Coated base paper and a method for manufacturing coated base paper

a technology of coating base paper and coating paper, which is applied in the field of coating base paper and a manufacturing method of coating base paper, can solve the problems of affecting the quality of coating paper, the deterioration of coating paper, etc., and the surface remains uneven and the effect of reducing the number of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

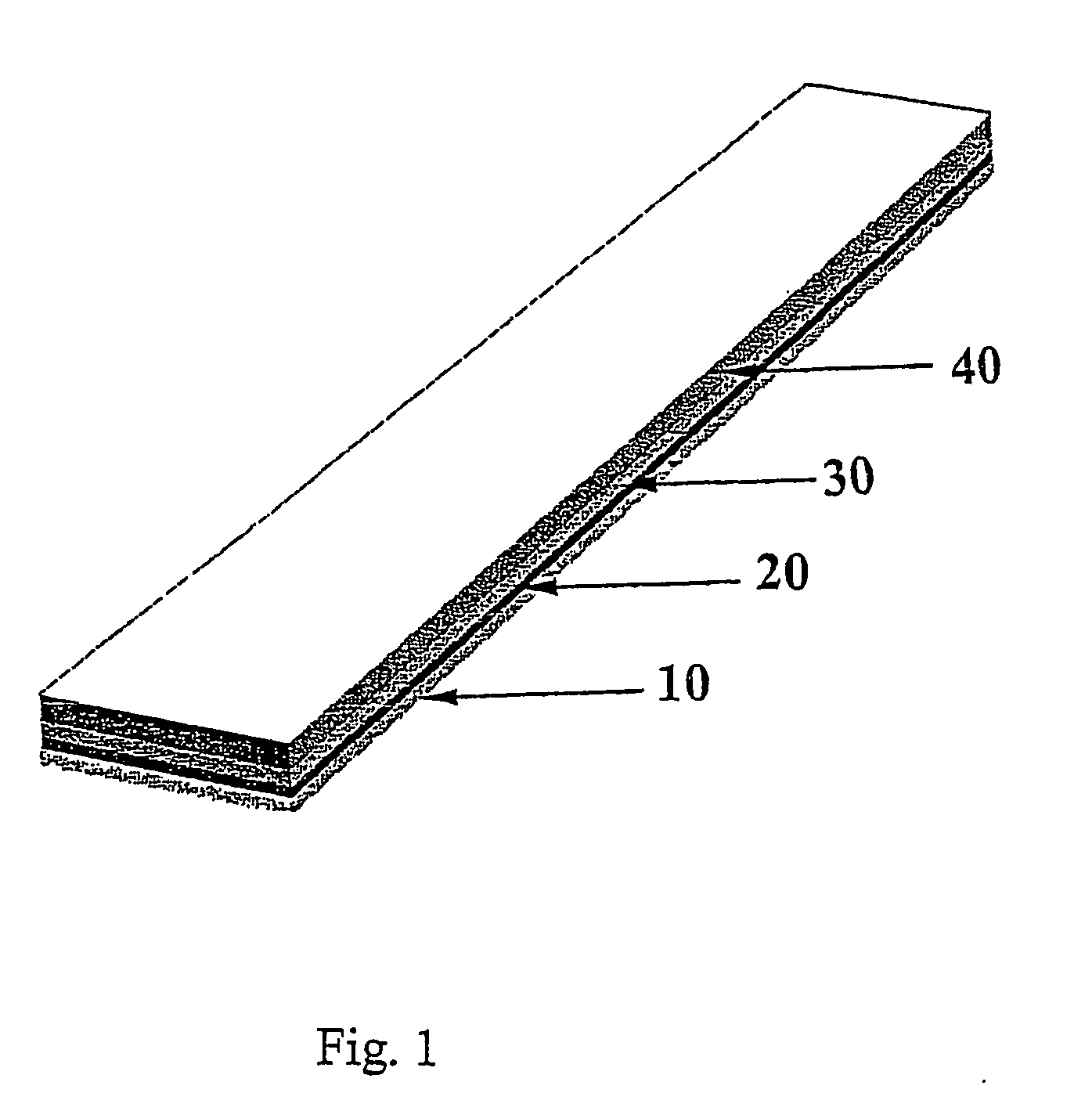

Image

Examples

example 1

[0021] Manufacture of coated base paper, coated with polyvinyl alcohol using a spray method Non-calendered paper Simkraft MF Specials having a grammage of 85 g / m2 and blade coating of 12.5 g / m2 was coated with a thin layer of polyvinyl alcohol by spray coating using a Helicoater device. Sample 1 was a reference sample not coated. In sample 2 polyvinyl alcohol Mowiol® having a degree of hydrolysis of 10 - 98, solid content of 5 %, viscosity of 64 cP, and the amount applicated being 1 g / m2 was used. In sample 3 polyvinyl alcohol Mowiol® having a degree of hydrolysis of 15 - 99, solid content of 5 %, viscosity of 27 cP, and the amount applicated being 1 g / m2 was used, and the same grade was used in sample 4, but then the solid content was 3 %, viscosity 18 cP, and amount applicated 0.5 g / m2. Pigment coating of the base paper was carried out as blade coating, followed by drying, then barrier layer coating using either spray coating or curtain coating, drying, and optional calendaring, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com