Highly-resistant-to-water core-level glass fiber air filtering paper and preparing method

A technology of air filter paper and glass fiber, which is applied in pulp beating method, filter paper, filtration separation, etc., can solve the problems of insufficient water resistance and short water resistance time, and achieve good filtering effect, smooth surface and good film formation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

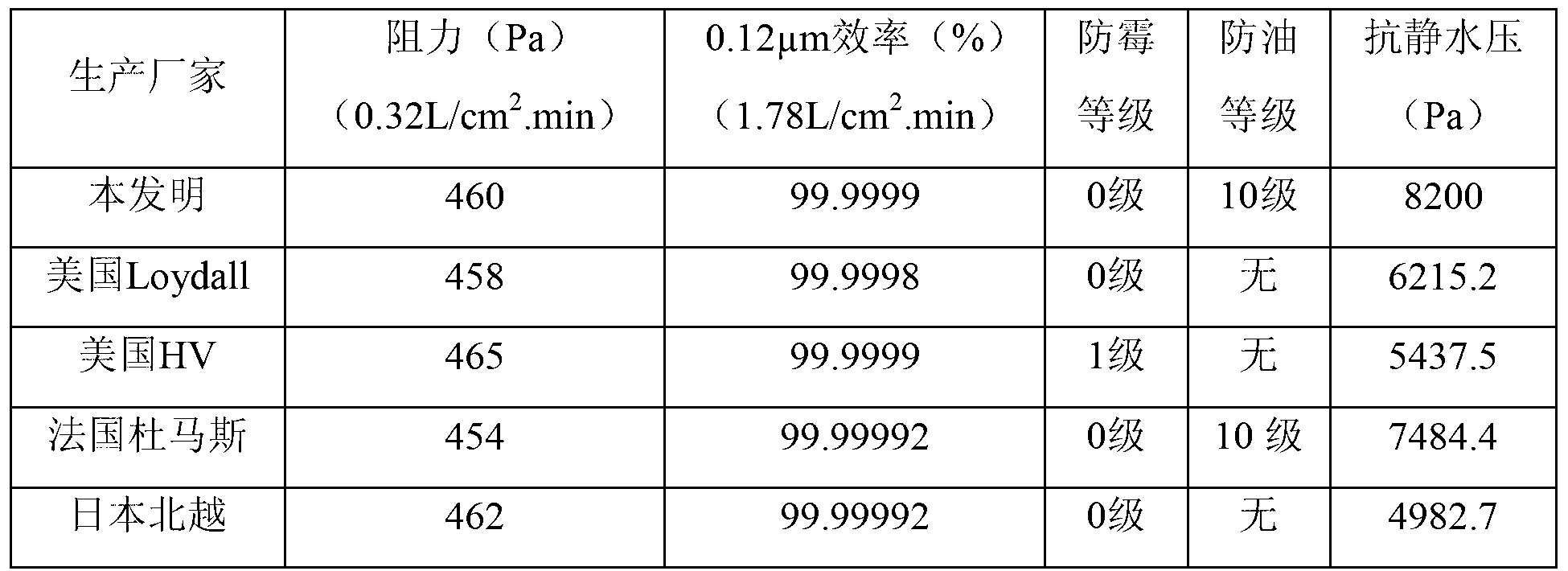

Image

Examples

Embodiment 1

[0023] The method that present embodiment prepares high anti-water nuclear grade glass fiber air filter paper comprises the following steps:

[0024] 1) Select 28 parts of alkali-free glass fiber with a diameter of 0.1 μm, 52 parts of alkali-free glass fiber with a diameter of 0.5 μm, 15 parts of alkali-free glass fiber with a diameter of 0.8 μm, and 5 parts of long alkali-free glass fiber with a diameter of 1.5 μm share;

[0025] 2) Add the selected raw materials into the sulfuric acid aqueous solution to beat and disperse to obtain a slurry, control the mass concentration of the slurry to 3%, the degree of beating to 48°SR, the pH value to 2.8, and the beating time to 30 minutes;

[0026] 3) Add water to dilute the slurry obtained in step 2) to a mass concentration of 0.3%;

[0027] 4) Use a centrifugal deslagging machine to remove slag from the diluted slurry in step 3), and perform wet molding on an inclined wire forming paper machine to obtain glass fiber wet paper;

[...

Embodiment 2

[0032] The method that present embodiment prepares high anti-water nuclear grade glass fiber air filter paper comprises the following steps:

[0033] 1) Select 20 parts of E-glass fiber with a diameter of 0.3 μm, 57 parts of E-glass fiber with a diameter of 0.7 μm, 15 parts of E-glass fiber with a diameter of 1.0 μm, and 8 long fibers of E-glass with a diameter of 1.5 μm share;

[0034] 2) Add the selected raw materials into the sulfuric acid aqueous solution to beat and disperse to obtain a slurry, control the mass concentration of the slurry to 3%, the degree of beating to 48°SR, the pH value to 2.8, and the beating time to 30 minutes;

[0035] 3) Add water to dilute the slurry obtained in step 2) to a mass concentration of 0.3%;

[0036] 4) Use a centrifugal deslagging machine to remove slag from the diluted slurry in step 3), and perform wet molding on an inclined wire forming paper machine to obtain glass fiber wet paper;

[0037] 5) The wet paper obtained in the dehydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com