Preparation method of common yam rhizome beer

A technology of yam and beer, applied in the field of fermentation processing, can solve the problems of affecting product quality, reducing refreshing taste, high viscosity of beverages, etc., and achieve the effect of enhancing antioxidant capacity, helping the full taste and high fermentation power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

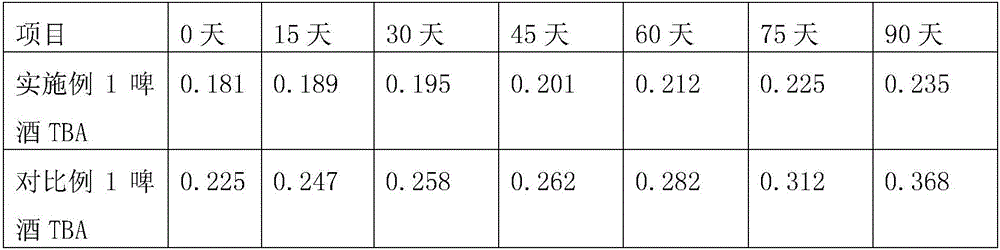

Examples

Embodiment 1

[0039] A preparation method of yam beer, the steps are as follows:

[0040] 1) Raw material processing: humidify and crush the malt, break the skin of the malt after crushing, the skin is broken but not broken; wash and peel the fresh yam, dig out the black spots, cut it into sections, put it into a beater for beating, and carry out coarse crushing; The coarse slurry material is poured into the colloid mill for refining treatment, and the slurry is passed through a 200-mesh sieve to make yam slurry;

[0041] 2) Saccharification: Take the pure water after reverse osmosis treatment, add gypsum to the pure water after reverse osmosis treatment to adjust the calcium ion concentration to 80mg / L, heat to 38°C, add step 1) yam slurry and crushed malt , mix evenly, keep the temperature of the mixed mash at 40°C for acid rest, the time is 15min, the weight ratio of the crushed malt and yam slurry is 90:5, the mass ratio of the amount of crushed malt and yam slurry to water is 1 :4. T...

Embodiment 2

[0057] A preparation method of yam beer, the steps are as follows:

[0058] 1) Raw material processing: humidify and crush the malt, break the skin of the malt after crushing, the skin is broken but not broken; wash and peel the fresh yam, dig out the black spots, cut it into sections, put it into a beater for beating, and carry out coarse crushing; The coarse slurry material is poured into the colloid mill for refining treatment, and the slurry is passed through a 200-mesh sieve to make yam slurry;

[0059] 2) Saccharification: Take the pure water after reverse osmosis treatment, add gypsum to the pure water after reverse osmosis treatment to adjust the calcium ion concentration to 90mg / L, heat to 40°C, add step 1) yam slurry and crushed malt , mix evenly, keep the temperature of the mixed mash at 40°C for acid rest, the time is 10min, the weight ratio of the crushed malt and yam slurry is 92:8, the mass ratio of the amount of crushed malt and yam slurry to water is 1 :3.6. ...

Embodiment 3

[0066] A preparation method of yam beer, the steps are as follows:

[0067] 1) Raw material processing: malt is humidified and crushed, and the malt is crushed to break the skin, and the skin is broken but not broken; the dried yam is crushed into yam powder, passed through a 200-mesh sieve, and set aside;

[0068] 2) Saccharification: take the reverse osmosis treated pure water, add gypsum to the reverse osmosis treated pure water to adjust the calcium ion concentration to 100mg / L, heat to 42°C, add step 1) yam powder and crushed malt , mix evenly, keep the temperature of the mixed mash at 40°C for acid rest, the time is 20min, the weight ratio of crushed malt and yam powder is 95:10, the mass ratio of the amount of crushed malt and yam powder to water is 1 :4. Then raise the temperature to 50°C for proteolysis, the protein decomposition time is 40min, control the a-N content of wort to 170-180mg / L, then first raise the temperature to 65°C and keep it for 30 minutes; then ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com