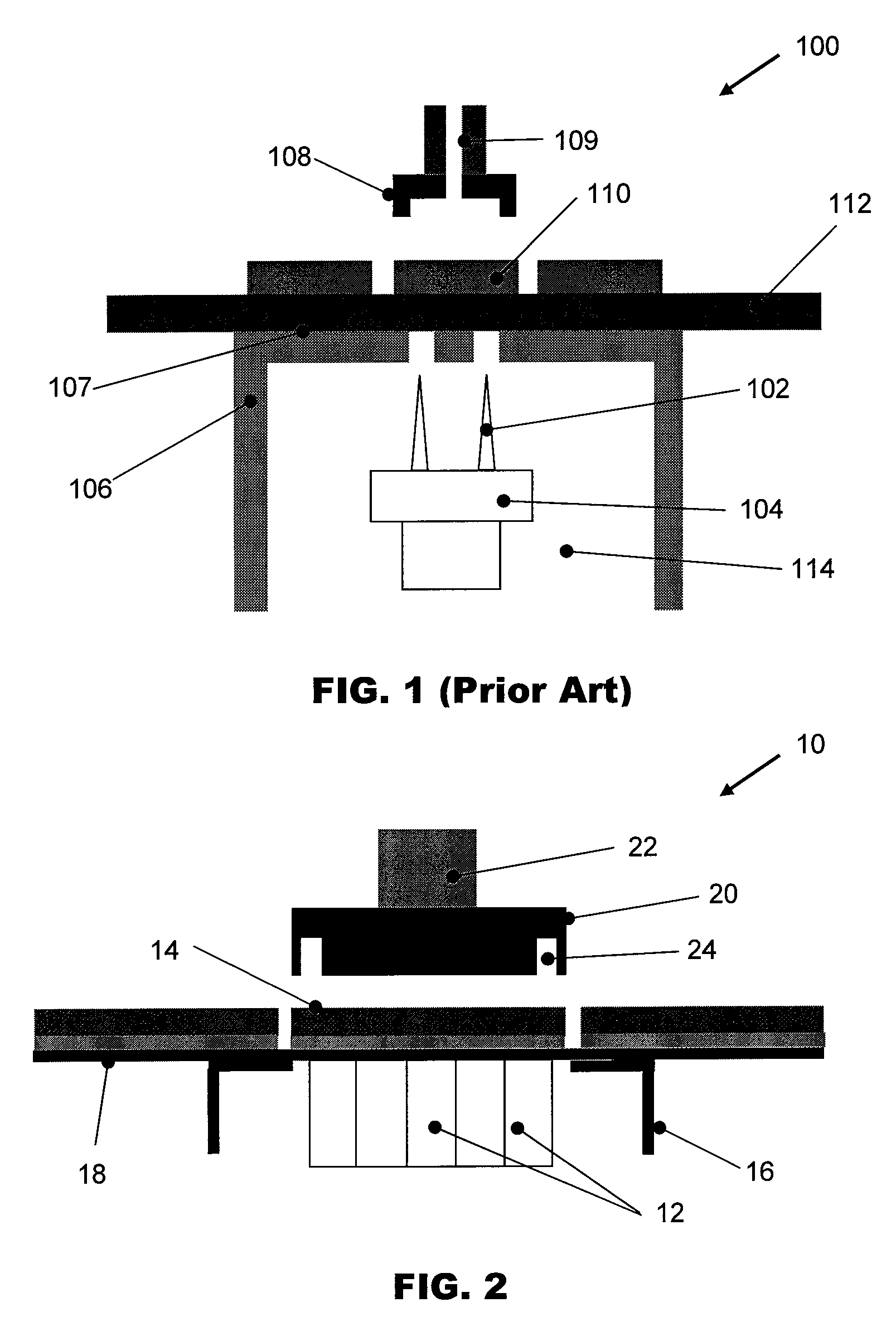

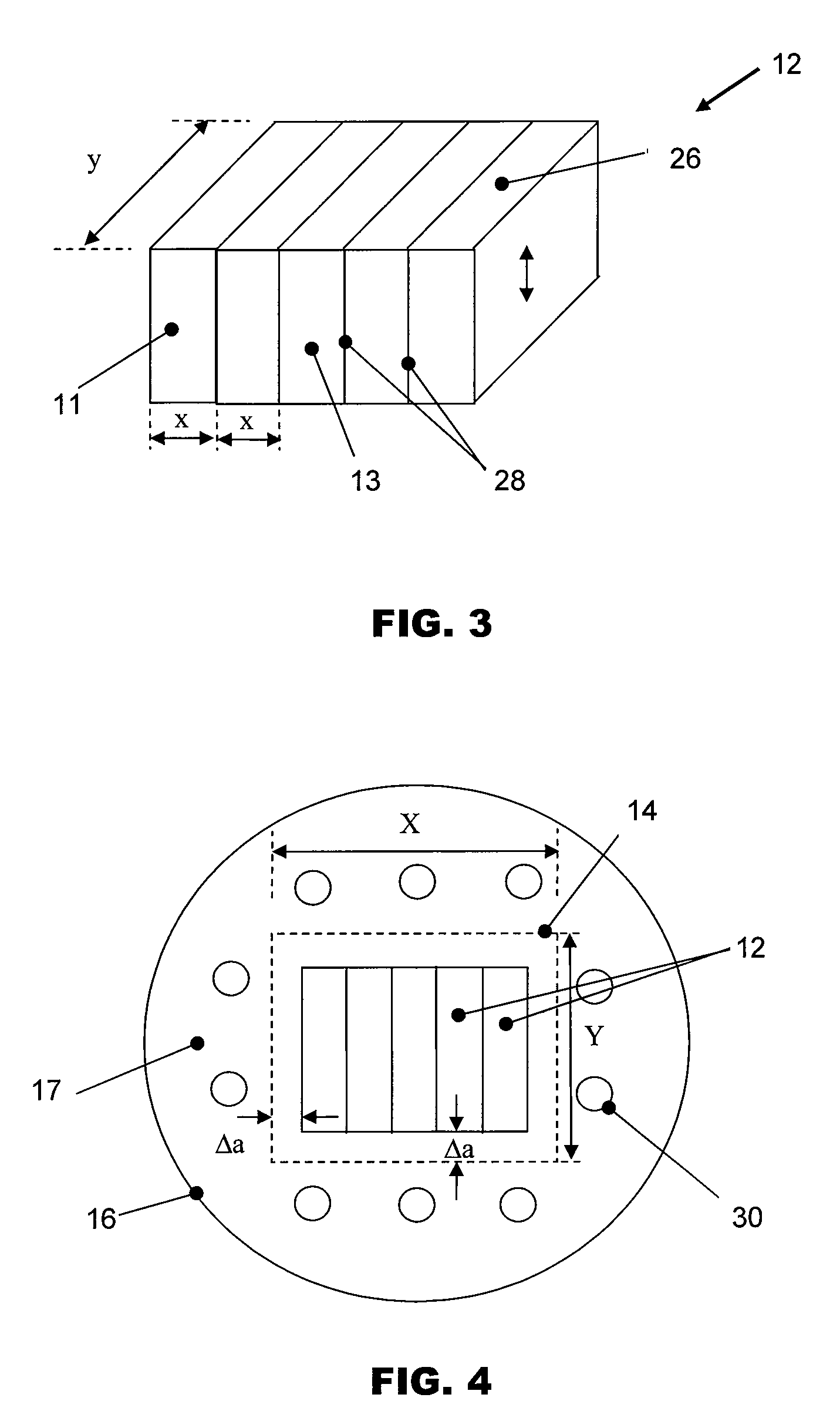

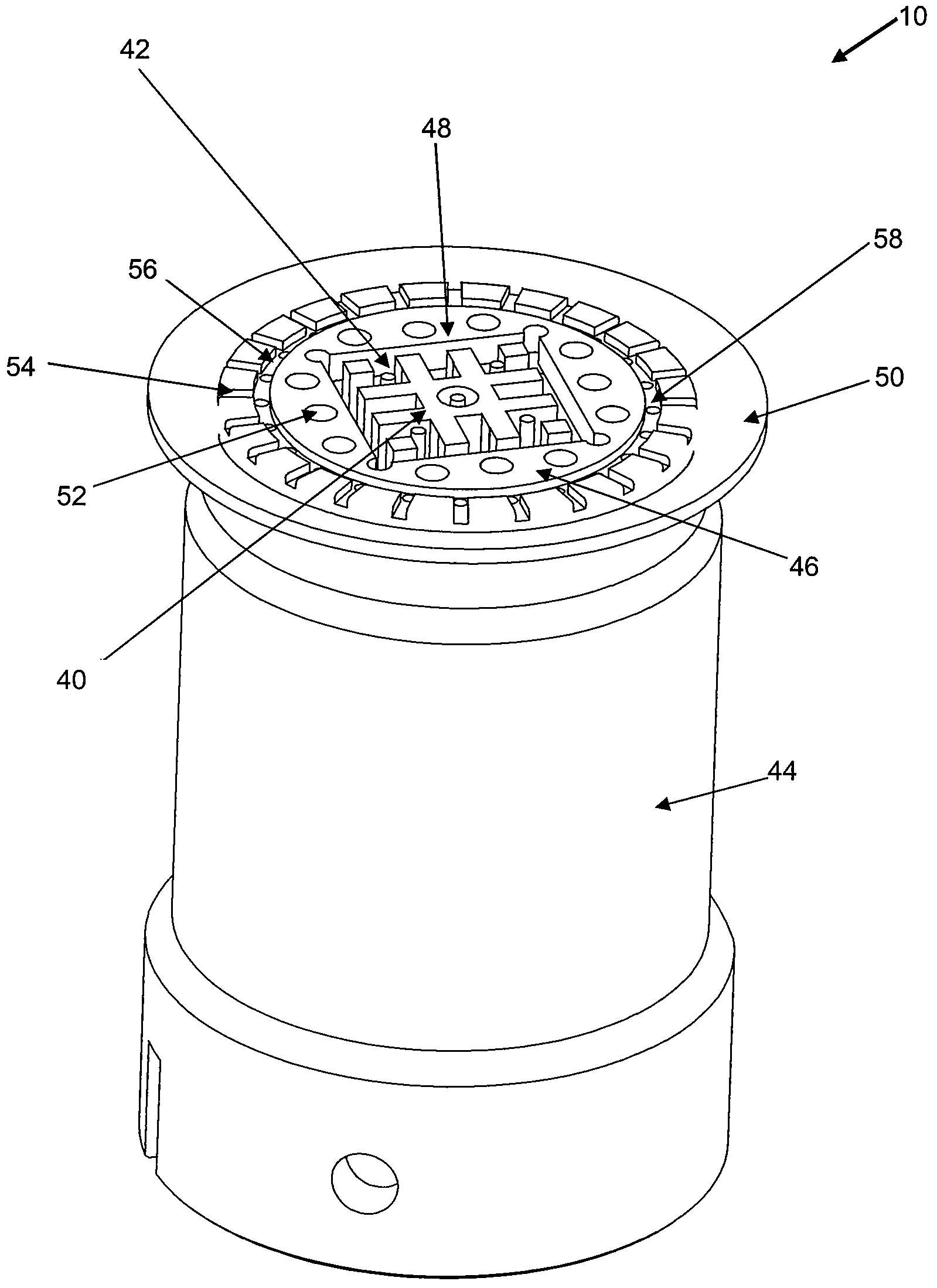

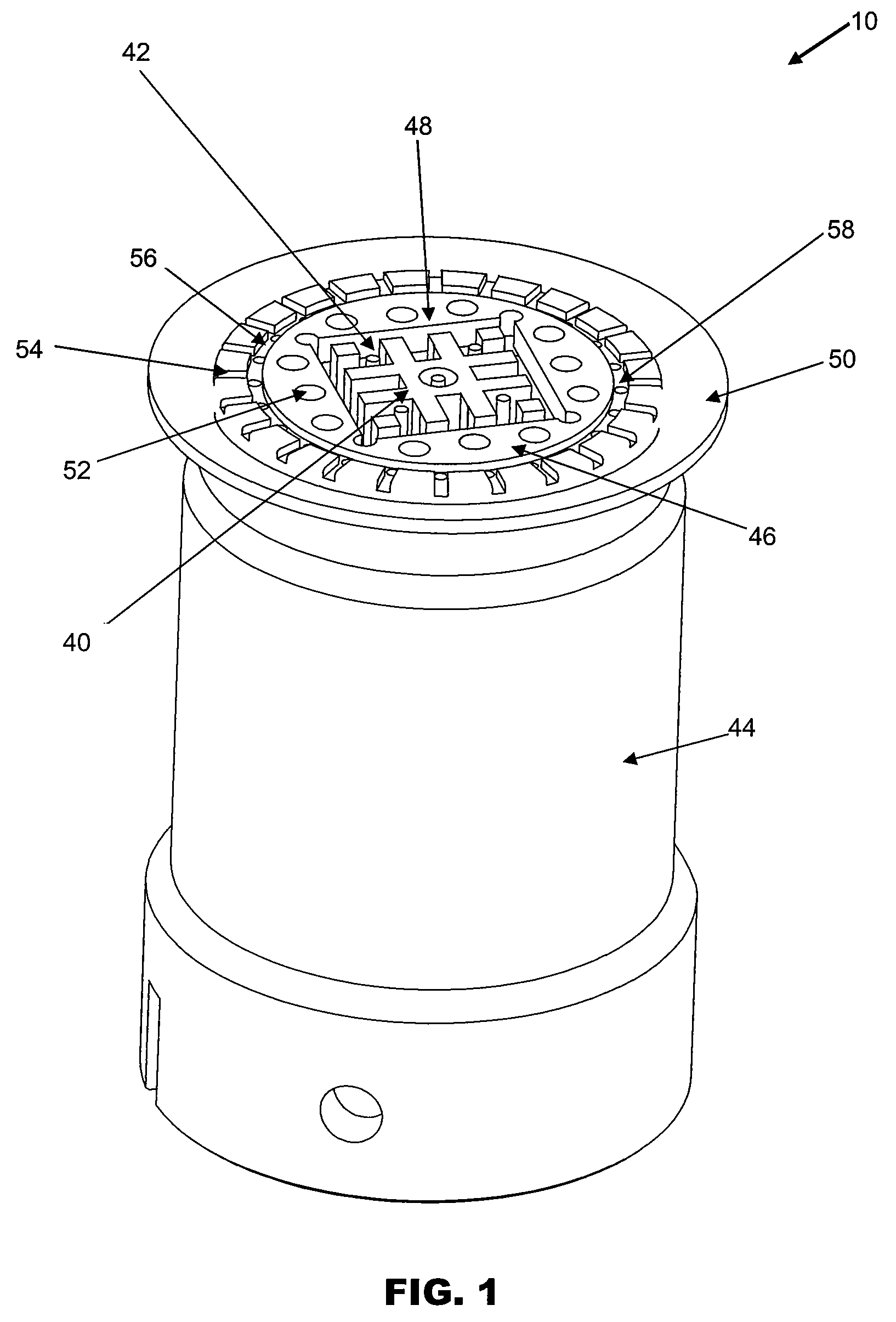

Device for thin die detachment and pick-up

ActiveUS20100252205A1Relieve pressureSlide fastenersSolid-state devicesEngineeringMechanical engineering

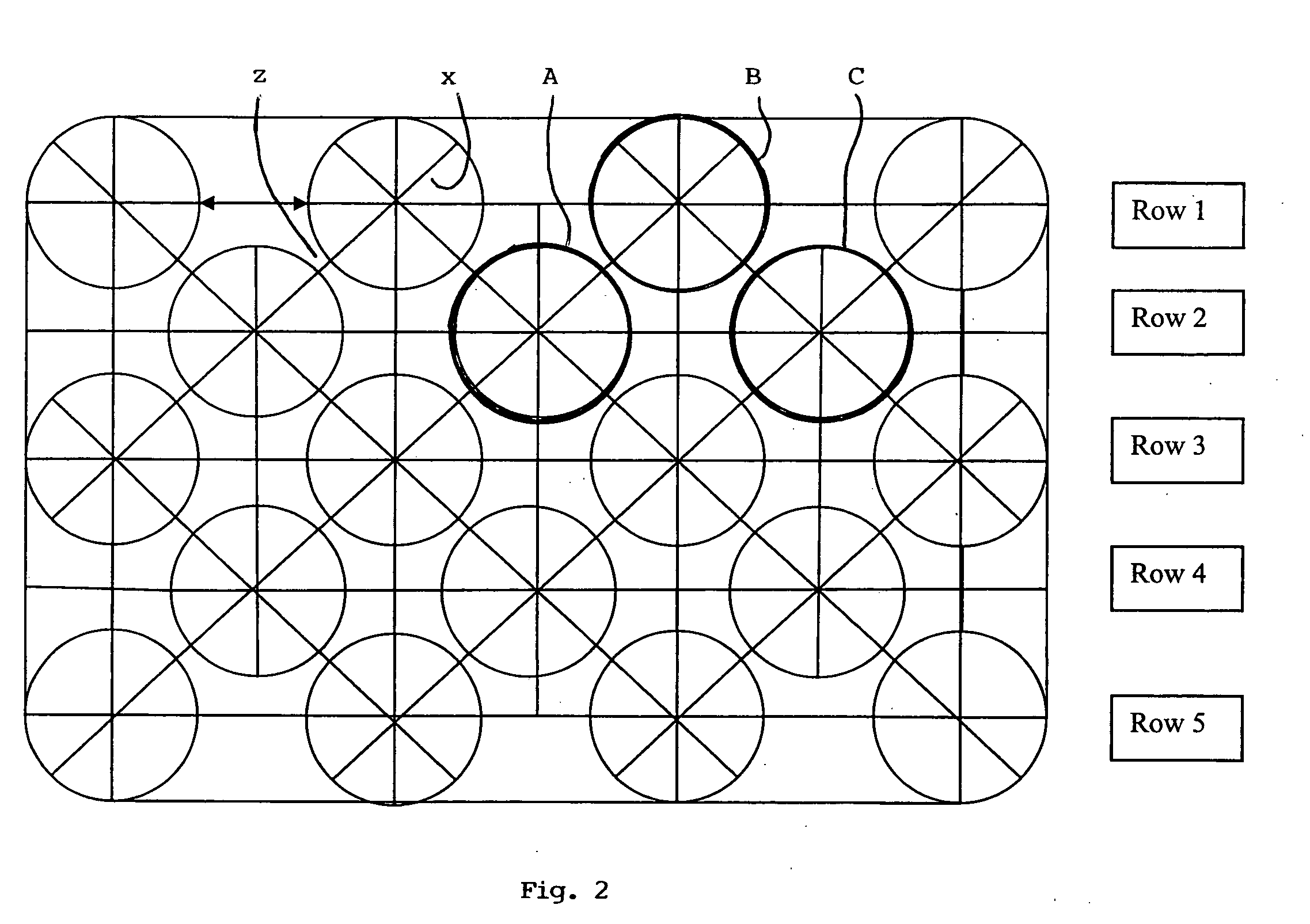

A die detachment device for delaminating a die which is mounted at a position on an adhesive film comprises a plurality of movable plates having quadrilateral-shaped contact surfaces which are arranged adjacent to one another. The plurality of movable plates comprises an intermediate movable plate and outer movable plates on opposite sides of the intermediate movable plate. The contact surfaces of the movable plates together form a combined contact surface for supporting the adhesive film at the position of the die, each movable plate being movable relative to the other movable plates towards and away from the die.

Owner:ASM ASSEMBLY AUTOMATION LTD

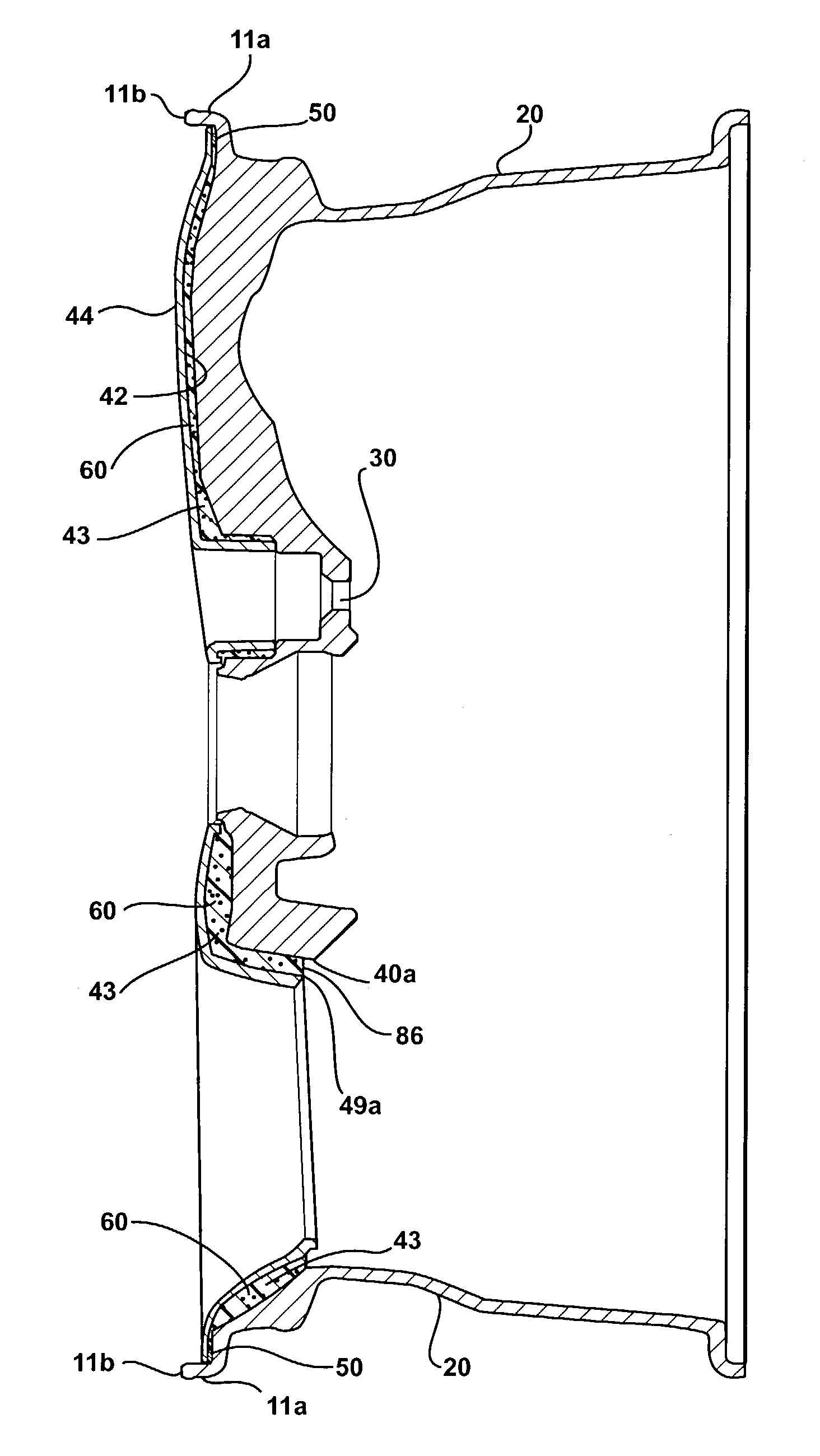

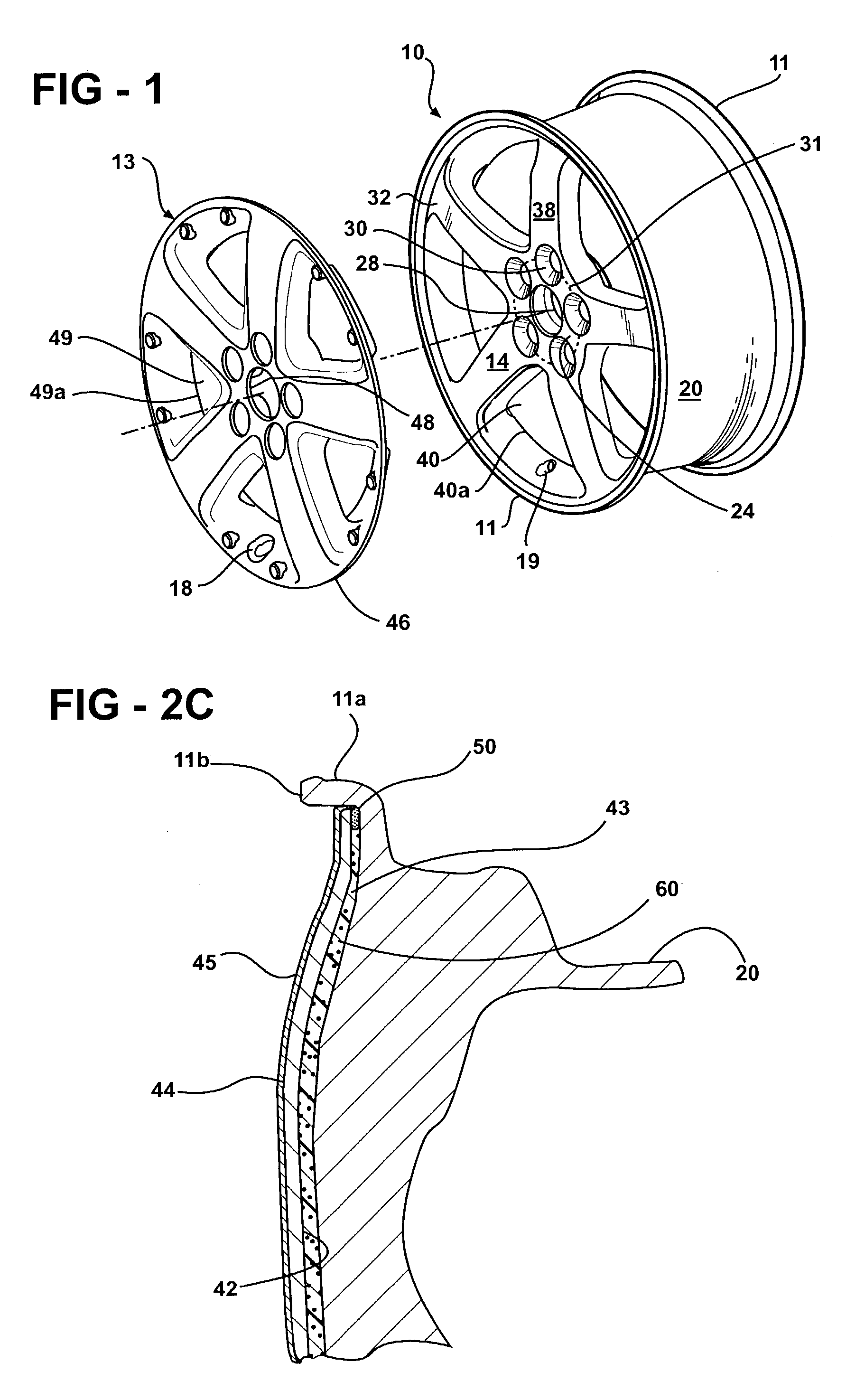

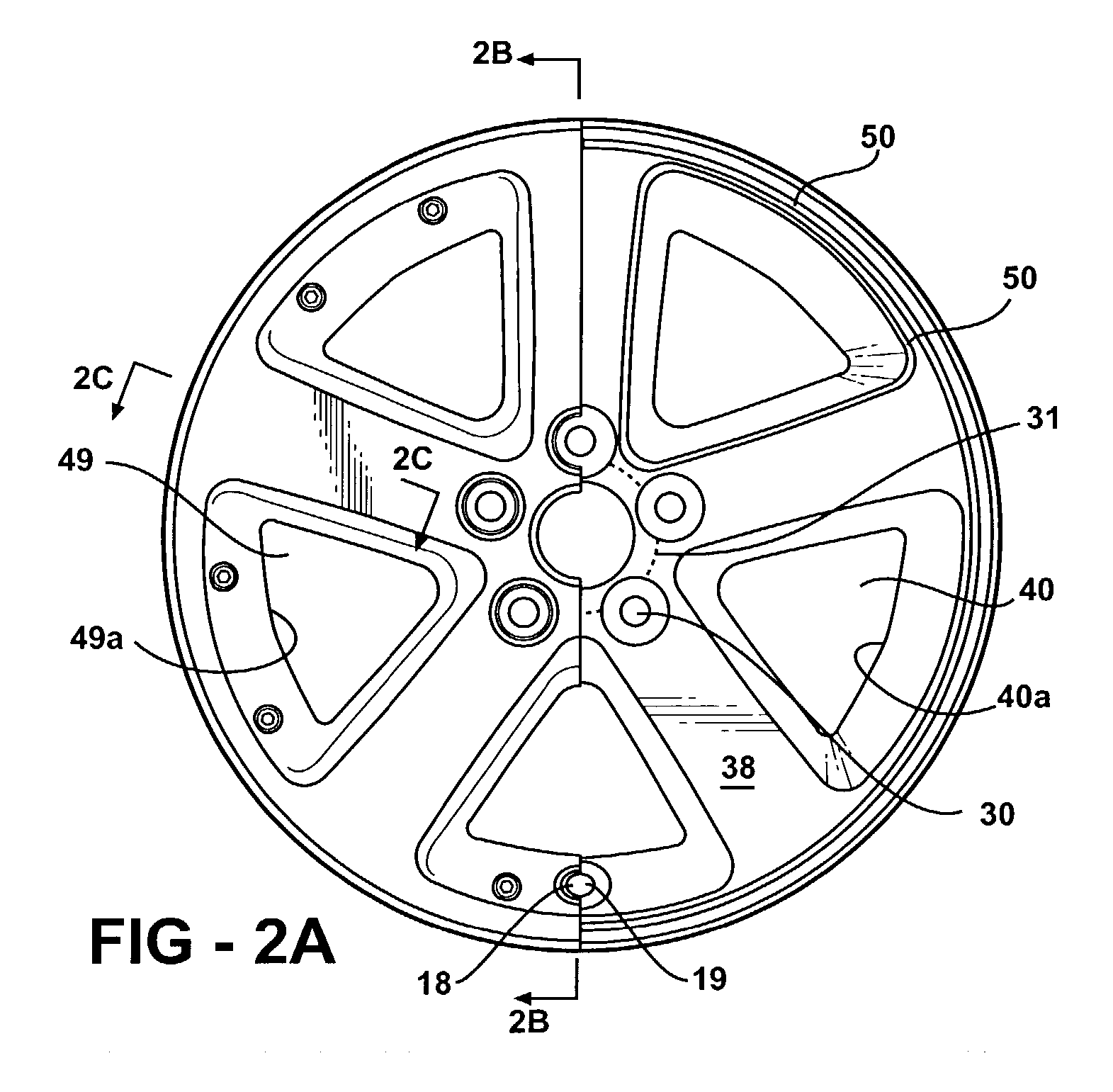

Method and apparatus for assembling a vehicle wheel

ActiveUS7097730B2Economical and reliableImprove adhesionLaminationLamination apparatusEngineeringTurbine

A method and apparatus for attaching an ornamental overlay to a vehicle wheel by injecting adhesive foam through an aperture of the wheel and into a cavity formed between the wheel and the overlay. A first nest engages the outboard side of the wheel / overlay assembly to seal the inner periphery of the overlay, the valve stem opening of the overlay, the lug bolt receiving holes of the wheel, the pilot aperture of the wheel, and / or the valve stem opening of the wheel. A secondary nest engages the inboard side of the wheel / overlay assembly to seal the wheel apertures and a plurality of turbine openings in the overlay. A nozzle disposed within the secondary nest is adapted to inject the adhesive foam into the cavity through either a gap between the periphery of a wheel aperture and the periphery of a corresponding turbine opening in the overlay, through a straight or angled hole within a spoke, or through a groove within a spoke.

Owner:LACKS INDUSTRIES INC

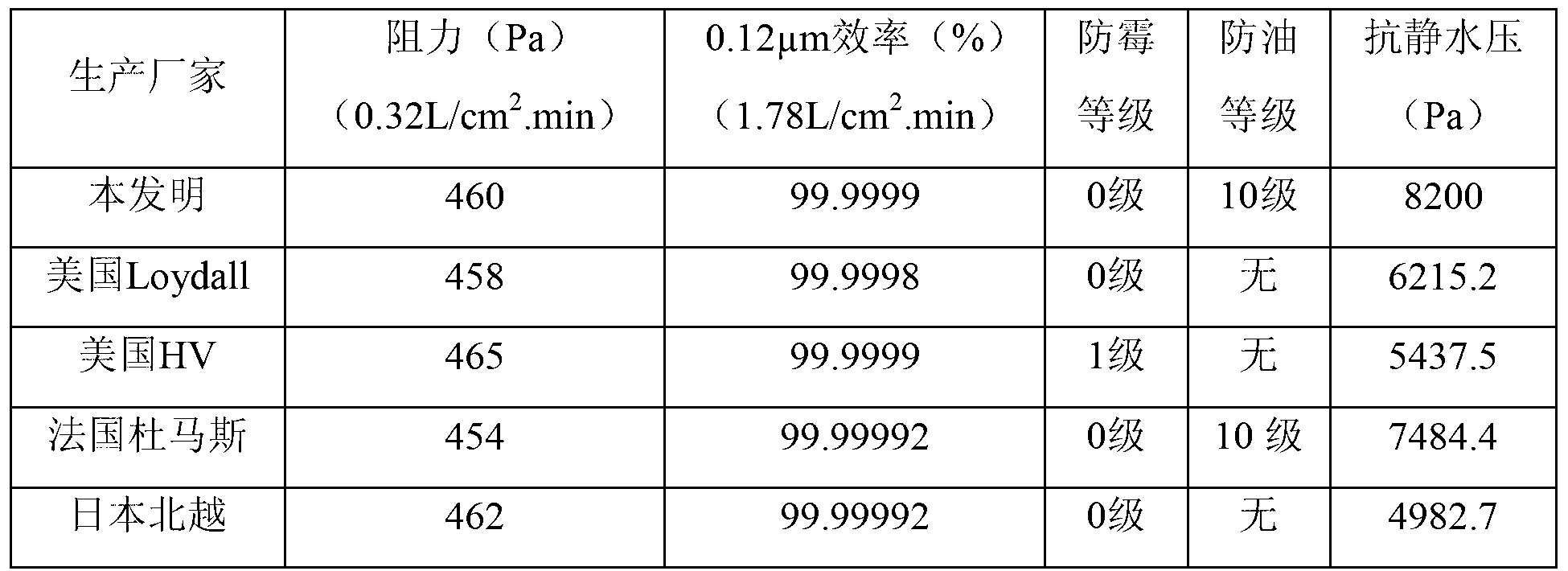

Highly-resistant-to-water core-level glass fiber air filtering paper and preparing method

ActiveCN103243612AReduce porosityLarge specific surface areaPulp beating methodsPaper coatingFiberGlass fiber

The invention discloses a piece of highly-resistant-to-water core-level glass fiber air filtering paper. The filtering paper comprises glass fiber filtering paper made from alkali-free glass fiber with the diameter being 0.1-0.3mu m, 0.5-0.7mu m and 0.8-1.0mu m and from alkali-free glass long fiber with the diameter being 1.4-1.6mu m, and a water-resistant layer attached to the face of the filtering paper and formed by hydrogen silicon oil and acrylic emulsion. The invention also discloses a preparing method for the air filtering paper, which comprises the steps of 1, selecting raw materials according to a proportion, 2, performing pulping to disperse the raw materials to obtain pulp, 3, diluting the pulp and adjusting the PH value, 4, performing slag-removing on the pulp in the step 3 and obtaining wet paper by wet forming, 5 dehydrating the wet paper in the step 4, 6, spraying mixing emulsion of the hydrogen silicon oil, the acrylic emulsion and water on the surface of the wet paper in the step 5; and 7, drying the wet paper in the step 6. The glass fiber air filtering paper has excellent water-resistant property and is suitable for severe environment.

Owner:CHONGQING ZAISHENG TECH CORP

Elaborate brown paper and producing method thereof

InactiveCN101100829AImprove physical strengthGood lookingPulp bleachingChemical/chemomechanical pulpFiberSulfate

The invention relates to elaborate works brown paper and its manufacturing method. It includes the following steps: using more than 60% masson pine, less than 15% cedar, less than 40% various broadleaf wood as material; steam boiling; washing screening; oxidizing delignify; bleaching to form sulfate micro drift wood pulp of which slurry brightness is 24-34%; pulping concentration is 3.5-4.0%; pumping degree is 26-34 degree SR; green weight is 10-15g; de-sanding; fixing; fine screening; forming; pressing; drying; coiling; recoiling; packing. The invention has the advantages of wide material source, low cost, satisfying the demands for cleaning production and food base paper quality.

Owner:YONGZHOU XIANGJIANG PAPER CO LTD

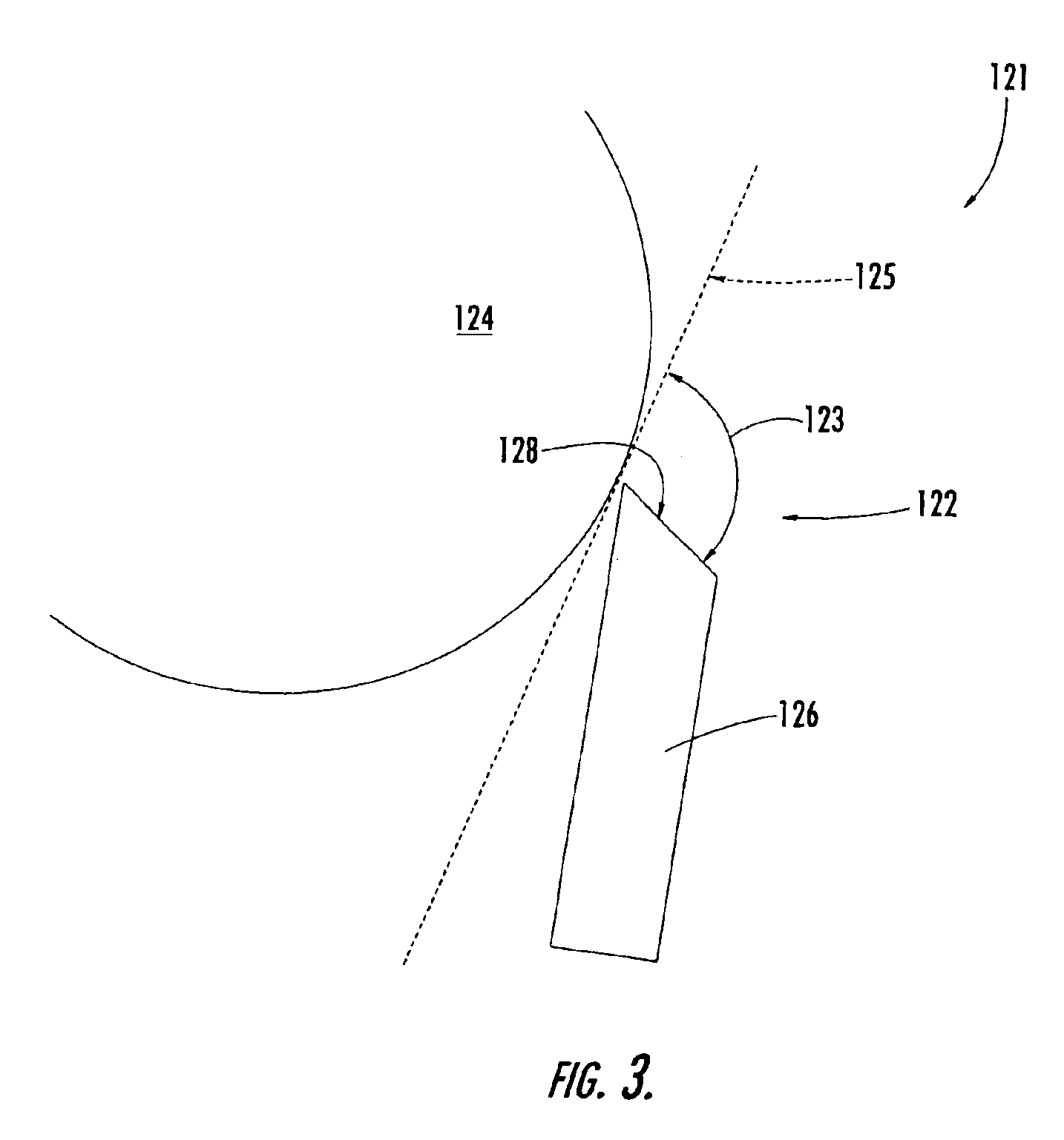

Method and system for manufacturing tissue products, and products produced thereby

InactiveUS6946058B2Good flexibilitySurface is exposedNon-fibrous pulp additionMechanical working/deformationFiberPapermaking

A process and product of making a tissue product is provided. For example, the method can comprise (a) providing a first papermaking furnish containing refined softwood fibers; (b) providing a second papermaking furnish containing hardwood fibers; (c) incorporating the first and second papermaking furnishes into a tissue web such that the tissue web has a hardwood layer and a softwood layer; (d) contacting the tissue web with a drying surface so that the hardwood layer is disposed adjacent thereto; and (e) removing the tissue web from the drying surface with a creping blade at a creping pocket angle of less than about 82 degrees.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Production method of glassine body paper

InactiveCN102888778AHigh transparencyHigh tensile strengthWater-repelling agents additionChemical/chemomechanical pulpPaper sheetWetting

The invention discloses a production method of glassine body paper. The method comprises the following steps: A. blending the slurry after preparing, wherein the slurry consists of bleaching sulfate needle wooden pulp, and the concentration of the slurry is controlled in the range from 40 to 50 OSR; B. adding sizing agent; C. feeding the materials into a flow box for manufacturing paper with pulp; D. squeezing and dehydrating; E. feeding paper sheets into the front dry part; F. sizing on the surface; G. feeding the paper sheets entering into the rear dry part; H. moisting the paper sheets through a spraying and wetting system, wherein the spraying amount is 7-8% (based on weight), the water after spraying reaches 12-16% (based on weight); I. decorating the paper through super press polishing; and J. reeling, cutting and packaging. The body paper produced by the invention has the beneficial effects of ultrahigh transparency, ultrahigh tensile strength, better paper smoothness and lower surface oil absorption factor, wherein the transparency is greater than or equal to 40%, the vertical tensile strength is greater than or equal to 6kN / m<2>, the smoothness is greater than or equal to 1500s, the tightness is greater than or equal to 1.1g / m<3>, and the surface oil absorption factor is less than or equal to 1.0g / m<2>.

Owner:XIANHE CO LTD

Exquisite kraft paper and producing method thereof

ActiveCN101255670AImprove physical strengthGood lookingPulp bleachingPaper-making machinesMasson pineKraft paper

Owner:YUEYANG FOREST & PAPER CO LTD

Total heat exchanging element-use paper

InactiveUS20030226656A1Reduced strengthImprove permeabilityNon-fibrous pulp additionAir treatment detailsWater vapor permeabilityWater vapor

The object of the present invention is to provide an excellent total heat exchanging element paper and a total heat exchanging element which are excellent in heat transferability, water vapor permeability and gas barrier properties and cause no mixing of supplied air and discharged air. The present invention provides a total heat exchanging element paper using a paper made using mainly a natural pulp beaten to a Canadian modification freeness of not more than 150 ml, a substantially non-porous total heat exchanging element paper comprising a substantially non-porous cellulosic base which contains a moisture absorbing agent, a non-porous total heat exchanging element paper having a high gas barrier property which has a thickness of not more than 100 mum and a carbon dioxide permeation constant specified in JIS K7126 of not more than 5.0x10<-13 >mol.m / m<2>.s.Pa, and a non-porous total heat exchanging element paper having a high enthalpy exchangeability which has a water vapor permeability specified in JIS Z0208 of not less than 1000 g / m<2>.24 Hr at 20° C. and 65%RH.

Owner:MITSUBISHI PAPER MILLS LTD

Vibration-induced die detachment system

ActiveUS20090032186A1Reduce deformationReduced risk of cracking and deformationSlide fastenersSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

A die is detachable from an adhesive tape on which the die is mounted with a die detachment tool comprising a vacuum enclosure that is operative to provide a vacuum suction on the adhesive tape. One or more ejector pins are housed in the vacuum enclosure and are projectable from the vacuum enclosure for lifting the die and adhesive tape. A vibrational tool is housed in the vacuum enclosure adjacent to the ejector pins and it is projectable from the vacuum enclosure to contact a portion of the adhesive tape at which the die is located. The vibrational tool is further operative to oscillate the adhesive tape and die for promoting delamination of the die from the adhesive tape.

Owner:ASM ASSEMBLY AUTOMATION LTD

Device for thin die detachment and pick-up

ActiveUS8141612B2Relieve pressureLamination ancillary operationsSlide fastenersMechanical engineeringMental detachment

Owner:ASM ASSEMBLY AUTOMATION LTD

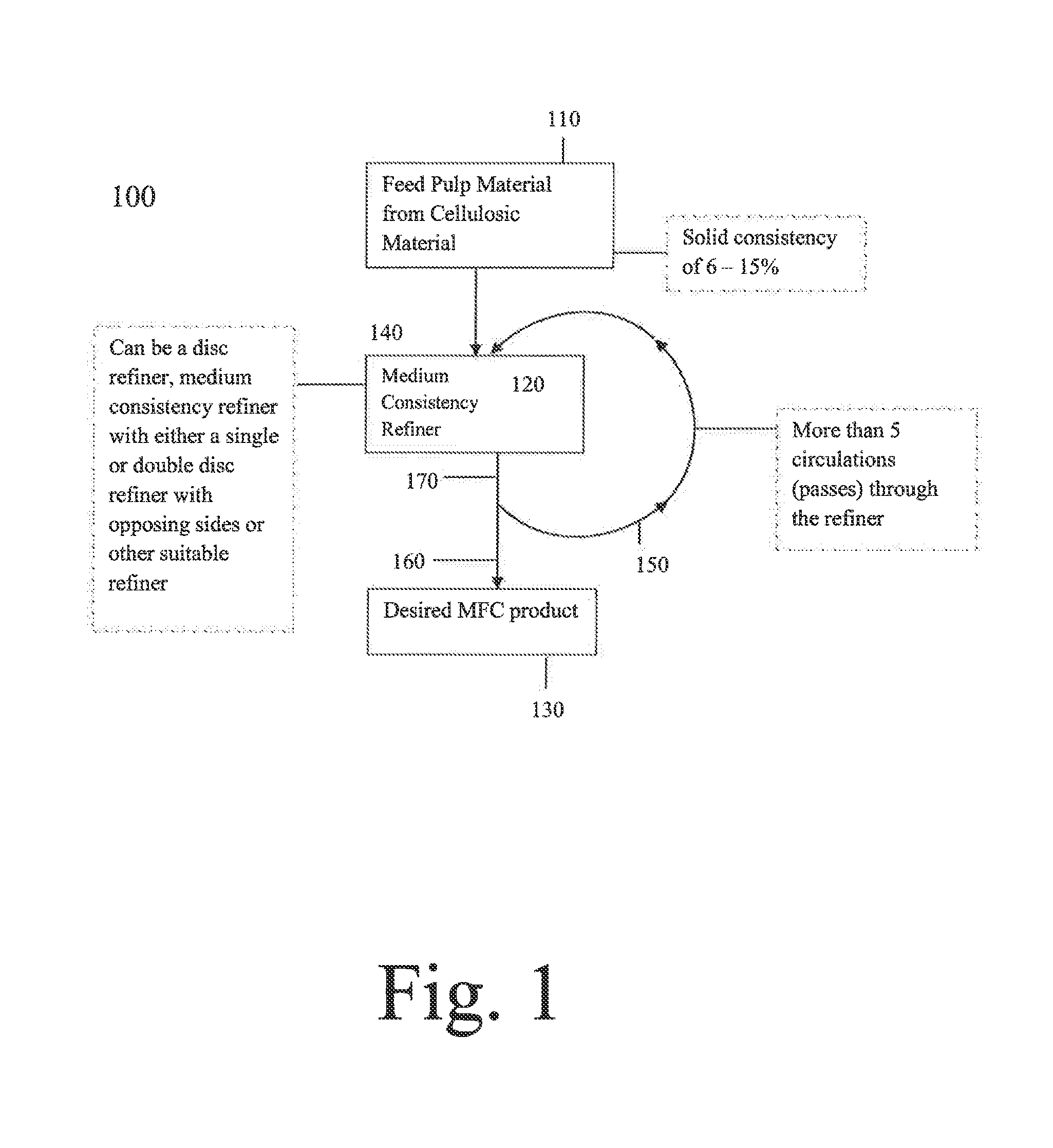

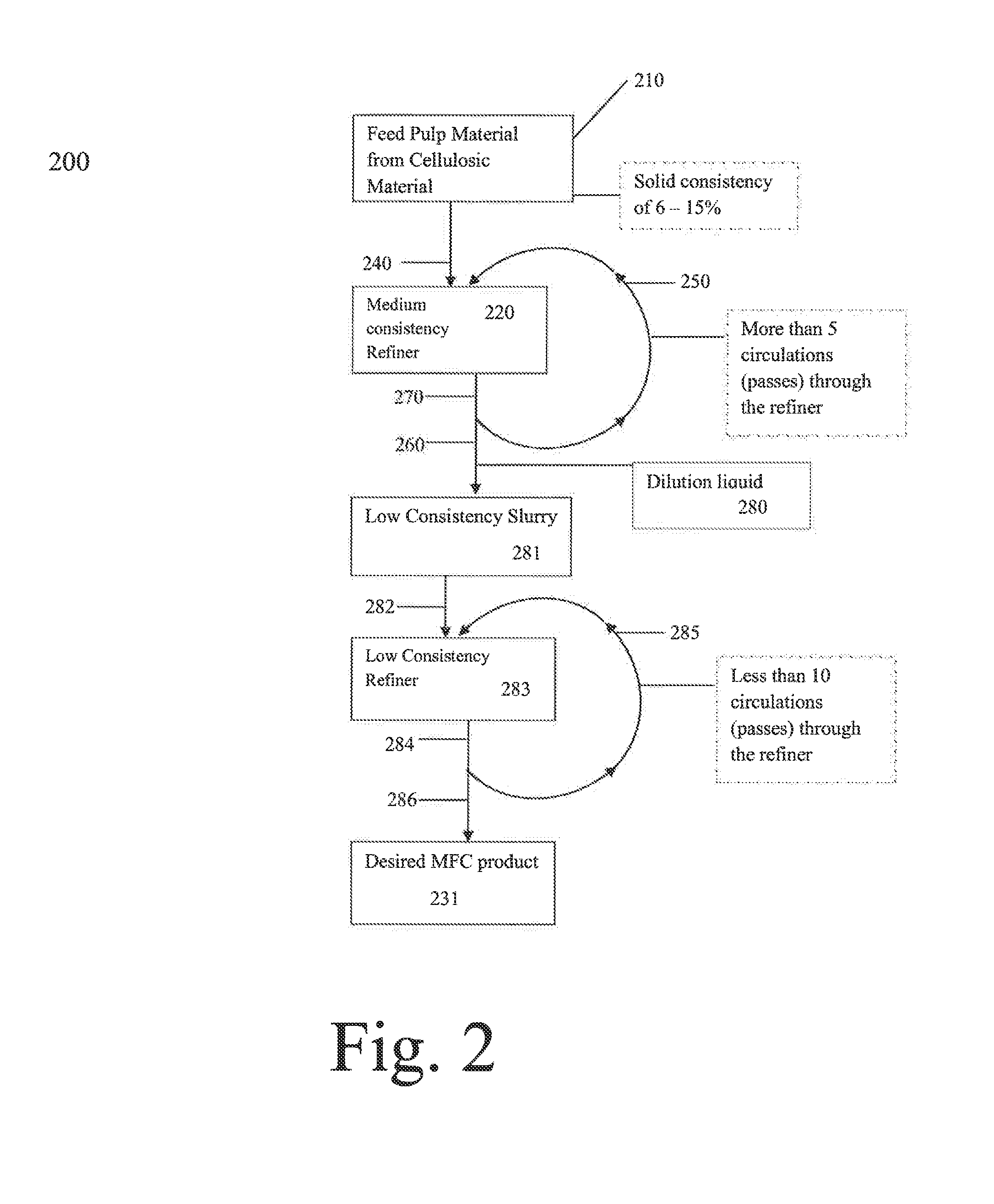

Method for production of micro fibrillated cellulose

Owner:ANDRITZ INC

Floor strip

InactiveUS20050217193A1Increase resistanceSmooth transitionWallsWood working apparatusReducerEngineering

A thin decorative thermosetting laminate of postforming quality is glued to a longitudinal carrier to form a floor strip. The laminate has a thermosetting resin as well as hard particles impregnated therein to increase the abrasion resistance of the laminate. The carrier generally has a cross section of a dilatation, transition or a finishing profile, depending on the intended use of the floor strip. The floor strip has a tab portion on a surface that engages a channel on a floor tile or a reducer. The tab portion locks the floor strip into place and prevents movement of the floor tile or the reducer with respect to the floor strip.

Owner:PERGO

Method for manufacturing glass isolation paper

The invention discloses a method for manufacturing glass isolation paper. According to the method, high-grade bleach sulfate softwood pulp is used as a raw material, and the glass isolation paper which is high in strength, stable in pH value, uniform in thickness, good in smoothness, high in cleanliness and good in softness is prepared through process steps of pulping and auxiliary material adding, wet paper page manufacturing with pulp, pressing dewatering, pre-drying, surface sizing and after-drying and the like.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

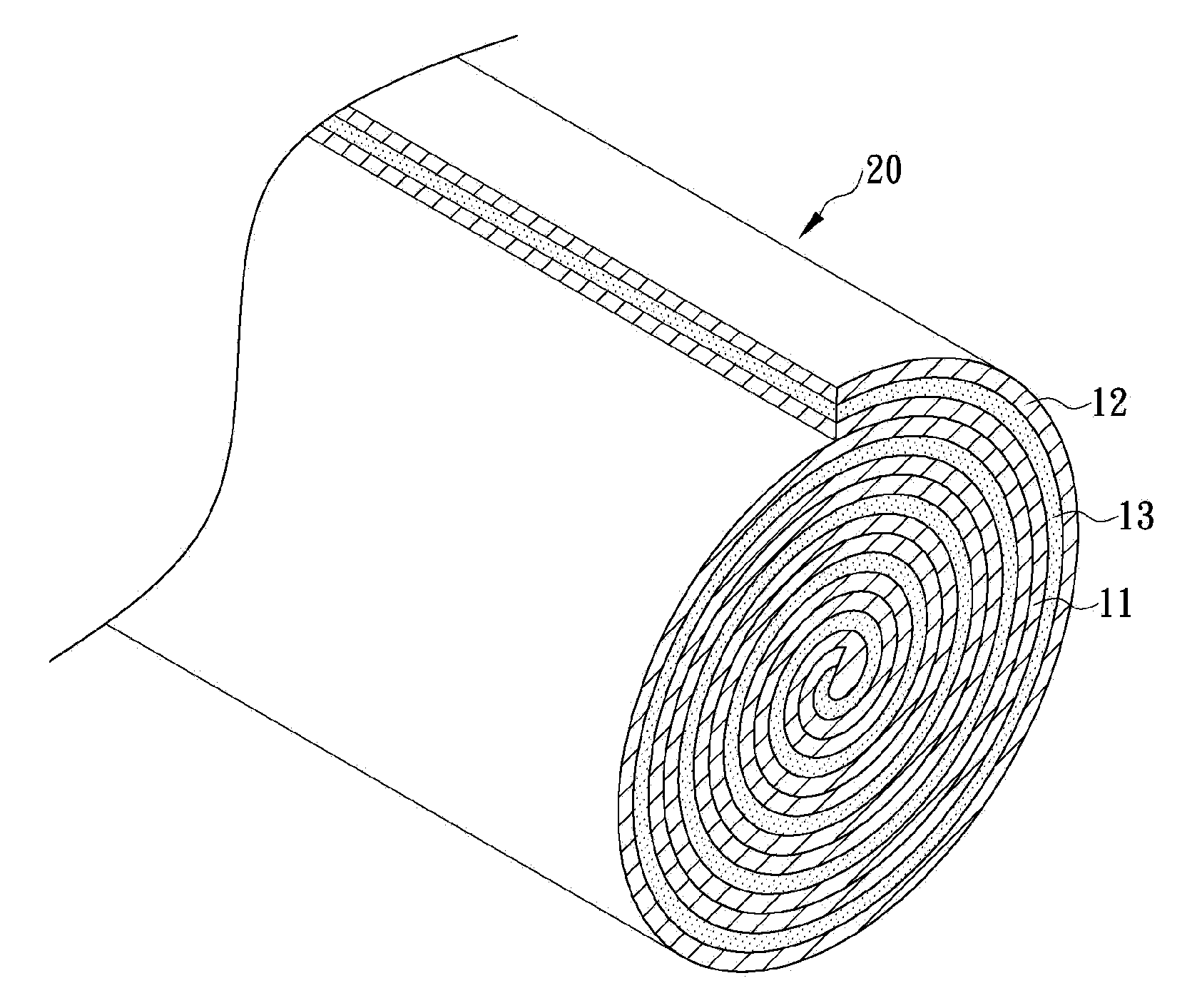

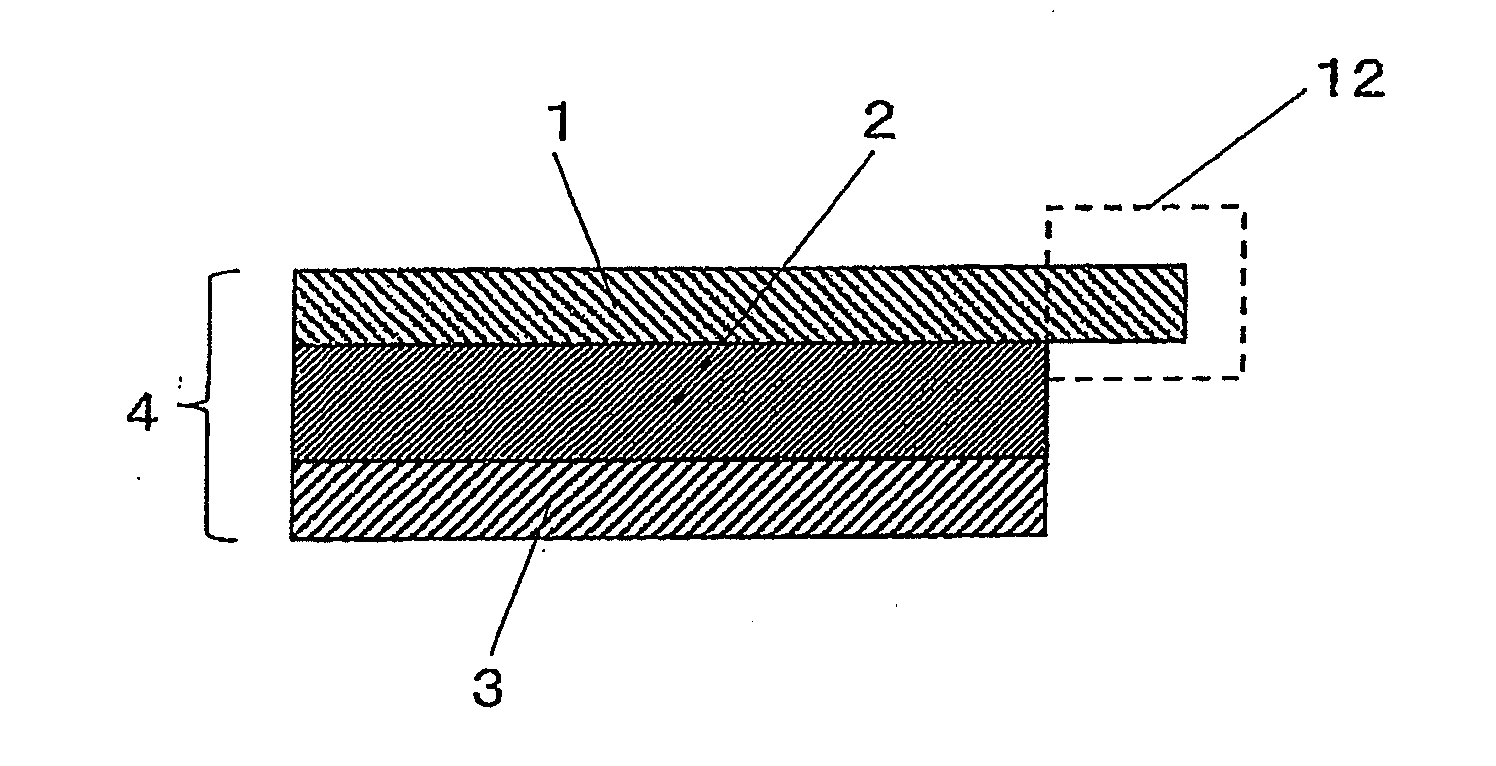

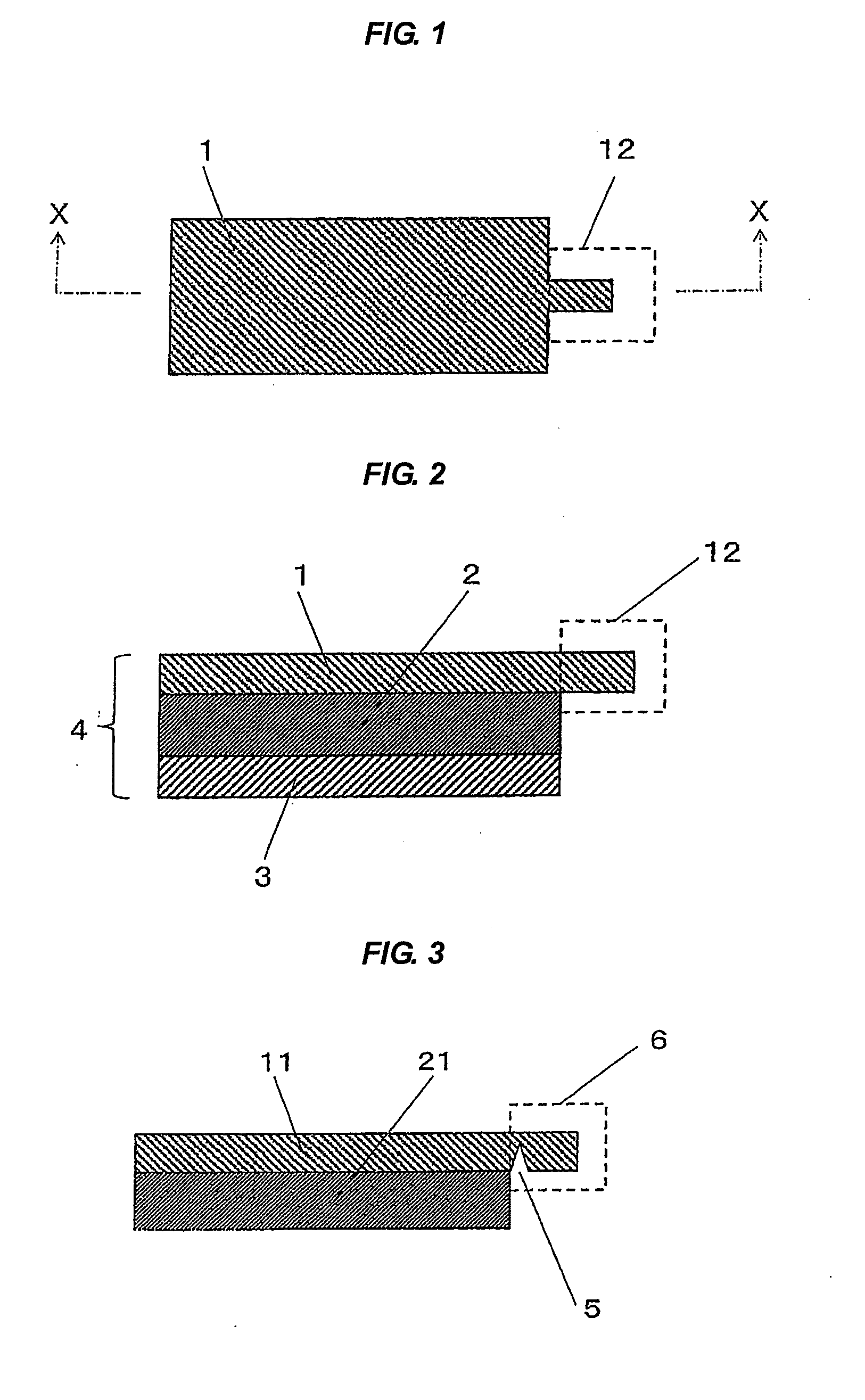

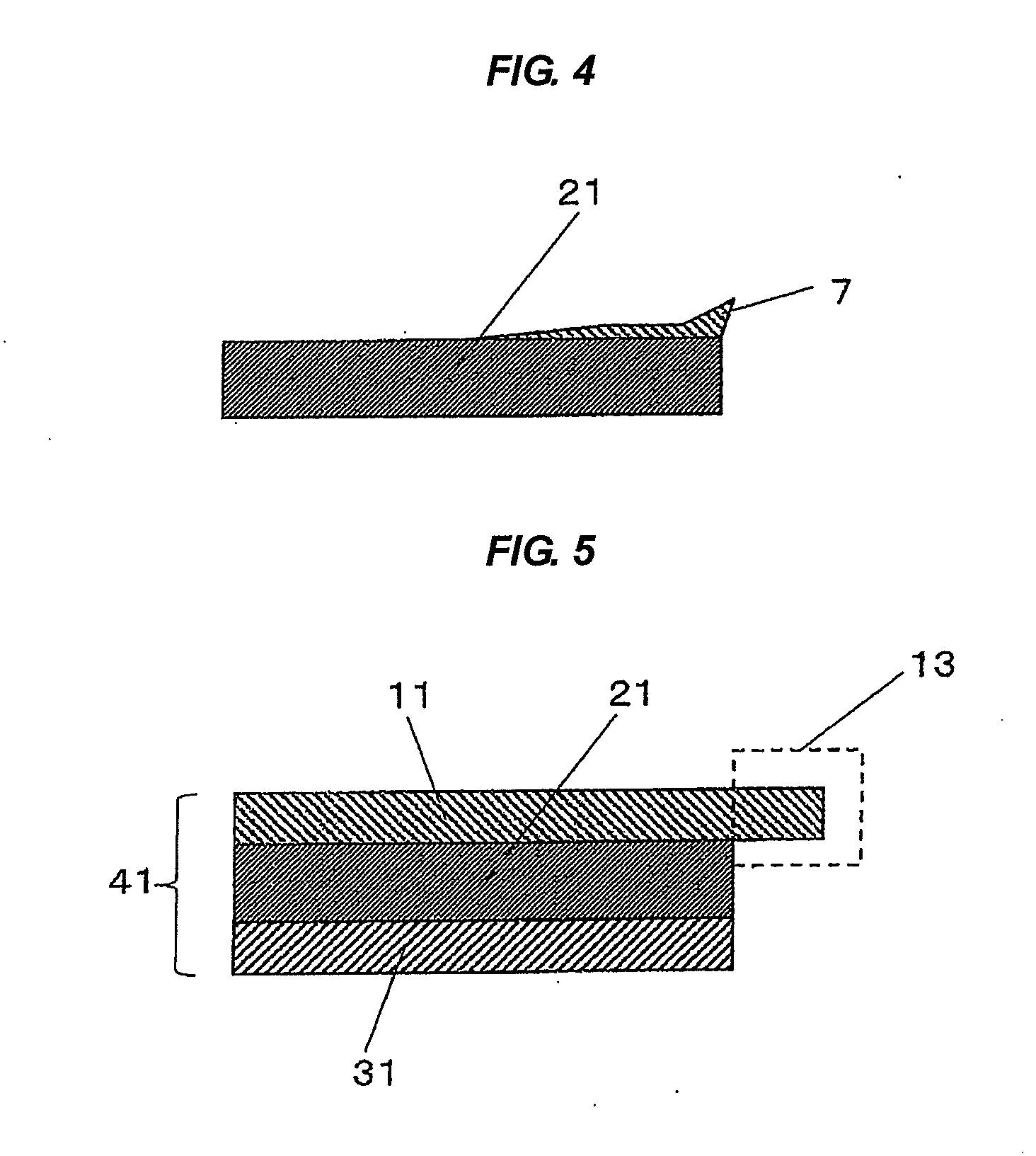

Method for manufacturing microfibrous cellulose composite sheets and method for manufacturing microfibrous cellulose composite sheet laminate

ActiveUS8663425B2Efficient productionSmall widthNon-fibrous pulp additionPaper after-treatmentCellulosePolymer science

The present invention provides a method for easily and efficiently manufacturing microfibrous cellulose composite sheets. The present invention is a method for manufacturing microfibrous cellulose composite sheets, including a preparation process in which a polymer emulsion is mixed with an aqueous suspension including microfibrous cellulose, thereby preparing a mixed fluid, a papermaking process in which the mixed fluid is dehydrated on a porous base material through filtration, and a sheet including moisture is formed, and a drying process in which the sheet including moisture is heated and dried. In addition, the present invention is a method for manufacturing a microfibrous cellulose composite sheet laminate, in which the microfibrous cellulose sheets are thermally compressed and thus laminated as they are or after being provided with a polymer layer on at least one surface thereof.

Owner:OJI HLDG CORP

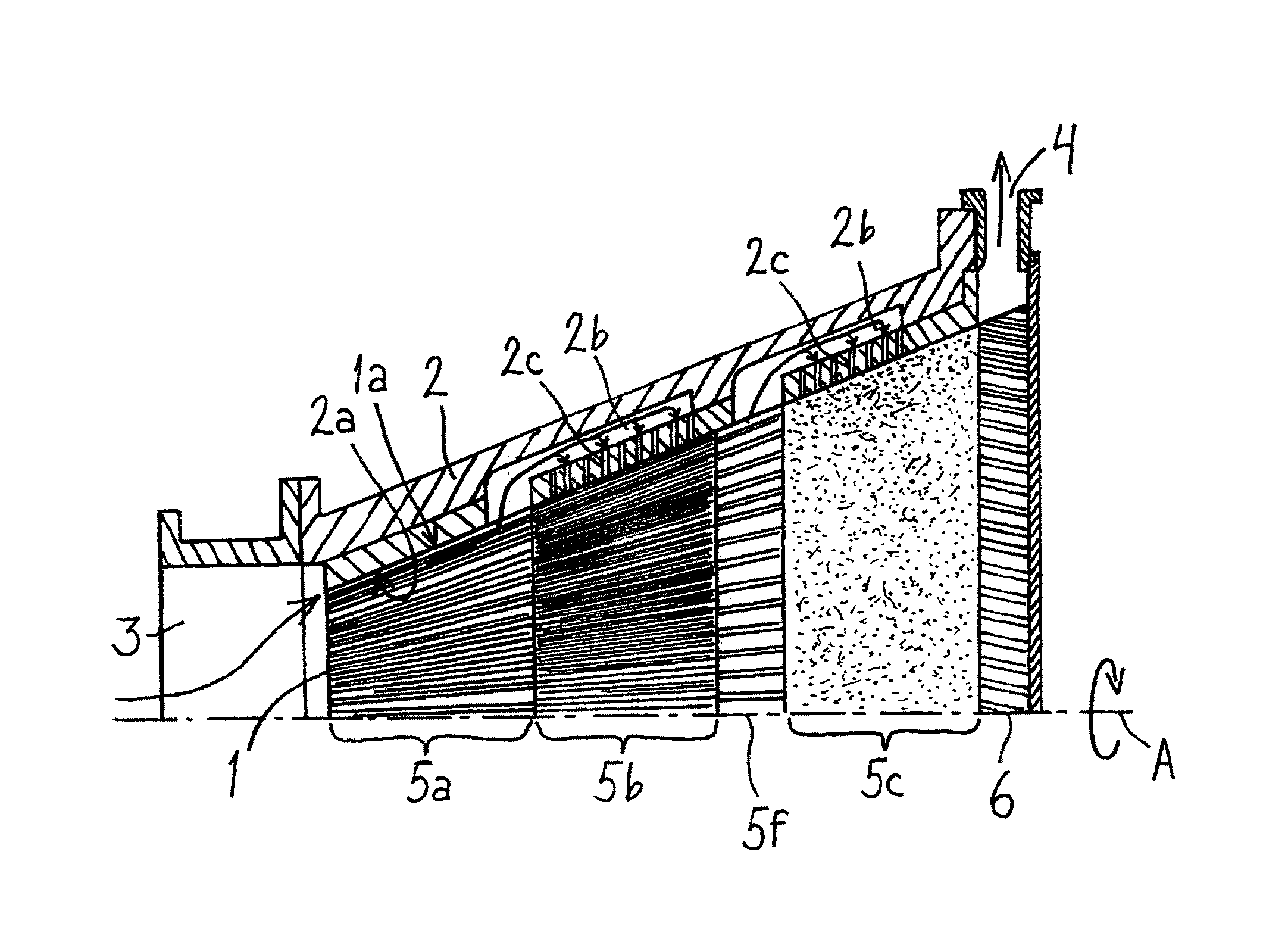

Double-sided pressure-sensitive adhesive sheet

InactiveUS20130142982A1Excellent peeling operabilityEasy to operateLayered productsEster polymer adhesivesPaper basedFlexible electronics

There is provided a double-sided pressure-sensitive adhesive sheet including a pressure-sensitive adhesive body having pressure-sensitive adhesive faces (a) and (b) on both sides thereof, and a release liner (A) provided at least on the pressure-sensitive adhesive face (a) of the pressure-sensitive adhesive body. The release liner (A) includes a paper-based base material and a release layer on a face of the paper-based base material, the release layer being in contact with the pressure-sensitive adhesive face (a). The ratio of an interlayer strength of the release liner (A) with respect to a peeling force of the release liner (A) in a peeling test at 90° with respect to the pressure-sensitive adhesive face (a) is 15 or more. The double-sided pressure-sensitive adhesive sheet may preferably be used as a double-sided pressure-sensitive adhesive sheet for a flexible printed circuit board.

Owner:NITTO DENKO CORP

Coated base paper and a method for manufacturing coated base paper

InactiveUS20060231226A1Reduce decreaseNon-fibrous pulp additionNatural cellulose pulp/paperPolyvinyl alcoholPaper based

The object of the invention is coated base paper. According to the invention, it comprises cellulose fibres based pigment-coated paper having 1 to 5 barrier layers. The barrier layer comprises a barrier chemical selected from the group comprising polyvinyl alcohol, acrylate-based barrier latexes and their mixtures. The object of the invention is also a method for the manufacture of coated base paper. In the method, onto a pigment-coated paper based on cellulose fibres 1-5 barrier layers are applicated by using a method not contacting the web.

Owner:M REAL OYJ

Glass paper production process

ActiveCN103541278AQuality improvementEmission reductionVegetable/imitation parchmentAdhesivePaper production

The invention discloses a glass paper production process which comprises the following steps of (1), extracting; (2), repulping; (3), carrying out ultrasonic treatment; (4), floating; (5), washing; (6), preparing an adhesive; (7), carrying out a film production procedure; and (8), carrying out a forming procedure. The glass paper production process is reasonable in process, and environment-friendly and practical in raw materials; resources are fully utilized, the process cost is lower; the pollutant emission is less, and most importantly, the paper quality is improved; the paper package is more environment-friendly and economic. The glass paper production process is suitable for being popularized and used in the paper package industry.

Owner:TONGCHENG FURUN PACKAGING MATERIAL

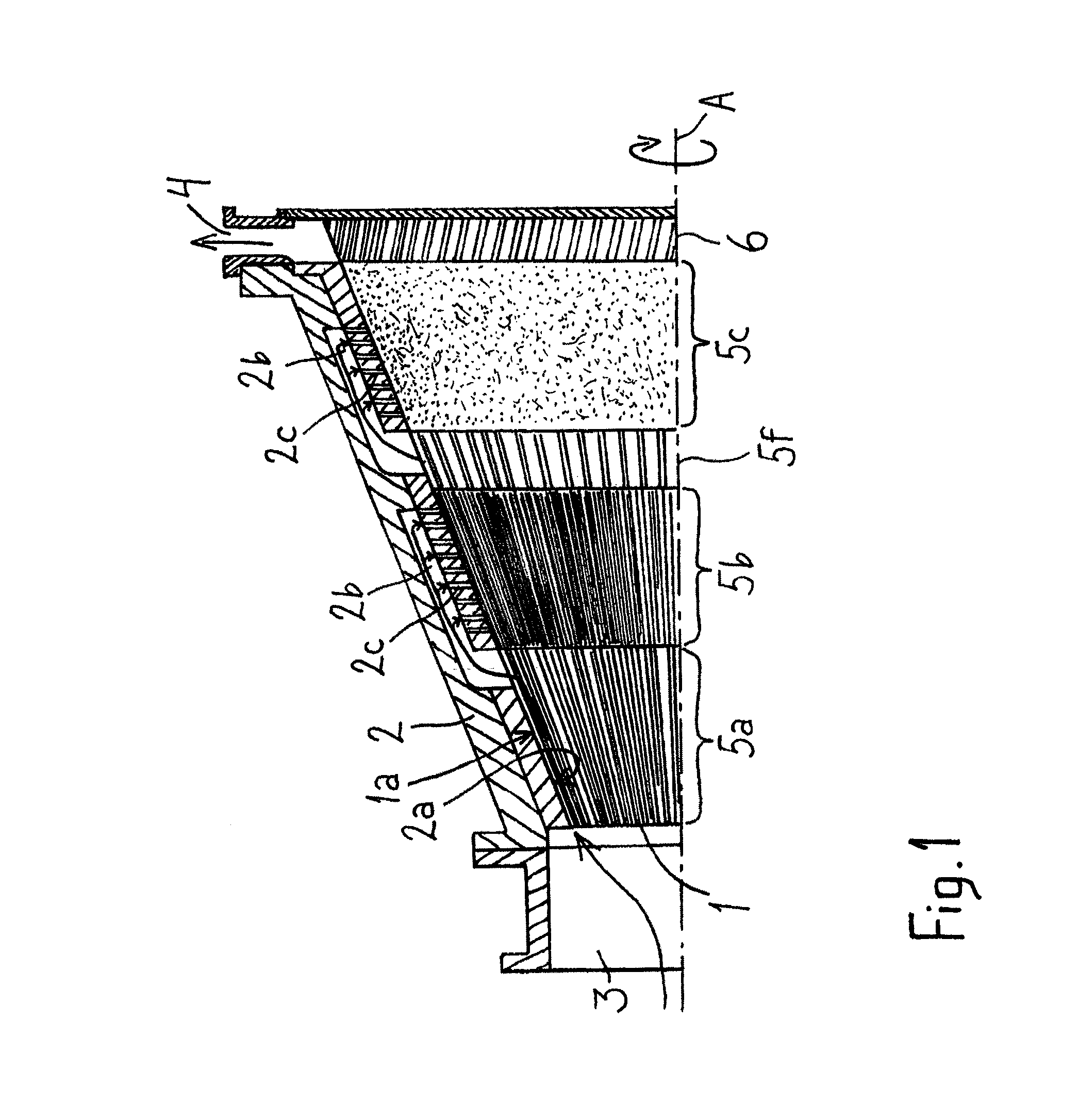

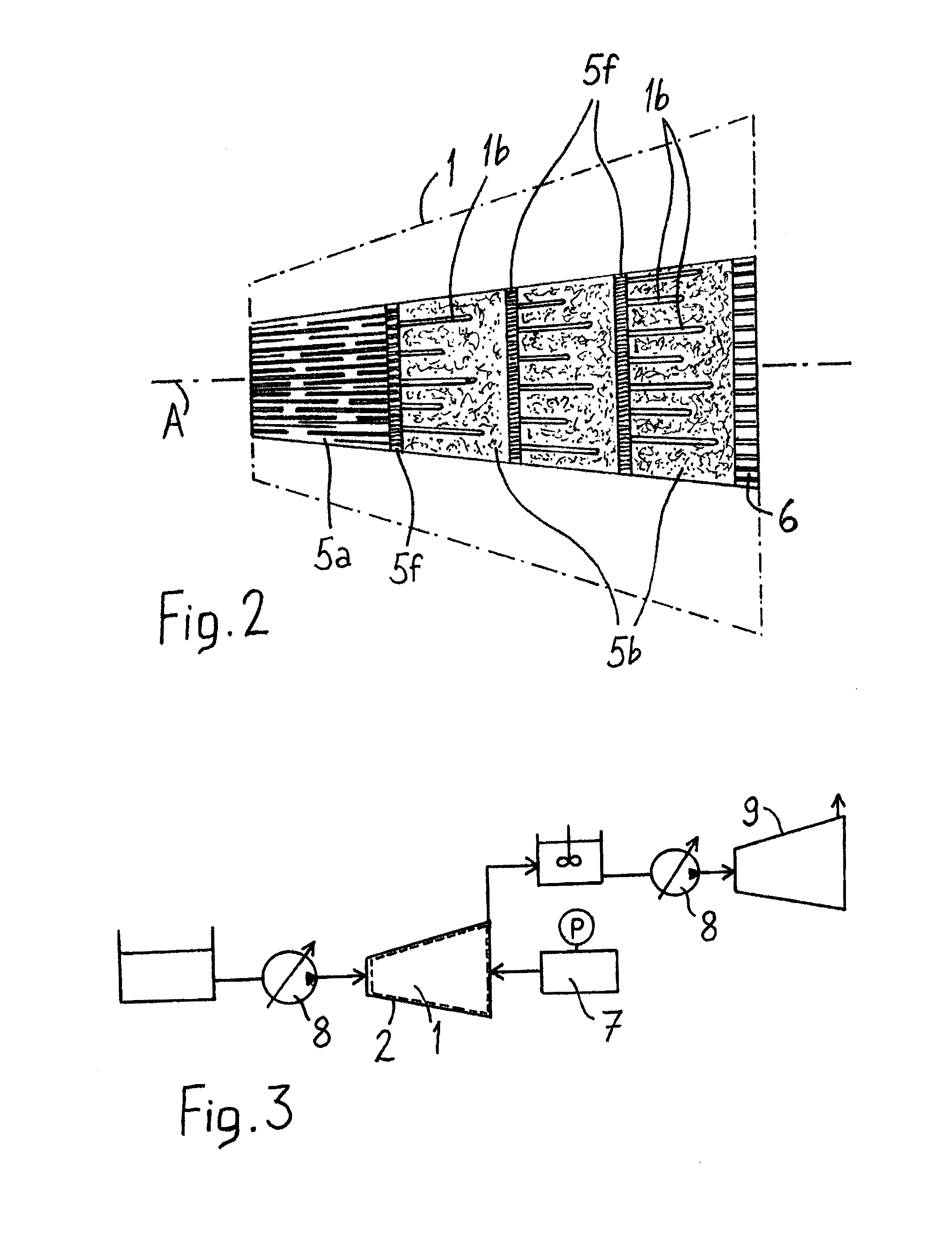

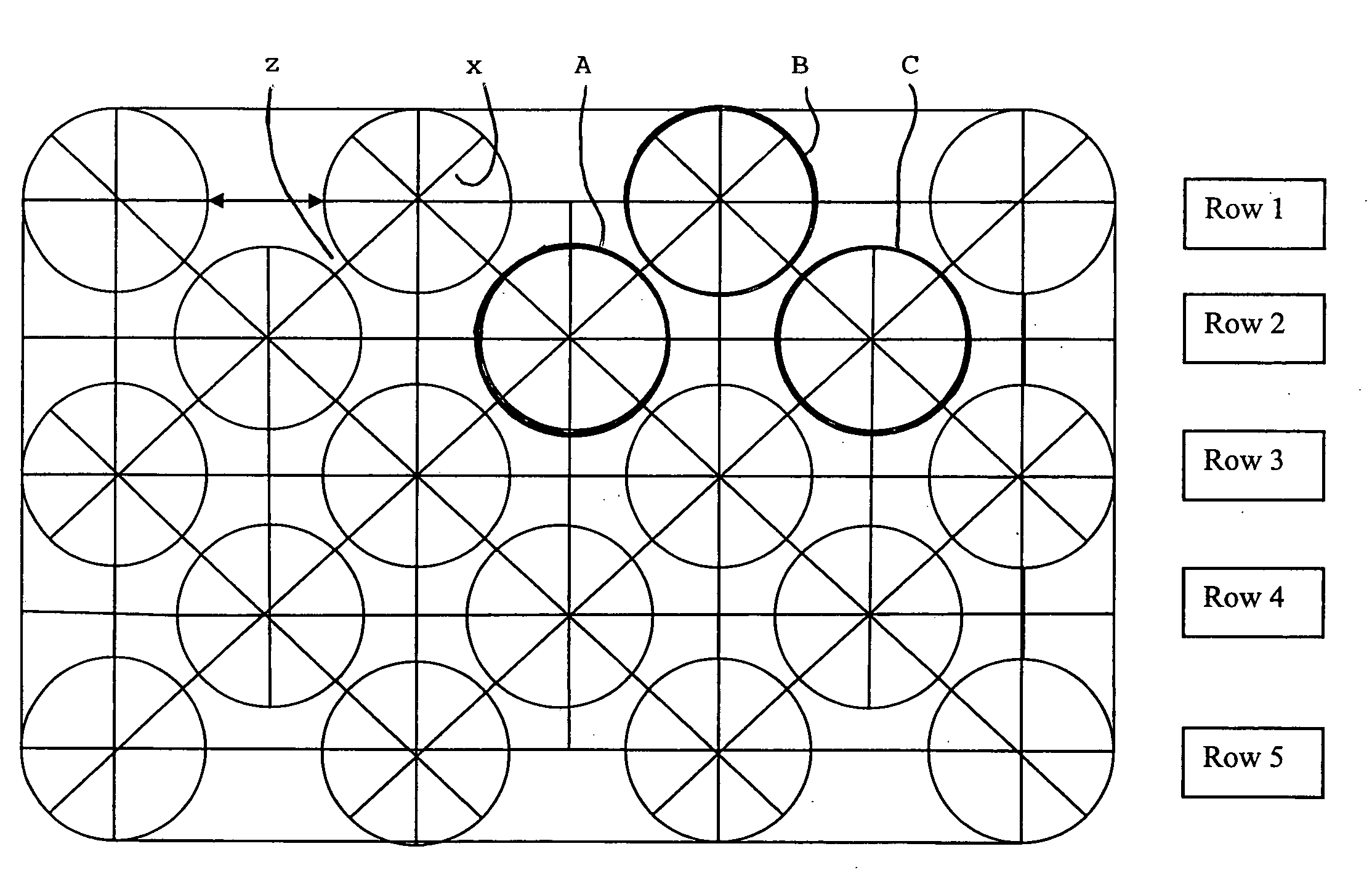

Method and an apparatus for producing nanocellulose

InactiveUS8945346B2Easy to implementCellulosic pulp after-treatmentNon-fibrous pulp additionFiberMetallurgy

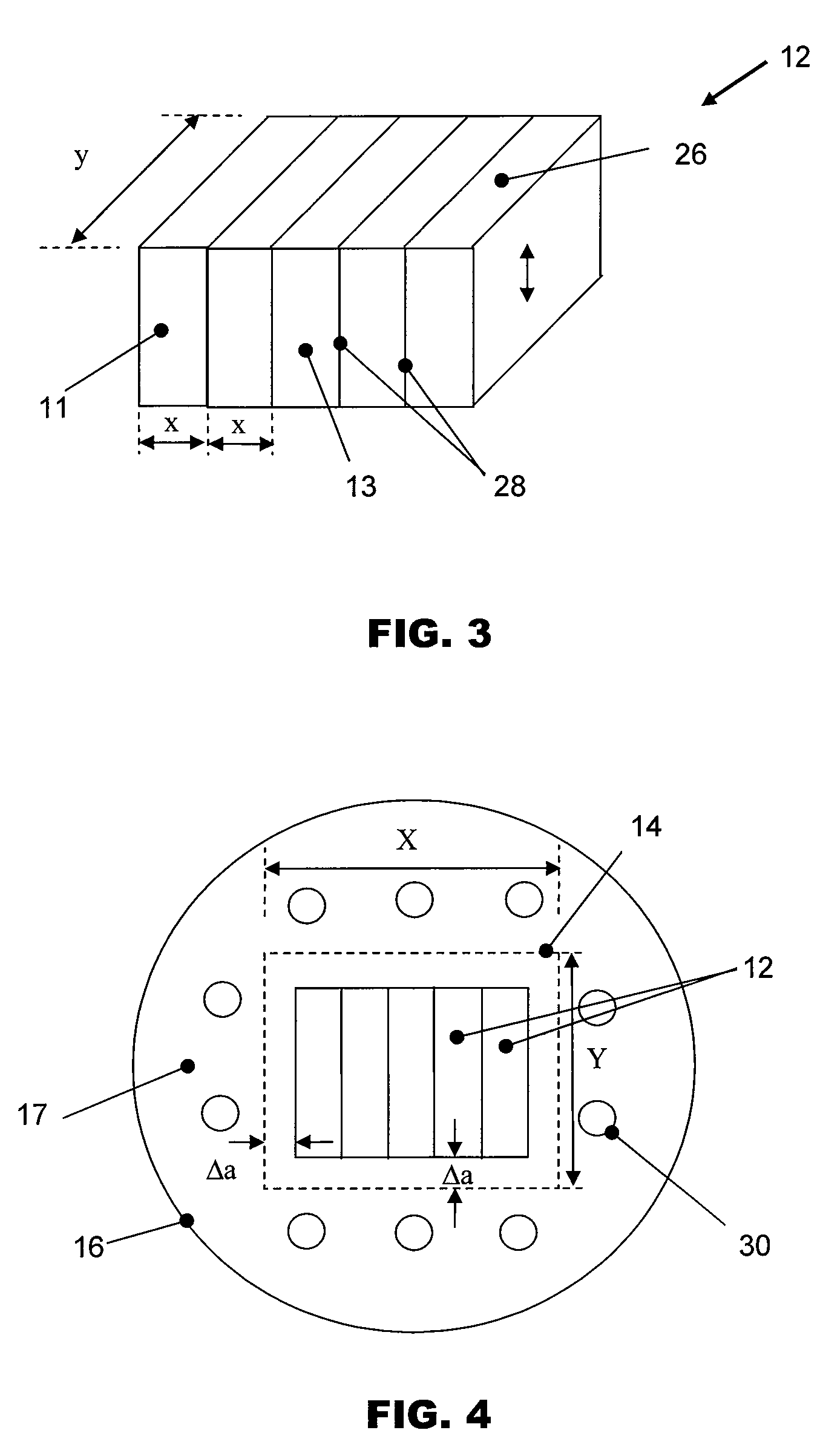

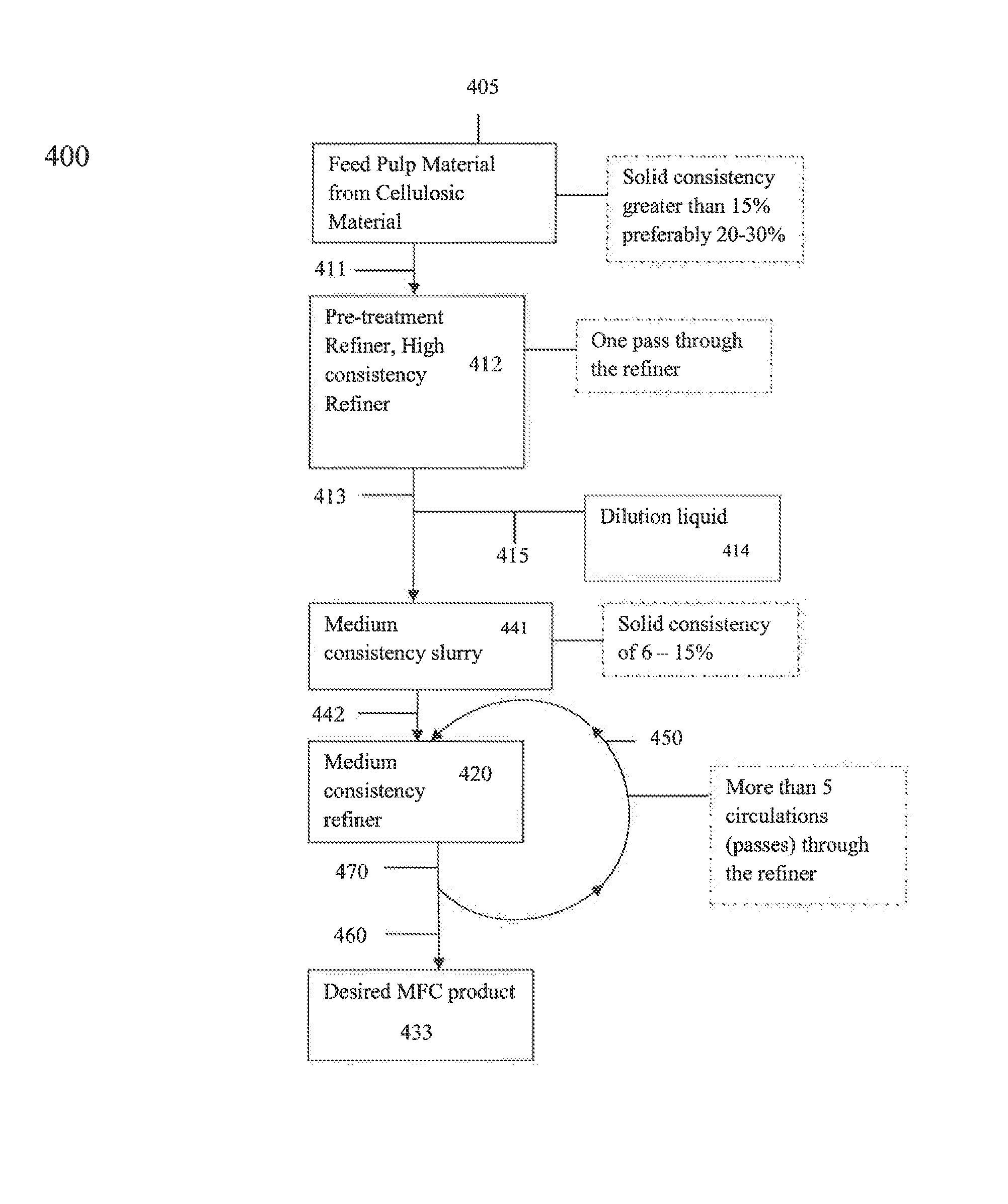

Described herein is nanocellulose produced by introducing a mixture of cellulose based fiber raw material and water through a refining gap, having a width smaller than 0.1 mm. In the refining gap, the fiber raw material is subjected to processing forces varying in the direction of introducing said mixture, by means of refining zones provided in the gap one after each other in the feeding direction, whereby the refining surfaces differ in surface patterning and / or surface roughness. The mixture of fiber raw material and water is guided past the refining surfaces in the feeding direction to different locations in the refining zone by by-pass channels provided in the stator. The width of the refining gap is maintained by the combined effect of the feeding pressure of the mixture of fiber raw material and water fed into the refining gap and the axial force of the rotor.

Owner:UPM-KYMMENE OYJ

Transparent paper and method of making same

The invention teaches a novel paper substrate having a transparent field of a dense array of a plurality of laser-formed microperforations. The resultant paper can be useful as a replacement for glassine paper, and can be useful in secure documents. The transparent field is integral to the paper substrate and can be formed by laser techniques surprisingly resulting in a transparent field retaining acceptable strength characteristics after lasing. The transparent field acts as a self authentication device.

Owner:APPLETON PAPERS INC

Production method of color imitation parchment paper

ActiveCN102433801AGood paper surface softnessImprove visual effectsVegetable/imitation parchmentSlurrySizing

The invention relates to a production method of color imitation parchment paper, comprising the following steps of: carrying out paper making on a prepared slurry by using a paper machine, controlling the jet / wire speed ratio to form a well-proportioned pattern floc aggregate-carrying wet paper sheet with poor uniformity; finishing the paper surface by a pressure roller before applying glue onto the surface, planishing several tiny convex portions on the paper surface to form a paper sheet containing different bulk densities of pattern floc aggregates; applying glue onto the surface of the above paper sheet by a surface sizing applicator to form a sized paper sheet with a dense-dilute color pattern, wherein dyes are added in a surface sizing solution; drying to form a paper sheet with strong stereoscopic impression, and slitting to obtain the finished product color imitation parchment paper. According to the invention, the technological flow is simple, the production technology is stable and reliable, and the produced parchment paper has very strong stereoscopic impression and artistic effects. The paper surface has good soft texture, brilliant color, and strong sheepskin visual effect.

Owner:SHANDONG KAILI SPECIAL PAPER

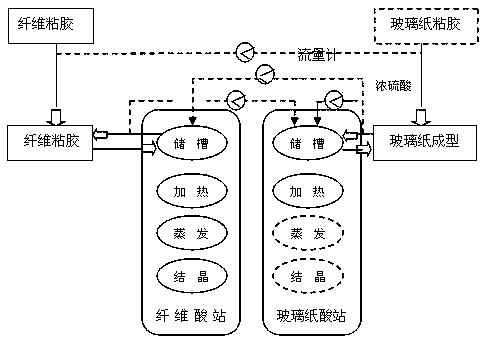

Acid bath process for glass paper production

ActiveCN105369689ALess investmentReduce consumptionVegetable/imitation parchmentPaper productionPulp and paper industry

The invention discloses an acid bath process for glass paper production. The process is as below: integrating a glass paper acid bath and a viscose fiber acid bath by merging recycling acid of glass paper into the acid bath of viscose fiber, evaporating and crystallizing; and then merging the viscose fiber acid bath into the glass paper acid bath to supplement the concentration of the glass paper acid bath. The process reduces independent evaporation of the glass paper and crystallization equipment investment; larger evaporation of viscose fiber and crystallization equipment are utilized to reduce the overall energy consumption; the reduction of composition process concentration (sulfuric acid) reduces the consumption of chemical materials; and the operating and maintenance personnel are reduced.

Owner:CHENGDU GRACE FIBER

Total heat exchanging element paper

InactiveUS20130233529A1Non-fibrous pulp additionAir treatment detailsWater vapor permeabilityWater vapor

The object of the present invention is to provide an excellent total heat exchanging element paper and a total heat exchanging element which are excellent in heat transferability, water vapor permeability and gas barrier properties and cause no mixing of supplied air and discharged air. The present invention provides a total heat exchanging element paper using a paper made using mainly a natural pulp beaten to a Canadian modification freeness of not more than 150 ml, a substantially non-porous total heat exchanging element paper comprising a substantially non-porous cellulosic base which contains a moisture absorbing agent, a non-porous total heat exchanging element paper having a high gas barrier property which has a thickness of not more than 100 μm and a carbon dioxide permeation constant specified in JIS K7126 of not more than 5.0×10−13 mol·m / m2·s·Pa, and a non-porous total heat exchanging element paper having a high enthalpy exchangeability which has a water vapor permeability specified in JIS Z0208 of not less than 1000 g / m2·24 Hr at 20° C. and 65% RH.

Owner:MITSUBISHI PAPER MILLS LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com