A kind of low-voc polypropylene material and its preparation method and application

A polypropylene material and polypropylene technology, applied in the field of modified polypropylene material, low-VOC, low-acetaldehyde polypropylene material and its preparation, can solve problems such as no solution, and achieve the effect of reducing acetaldehyde content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

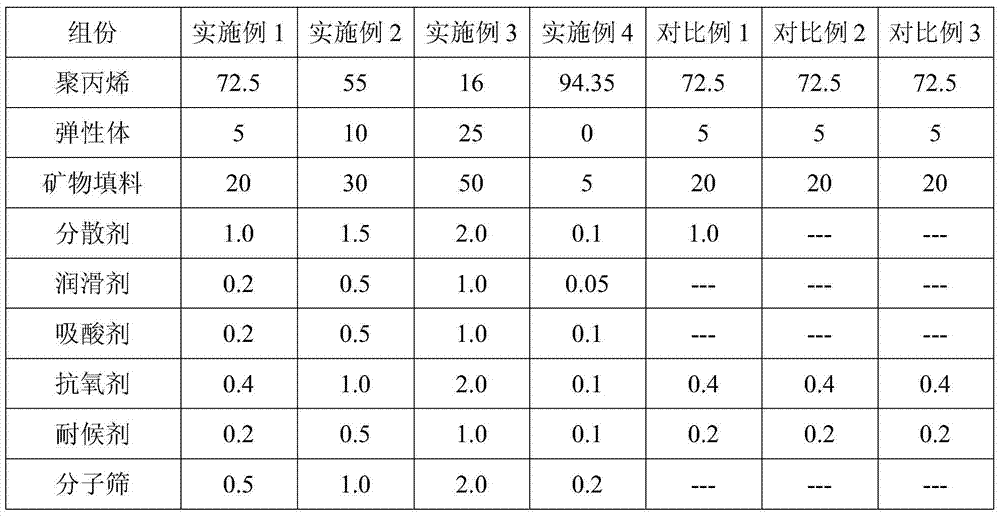

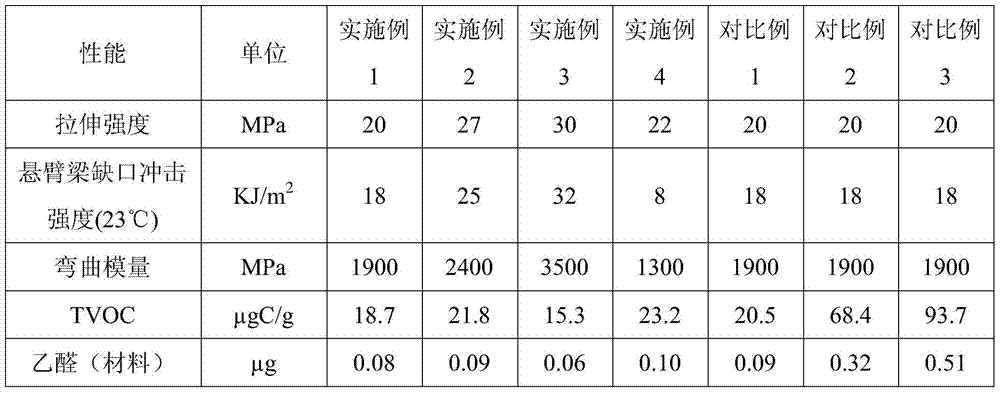

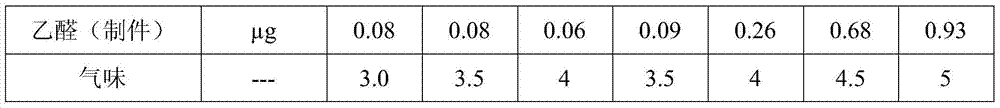

Embodiment 1

[0046] A kind of low-VOC polypropylene material, its raw material formula is shown in Table 1, and its preparation method comprises the following steps:

[0047] Add polypropylene, elastomer and dispersant to a low-speed mixer and mix evenly, with a rotation speed of ≤80r / min; then add mineral fillers, lubricants, acid absorbers, antioxidants, and weather-resistant agents for mixing, and finally add molecular sieves. After mixing evenly, add it from the main feeding port of the twin-screw extruder, carry out melt blending, vacuum extrude through the extruder, dry, granulate and classify with the granulator to obtain the low-VOC polypropylene material.

[0048] The aspect ratio of the twin-screw extruder is 48:1, and the temperature of the melting section of the twin-screw extruder is 180°C.

[0049] Among them, the polypropylene used is homopolypropylene, the elastomer is ethylene-butylene copolymer, the dispersant is acetone, the mineral filler is talcum powder, the lubricant...

Embodiment 2

[0051] A kind of low-VOC polypropylene material, its raw material formula is shown in Table 1, and its preparation method is with embodiment 1;

[0052] The aspect ratio of the twin-screw extruder is 48:1, and the temperature of the melting section of the twin-screw extruder is 210°C.

[0053] Among them, the polypropylene used is copolymerized polypropylene, the elastomer is ethylene-hexene copolymer, the dispersant is purified water, the mineral filler is talcum powder, the lubricant is C22 unsaturated aliphatic amide, and the acid absorber is stearic acid A compound of zinc and magnesium oxide in a mass ratio of 1:2, and the antioxidants are hindered phenolic antioxidants (antioxidant 3114) and phosphite antioxidants (antioxidant 168) at a ratio of 1:1 The mass ratio composition, the weather resistance agent is a hindered amine light stabilizer (Chimassorb 944); the molecular sieve is a hydrophobic zeolite molecular sieve with a pore size of 0.2-1 nanometer.

Embodiment 3

[0055] A kind of low-VOC polypropylene material, its raw material formula is shown in Table 1, and its preparation method is with embodiment 1;

[0056] The aspect ratio of the twin-screw extruder is 52:1, and the temperature of the melting section of the twin-screw extruder is 230°C.

[0057] Among them, the polypropylene used is homopolypropylene, the elastomer is ethylene-octene copolymer, the dispersant is a mixture of acetone and purified water at a mass ratio of 1:1, the mineral filler is talcum powder, and the lubricant is C25. Saturated aliphatic amide, the acid absorbing agent is a compound of zinc stearate and zinc oxide at a mass ratio of 1:3, the antioxidant is hindered phenolic antioxidant (antioxidant 1076), phosphite antioxidant The oxygen agent (antioxidant 626) is composed at a mass ratio of 1:1, and the weather resistance agent is a hindered amine light stabilizer (Tinuvin 770); the molecular sieve is a hydrophobic zeolite molecular sieve with a pore size of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com