Polyacrylate-modified polyurethane aqueous coating emulsion with high water pressure resistance and preparation method thereof

A technology of polyacrylate and polyurethane, which is applied in the direction of textiles, papermaking, and fiber treatment, etc. It can solve the problem of unsatisfactory hand feel, cold resistance, fastness, water pressure, unsatisfactory comprehensive performance of polyacrylate emulsion, solvent resistance, poor cold resistance, etc. problems, to achieve the effect of good bonding fastness, increased rigidity, and good washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

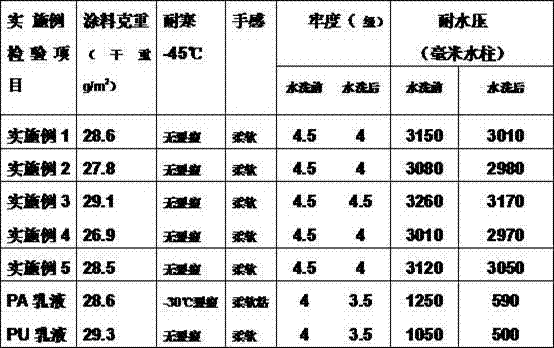

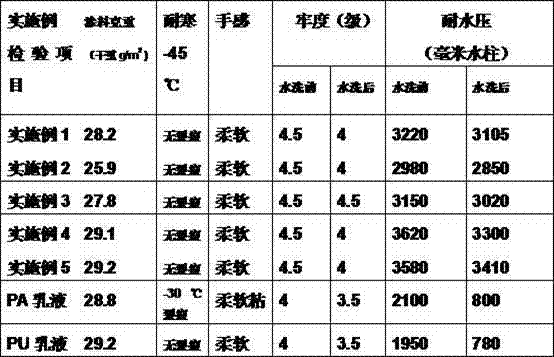

Examples

Embodiment 1

[0030] Raw material weight ratio:

[0031] (A) isophorone diisocyanate (IPDI) 50, (B) dimethylol butyric acid (DMBA) 6, (C) polybutadiene diol (molecular weight 2000) 40, (D) neopentyl diol Alcohol 6, (E) isophorone diamine 6, (F) triethylamine 4, (G) deionized water 311, (H) styrene 15, (I) butyl acrylate 50, (J) methyl Hydroxyethyl acrylate 3, (K) ammonium persulfate 0.5;

[0032] Preparation:

[0033] Add isophorone diisocyanate (A), dimethylol butyric acid (B), polybutadiene diol (C) and neopentyl glycol (D) into the reaction kettle, and heat up to 70-100°C for reaction 3 hours, then after cooling down to 40-60°C, add butyl acrylate (I), styrene (H), hydroxyethyl methacrylate (J), and keep stirring at 40-60°C for 1 hour, then add three React ethylamine (F) at 40-60°C for 0.5-1 hour, add deionized water (G) to disperse at high speed for 20 minutes, add isophorone diamine (E) and react at 40-60°C for 2-3 hours, then heat up Start to titrate the aqueous solution o...

Embodiment 2

[0036] Raw material weight ratio: (A) isophorone diisocyanate (IPDI) 70, (B) dimethylol butyric acid (DMBA) 7, (C) polybutadiene diol (molecular weight 3000) 50, ( D) neopentyl glycol 6, (E) isophorone diamine 8, (F) triethylamine 4.8, (G) deionized water 240, (H) styrene 30, (I) butyl acrylate 40, (J) hydroxyethyl methacrylate 5, (K) potassium persulfate 0.8; the preparation method is the same as in Example 1, and the product is obtained.

[0037] The product of this embodiment has high water pressure resistance and good washing resistance due to the large amount of styrene in the raw material ratio.

Embodiment 3

[0039] Raw material weight ratio: (A) isophorone diisocyanate (IPDI) 70, (B) dimethylol butyric acid (DMBA) 10, (C) polybutadiene diol (molecular weight 1000) 30, ( D) neopentyl glycol 6, (E) isophorone diamine 5.5, (F) triethylamine 6.8, (G) deionized water 231, (H) styrene 15, (I) butyl acrylate 50, (J) hydroxyethyl methacrylate 10, (K) potassium persulfate 0.5; the preparation method is the same as in Example 1 to obtain the product.

[0040] The product of this embodiment is due to the large amount of dimethylolbutyric acid in the raw material components, the product has strong hydrophilicity, good emulsion state, and good stability; the amount of hydroxyethyl methacrylate is large, and the degree of crosslinking is strengthened. best.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com