Method for recovering alkylene oxide

A technology of alkylene oxide and recovery method, which is applied in the direction of organic chemistry, can solve the problems of ineffective recycling of alkylene oxide, achieve the effect of solving the problem of VOCs emission, reducing the content of alkylene oxide, and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

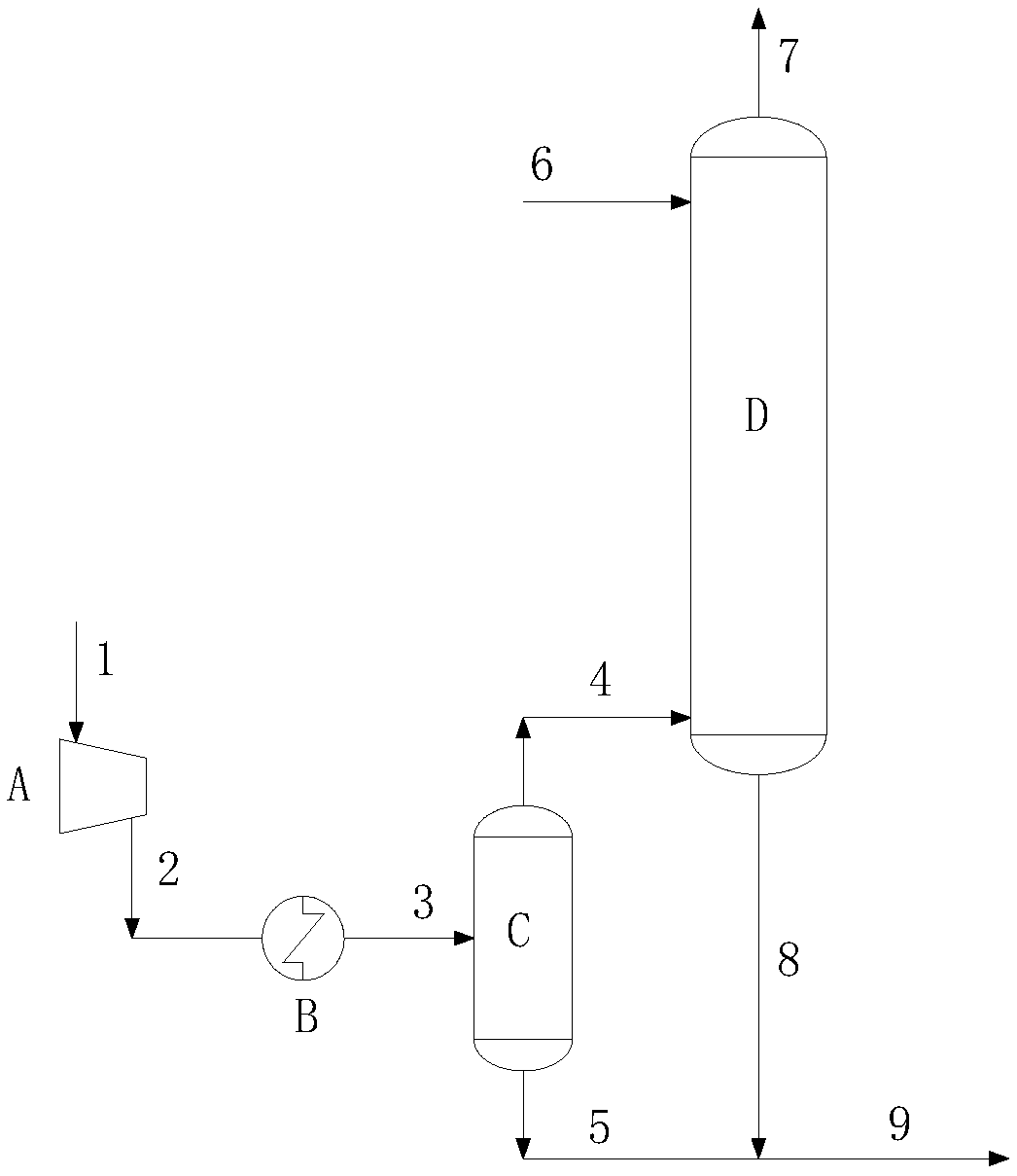

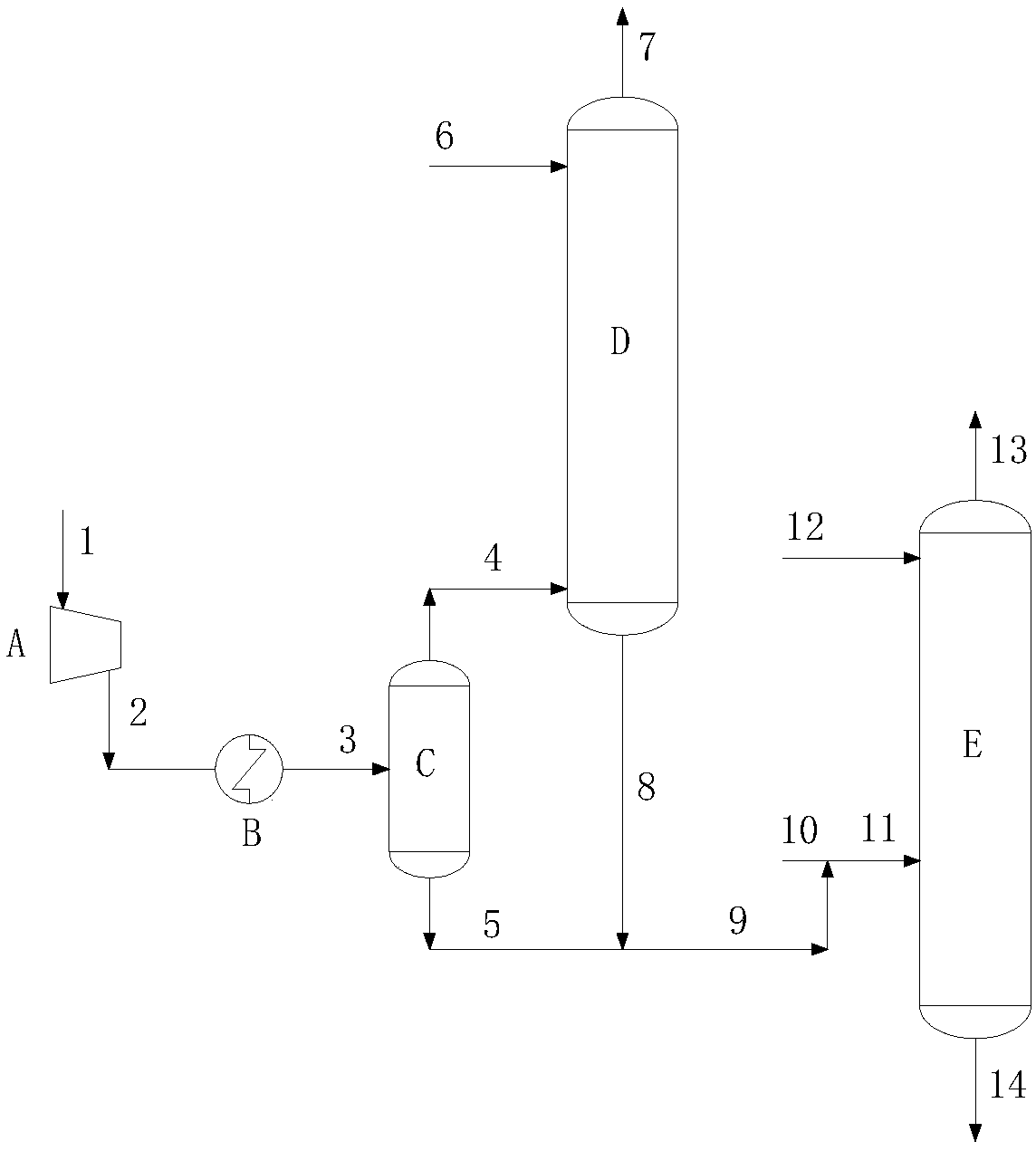

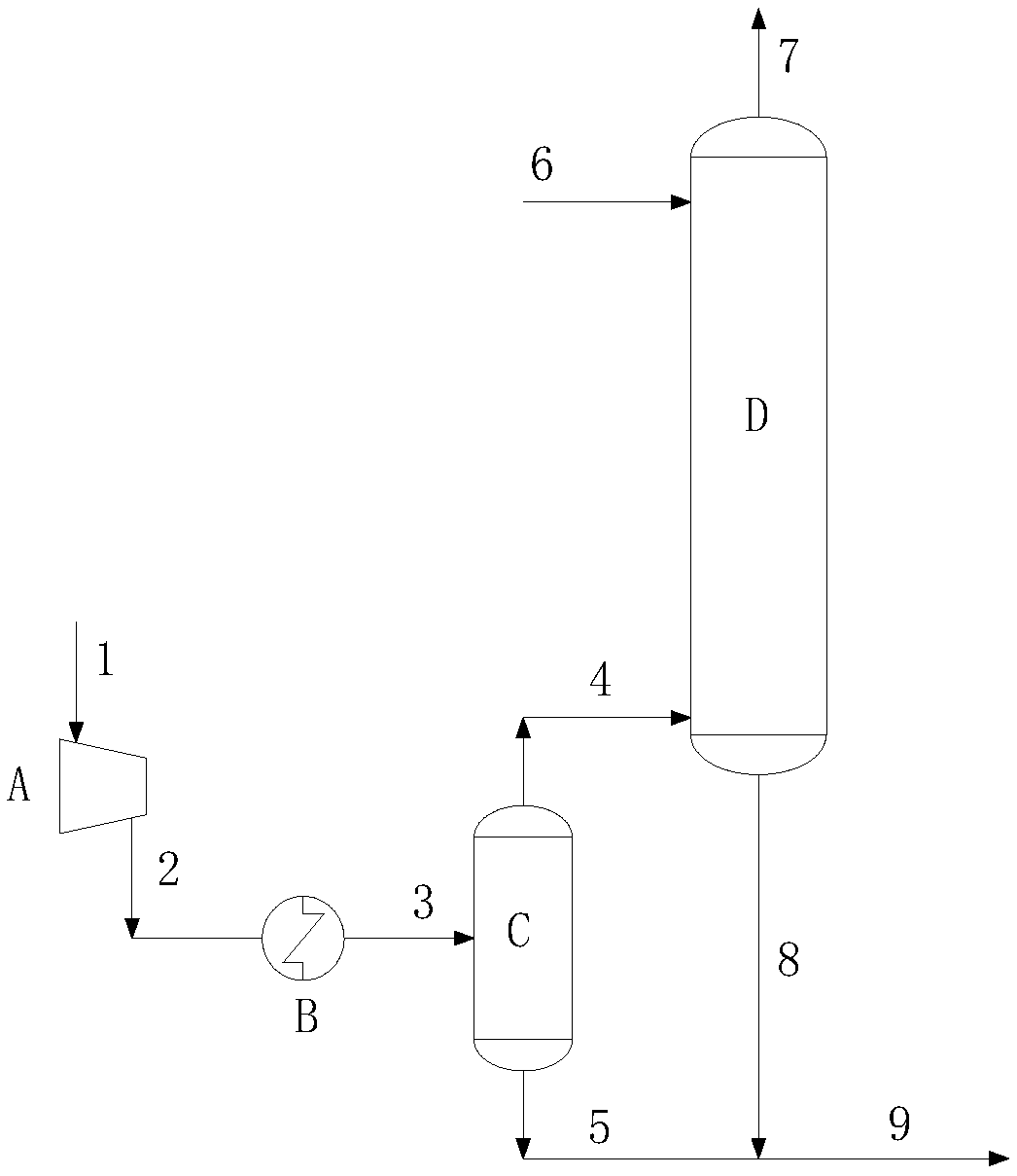

[0048] Such as figure 1 , shown in 2, by sending tail gas (1) containing propylene oxide, nitrogen, water, acetaldehyde into compressor A, after pressurization (2), it enters cooler B for cooling, and cooling liquid (3) enters gas-liquid separation After the gas-liquid separation of device C, the gas phase (4) enters from the bottom of the absorption tower D, the cold extractant (6) enters from the middle and upper part of the tower, the gas phase (7) on the top of the absorption tower is removed from the torch and other post-treatments, and the liquid phase of the tower kettle (8 ) and the liquid phase (5) at the bottom of the gas-liquid separator (9) are sent to the middle and lower part of the extractive distillation tower E of the propylene oxide refining unit, and the extractant feed is fed to the top of the extractive distillation tower E (12) feed, and 13 is the extraction The middle and upper product of rectification tower E tower, 14 is the bottom product of extractiv...

Embodiment 2

[0059] With embodiment 1, cold extraction agent (6) enters from tower top, and the molar composition of the tail gas containing propylene oxide, nitrogen, water, acetaldehyde etc. is 50% of propylene oxide, water 50ppm, acetaldehyde 10ppm, and remaining composition Divided into nitrogen. The outlet pressure of the compressor is 0.40MPaG.

[0060] The outlet temperature of the cooler was 10°C.

[0061] The ratio of the amount of extraction agent added to the gas phase feed amount of the absorption tower tank is 2:1.

[0062] The operating pressure of the gas-liquid separator is 0.38MPaG.

[0063] The operation mode of the gas-liquid separator is adiabatic flash evaporation, and the heat load is 0.

[0064] The operating pressure of the absorption tower is 0.36MPaG.

[0065] The number of theoretical plates of the absorption tower is 5.

[0066] The absorbent is the same as the extractant of the propylene oxide refining unit, both are n-octane, and the feed temperature of t...

Embodiment 3

[0069] With embodiment 1, cold extraction agent (6) enters from tower top, and the molar composition of the tail gas that contains propylene oxide, nitrogen, water, acetaldehyde etc. is propylene oxide 50%, water 50ppm, acetaldehyde 10ppm, remaining composition Divided into nitrogen. The outlet pressure of the compressor is 0.40MPaG.

[0070] The outlet temperature of the cooler was 10°C.

[0071] The ratio of the amount of extraction agent added to the gas phase feed amount of the absorption tower tank is 2:1.

[0072] The operating pressure of the gas-liquid separator is 0.38MPaG.

[0073] The operation mode of the gas-liquid separator is adiabatic flash evaporation, and the heat load is 0.

[0074] The operating pressure of the absorption tower is 0.36MPaG.

[0075] The number of theoretical plates of the absorption tower is 15.

[0076] The absorbent is the same as the extractant of the propylene oxide refining unit, both are n-octane, and the feed temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com