Acetic acid production wastewater treatment process

A technology for the production of waste water and treatment process, which is applied in the direction of natural water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of high cost, inability to recycle acetaldehyde and iodine resources, etc., to improve production Efficiency, reduction of processing costs, and improvement of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

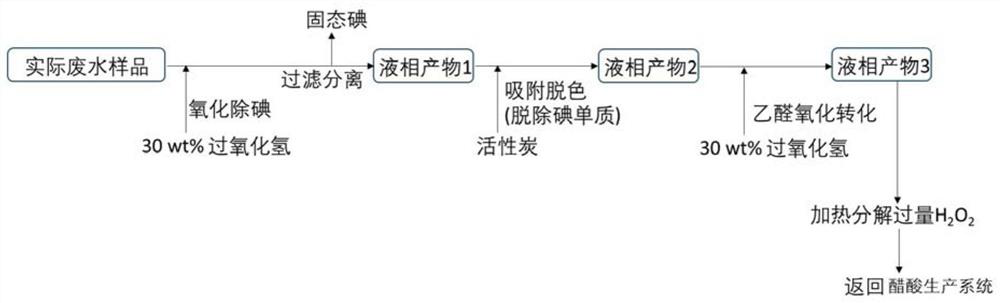

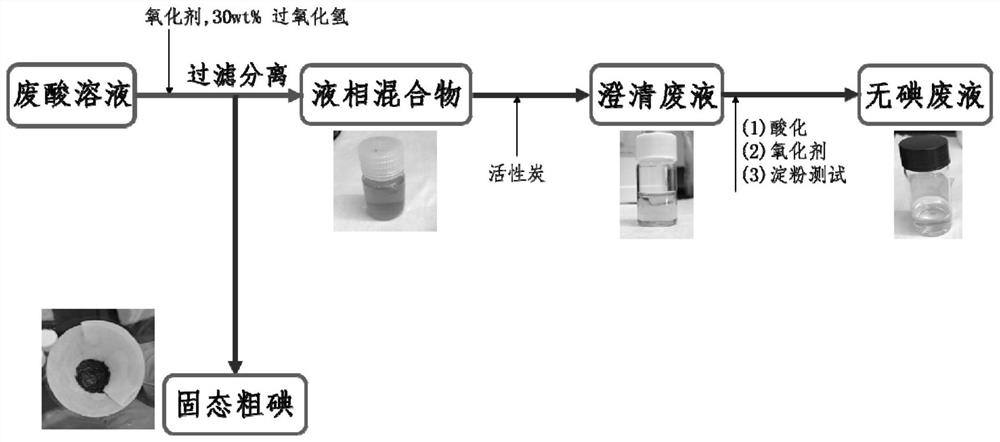

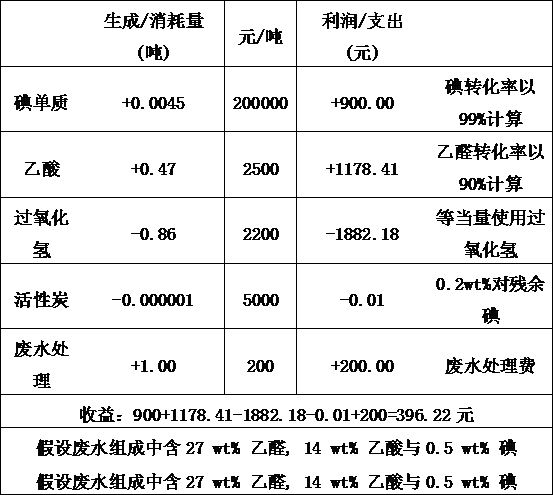

[0024] A kind of acetic acid production wastewater treatment process, it comprises the following steps:

[0025] S1 adds 30 wt% hydrogen peroxide aqueous solution to acetic acid production wastewater, wherein the molar equivalent ratio of hydrogen peroxide and iodine in wastewater is 1:1, hydrogen peroxide reacts with iodide ions in wastewater to generate iodine simple substance, and reacts in normal Under pressure, the reaction temperature is 15°C, and the reaction time is 60 minutes;

[0026] S2 filters the mixture that has been reacted in step S1, and separates the solid iodine elemental substance generated by the reaction from the waste water, and the remaining liquid is the liquid phase product 1;

[0027] S3 adds activated carbon powder in liquid phase product 1 after step S2 is processed, and the mass ratio of the activated carbon added and the residual iodine in liquid phase product 1 is 1:1000;

[0028] S4 filters the liquid phase product 1 after the treatment in ste...

Embodiment 2

[0031] A kind of acetic acid production wastewater treatment process, it comprises the following steps:

[0032] S1 Add 30 wt% hydrogen peroxide aqueous solution to acetic acid production wastewater, wherein the molar equivalent ratio of hydrogen peroxide to iodine in wastewater is 2:1, hydrogen peroxide reacts with iodide ions in wastewater to generate iodine element, the reaction is in normal Under pressure, the reaction temperature is 30°C, and the reaction time is 20 minutes;

[0033] S2 carries out gravity filtration or decompression filtration to the reaction mixture of step S1, and the solid iodine simple substance generated by the reaction is separated from the waste water, and the remaining liquid is liquid phase product 1;

[0034] S3 adds gac powder in the liquid phase product 1 after step S2 is processed, and the mass ratio of the gac added and the iodine remaining in the liquid phase product 1 is 1:500;

[0035] S4 performs gravity filtration or vacuum filtration...

Embodiment 3

[0038] A kind of acetic acid production wastewater treatment process, it comprises the following steps:

[0039] S1 adds 40 wt% hydrogen peroxide aqueous solution to the acetic acid production wastewater, wherein the molar equivalent ratio of hydrogen peroxide and iodine in the wastewater is 3:1, and hydrogen peroxide reacts with iodide ions in the wastewater to generate iodine element, which reacts in normal Under pressure, the reaction temperature is 60°C, and the reaction time is 5 minutes;

[0040] S2 filters the mixture that has been reacted in step S1, and separates the solid iodine elemental substance generated by the reaction from the waste water, and the remaining liquid is liquid phase product 1;

[0041] S3 adds activated carbon powder in the liquid phase product 1 after step S2 is processed, the mass ratio of the activated carbon added and the iodine remaining in the liquid phase product 1 is 1:100;

[0042] S4 filters the liquid phase product 1 treated in step S3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com