Method for inhibiting polymerization of acetaldehyde in polyvinyl alcohol and vinyl acetate production process

A vinyl acetate and polyvinyl alcohol technology, applied in the chemical industry, can solve the problems of easy decomposition, hydrolysis of vinyl acetate, affecting the quality of vinyl acetate, etc., and achieves the effects of good polymerization inhibition effect, reducing acetaldehyde content, and improving the purity of refined acetaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

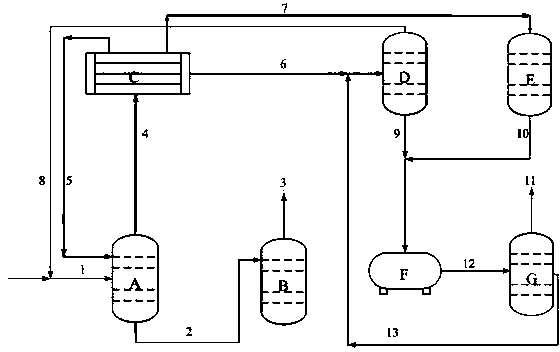

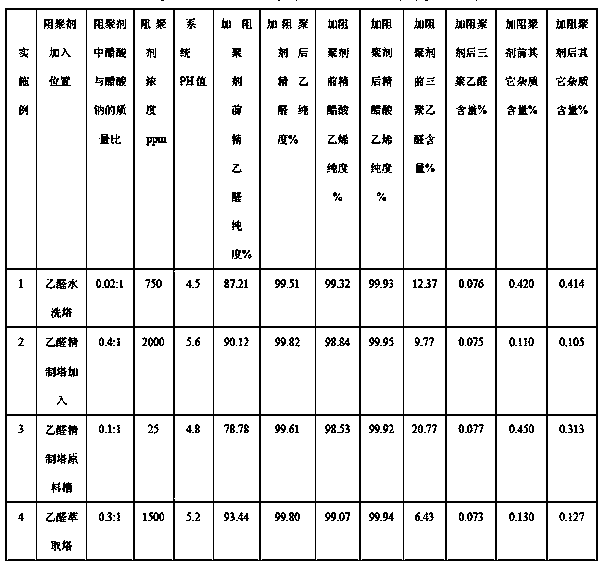

[0025] Acetaldehyde refining and recovery process: refer to figure 1 As shown in the process flow diagram, the reaction liquid of vinyl acetate 1 containing acetaldehyde enters the dealdehyde tower A, and the vinyl acetate and acetic acid in the tower A of the dealdehyde tower A enter into the vinyl acetate refining tower B to obtain refined vinyl acetate 3, and the top of the dealdehyde tower A The distilled vinyl acetate and acetaldehyde gas 4 enters the partial condenser C, part of the condensate of vinyl acetate and acetaldehyde returns to the dealdehyde tower A, part of the vinyl acetate and acetaldehyde 6 enters the acetaldehyde extraction tower D, and the acetaldehyde extraction tower D The raffinate 8 returns to the dealdehyde tower A, the uncondensed gas 7 containing acetylene and a small amount of acetaldehyde in the upper part of the partial condenser C enters the acetaldehyde washing tower E, and the extract 9 containing a small amount of vinyl acetate in the acetal...

Embodiment 2

[0029] refer to figure 1 The process flow shown is the same as in Example 1, except that the polymerization inhibitor is added twice from the acetaldehyde refining tower G (intermittent 3 hours) to the refining and recovery system, and the mass ratio of acetic acid to sodium acetate is 0.4 : 1, the addition concentration is 2000ppm, and the pH value of the acetaldehyde aqueous solution in the regulation system is 5.6.

[0030] Effect: Before adding inhibitor, the mass percentage of paraldehyde distilled from acetaldehyde refining tower G is 9.77%, the purity of refined acetaldehyde is 90.12%, and the content of other impurities is 0.110%. The purity of refined vinyl acetate distilled from vinyl acetate refining tower B is 98.84%; after adding the polymerization inhibitor, the mass percentage of paraldehyde distilled from acetaldehyde refining tower G is 0.075%, and the purity of refined acetaldehyde is 99.82%. The content of other impurities is 0.105%. The purity of the refi...

Embodiment 3

[0032] refer to figure 1 The shown process flow is the same as in Example 1, except that the polymerization inhibitor is added in twice from the raw material tank F of the acetaldehyde refining tower (intermittent 3 hours) to the refining and recovery system, and the mass ratio of acetic acid to sodium acetate is 0.1:1, the added concentration is 25ppm, and the pH value of the acetaldehyde aqueous solution in the adjustment system is 4.8.

[0033] Effect: Before adding inhibitor, the mass percentage of paraldehyde distilled from acetaldehyde refining tower G is 20.77%, the purity of refined acetaldehyde is 78.78%, and the content of other impurities is 0.450%. The purity of refined vinyl acetate distilled from vinyl acetate refining tower B is 98.53%; after adding the polymerization inhibitor, the mass percentage of paraldehyde distilled from acetaldehyde refining tower G is 0.077%, and the purity of refined acetaldehyde is 99.61%. The content of other impurities is 0.313%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com