Copolyester and polyester bottle made of same

A technology of copolyester and polyester, applied in the field of copolyester, can solve the problems of high manufacturing cost and increased commercialization resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

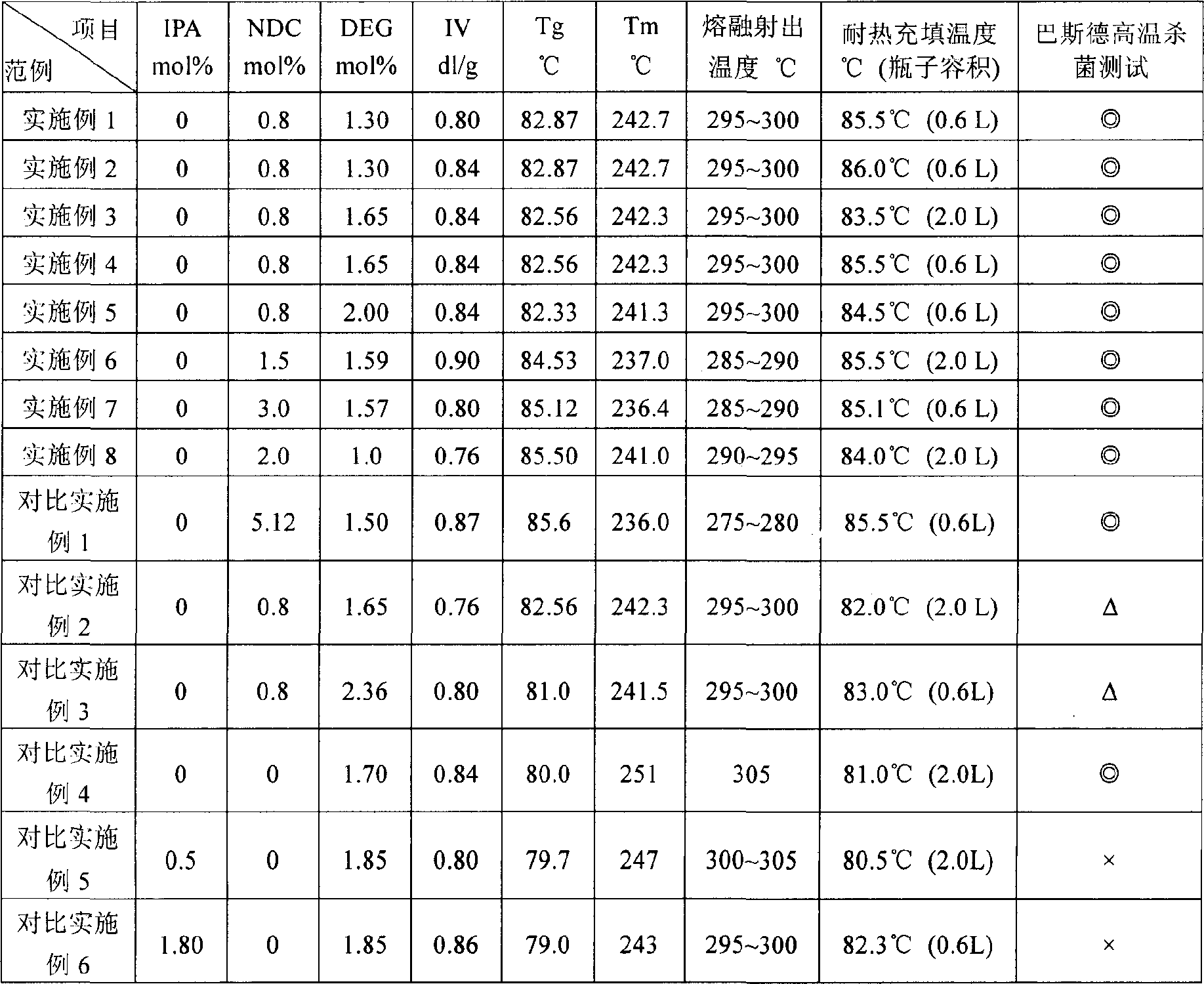

[0044] According to the preparation method of the copolyester containing naphthalene ring structure shown in the present invention, obtain the copolyester containing 0.8 mol % 2,6-naphthalene dicarboxylate and 1.30 mol % diethylene glycol based on the copolyester, and this The intrinsic viscosity of the copolyester was 0.80 dl / g.

[0045] As shown in Table 1, this copolyester is used to make a polyester filling bottle with a capacity of 0.6 liters. After testing, the heat-resistant filling temperature is 85.5°C, and it can pass the Pasteur high temperature sterilization test.

Embodiment 2

[0047] The copolyester obtained in Example 1 is used as the material, but the intrinsic viscosity of the copolyester is increased to 0.84dl / g.

[0048] As shown in Table 1, the polyester filled bottle with a capacity of 0.6 liters made of this copolyester has a heat-resistant filling temperature of 86.0° C. and can pass the Pasteur high temperature sterilization test.

Embodiment 3

[0050] According to the preparation method of the copolyester containing naphthalene ring structure shown in the present invention, obtain the copolyester containing 0.8 mol % 2,6-naphthalene dicarboxylate and 1.65 mol % diethylene glycol based on the copolyester, and this The intrinsic viscosity of the copolyester was 0.84 dl / g.

[0051] As shown in Table 1, a polyester filled bottle with a capacity of 2.0 liters made of this copolyester has a heat-resistant filling temperature of 83.5° C. and can pass the Pasteur high temperature sterilization test.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com