Coating fabric with high water pressure resistance and high moisture penetrability and preparation process thereof

A preparation process and water pressure resistance technology, which is applied in the direction of layered products, textile material processing, synthetic resin layered products, etc., can solve the problems of complex process and low water pressure resistance, achieve good wear resistance and reduce drainage Effect of resistance, high moisture permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

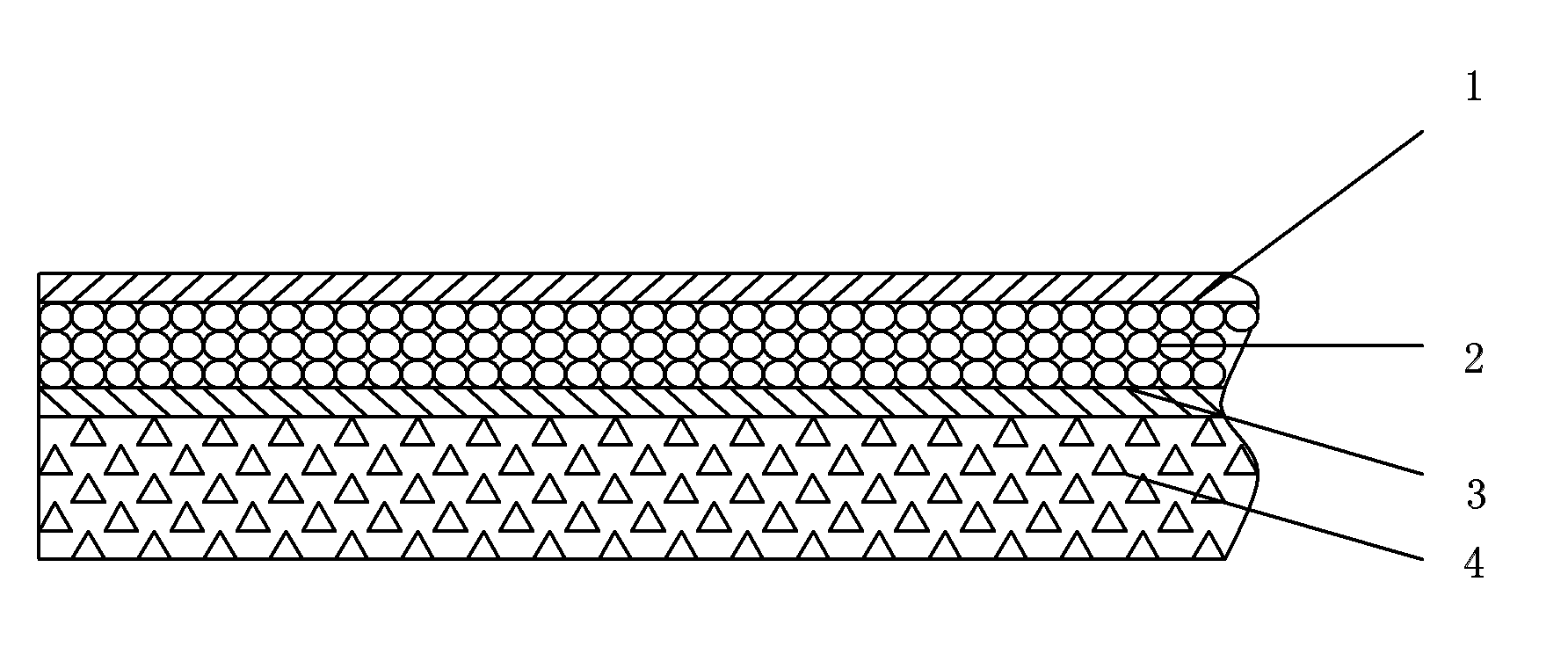

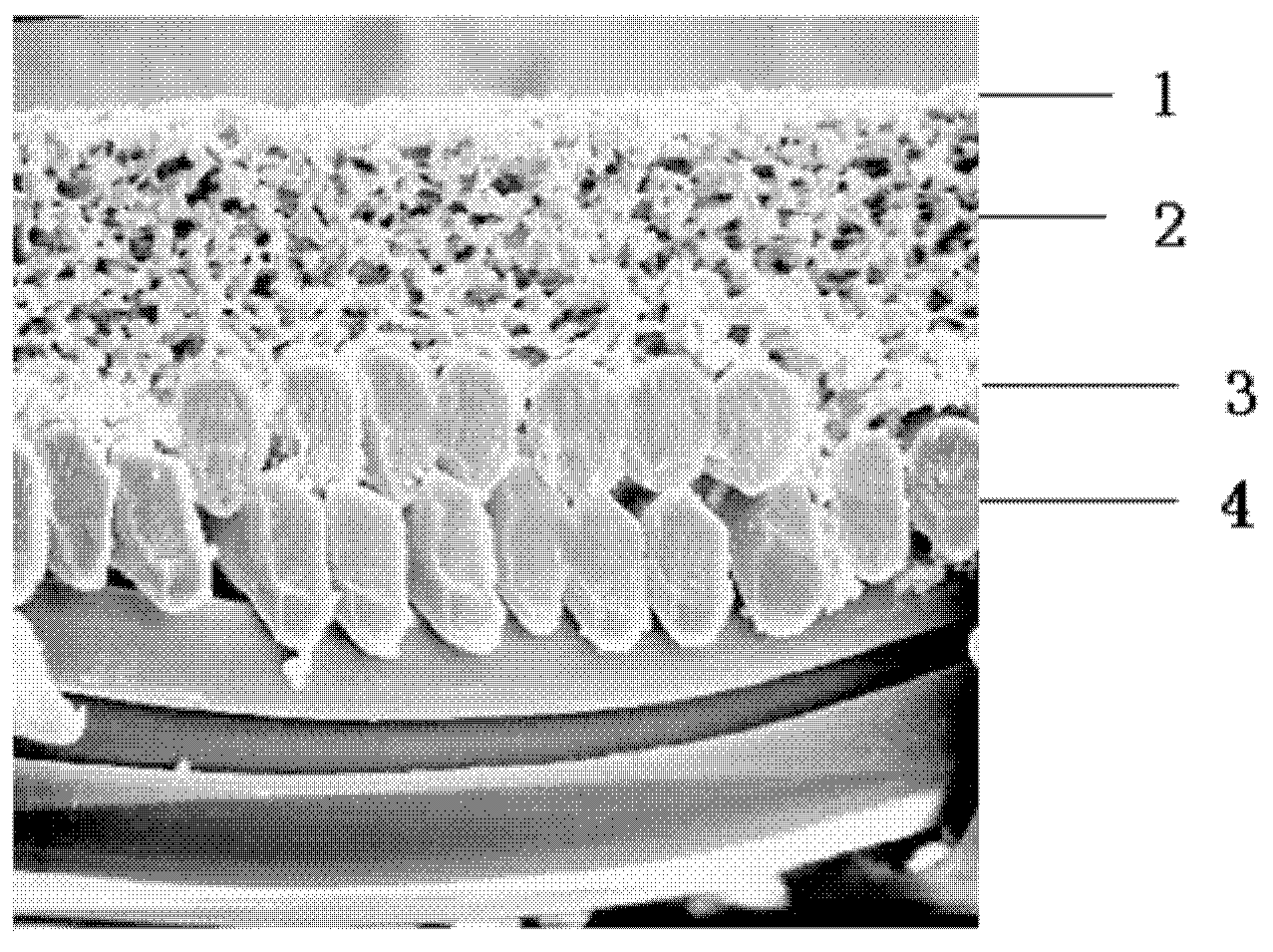

[0069] Such as figure 1 As shown, the high water pressure and high moisture permeability coating fabric of the present invention includes a load-bearing layer 4, a waterproof layer 3 coated on the load-bearing layer 4, and a microporous layer 2 coated on the waterproof layer 3, which is characterized in that : the coated fabric also includes a protective layer 1 coated on the microporous layer 2, and the protective layer 1 is a wear-resistant coating with a microporous structure.

[0070] The slurry of the waterproof layer 3 is: 83.3% of two-component polyether polyurethane, 12.5% of solvent, 2.5% of curing agent, and 1.7% of accelerator. The coating amount of the waterproof layer 3 is 4g / m in terms of solid content 2 .

[0071] Microporous layer 2 slurry contains 52.3% of aromatic polyether type polyurethane, butanone / toluene (12 / 24) 18.7%, trimer type polyisocyanate curing agent / polyfunctional group aziridine curing agent (5 parts by weight) / 1) 1.6%, defoamer / leveling...

Embodiment 2

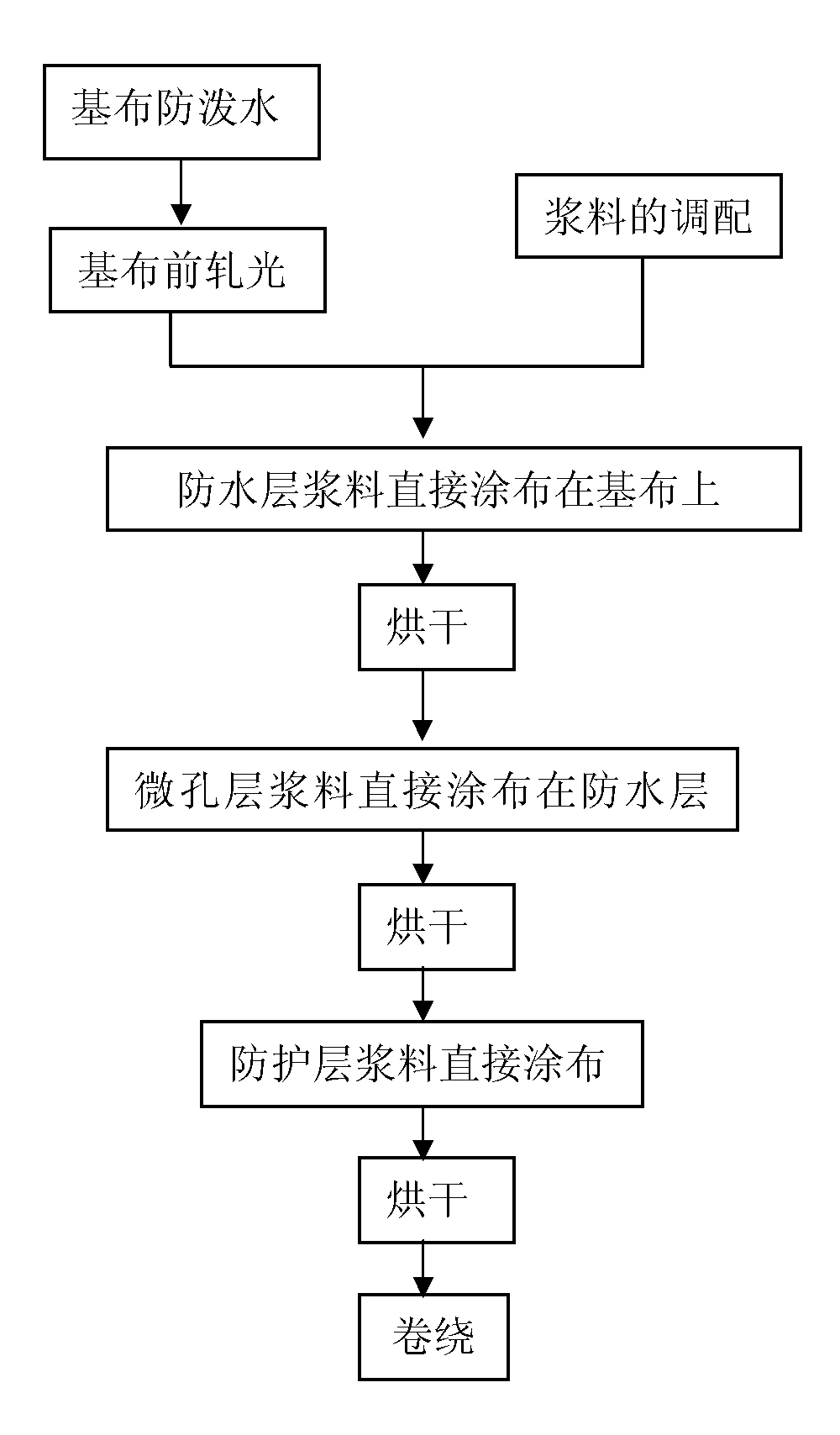

[0075] as attached image 3 As shown, the high water pressure and high moisture permeability coating fabric of the present invention is prepared by the following process:

[0076] 1. Use a water-repellent agent to treat pongee with water-repellent treatment;

[0077] 2. Carry out calendering treatment on the base fabric after water-repellent treatment;

[0078] 3. Prepare the waterproof layer 3 slurry, and apply the waterproof layer 3 slurry on the base fabric to form the waterproof layer 3;

[0079] 4. Drying of waterproof layer 3;

[0080] The drying of the waterproof layer 3 is carried out in three temperature zones, the temperature ranges of each temperature zone are 90°C, 120°C, and 150°C respectively, and the drying time of each temperature zone is 0.8 minutes.

[0081] 5. Coating the microporous waterproof and moisture-permeable slurry on the waterproof layer 3 to form the microporous layer 2;

[0082] a. The preparation of the microporous layer 2 slurry: the batchi...

Embodiment 3

[0092] Compared with Example 1, the differences are:

[0093] The base fabric is nylon spinning;

[0094] The content of the two-component polyether polyurethane in the slurry of the waterproof layer 3 is 80%; the coating amount of the waterproof layer 3 is 3g / m in terms of solid content 2 .

[0095] The microporous layer 2 slurry contains 45% of aromatic polyether polyurethane and 12% of acetone / toluene (12 / 24) by weight, and the coating amount of microporous layer 2 is calculated by solid content: 20g / m 2 .

[0096] The slurry of the protective layer 1 is: polyurethane 70%, MCC microporous agent 2%, and the coating amount of the protective layer 1 is 3g / m in terms of solid content 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com