tire

A tire and tire circumferential technology, applied in tire parts, tire tread/tread pattern, vehicle parts, etc., can solve the problems of deterioration of heel and toe wear, deterioration of tire wear life, etc. The effect of improving the anti-stone performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, one embodiment of the present invention will be described with reference to the drawings.

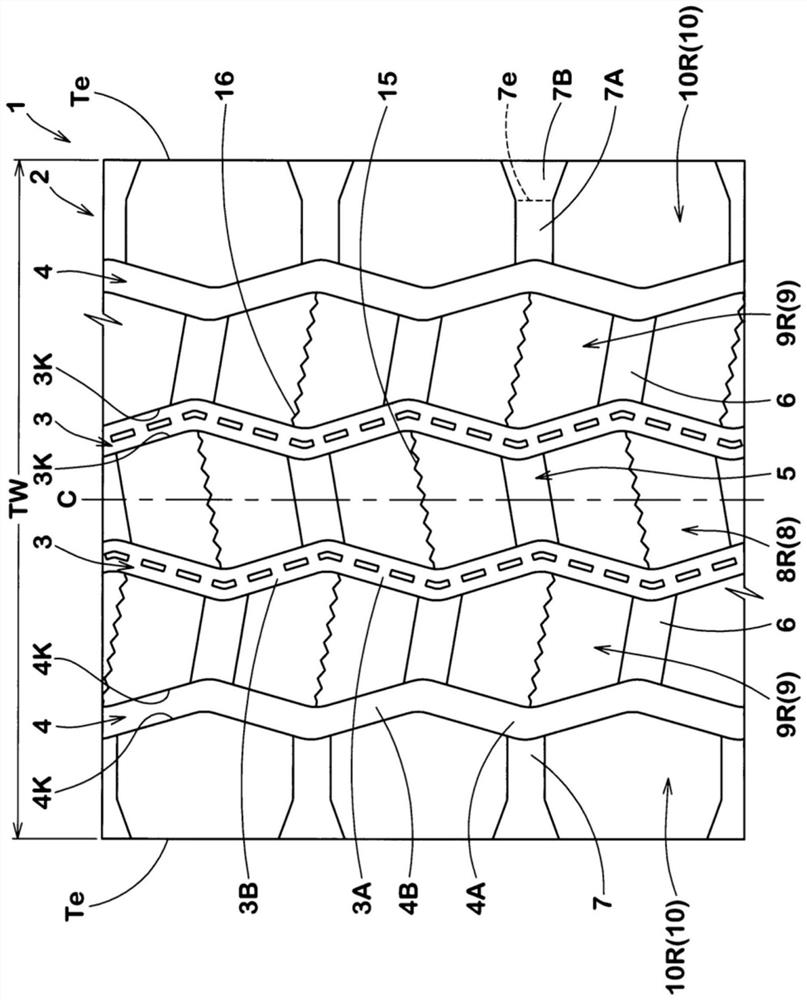

[0030] figure 1 A developed view showing the tread portion 2 of the tire 1 according to one embodiment of the present invention is shown. The tire 1 of the present embodiment can be used in various types of tires, such as pneumatic tires for passenger cars and heavy loads, and non-pneumatic tires in which pressurized air is not filled inside the tire. The tire 1 of the present embodiment is preferably used as a pneumatic tire for heavy loads.

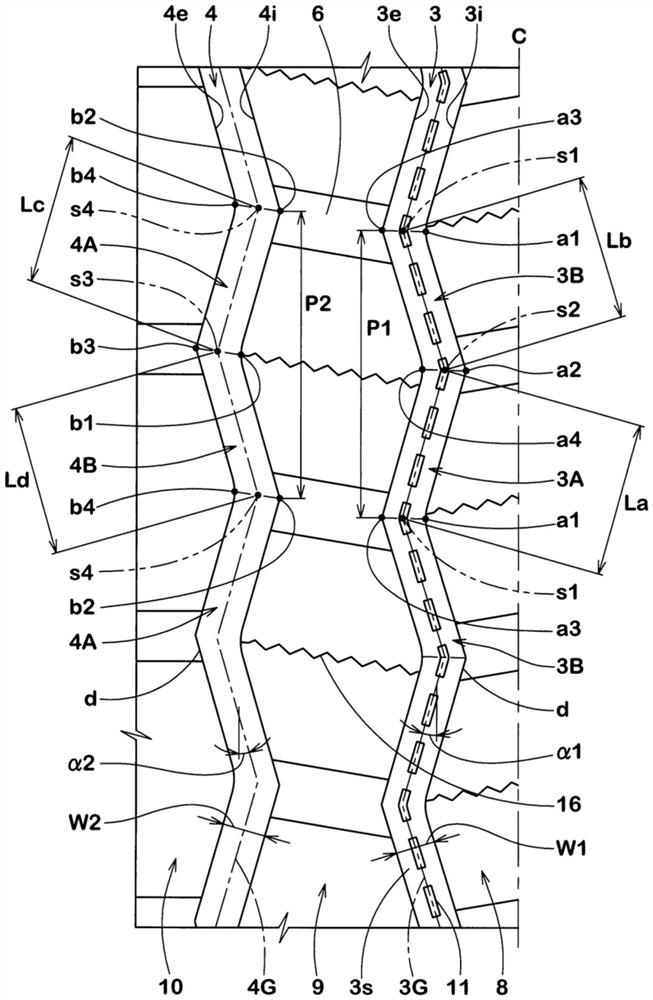

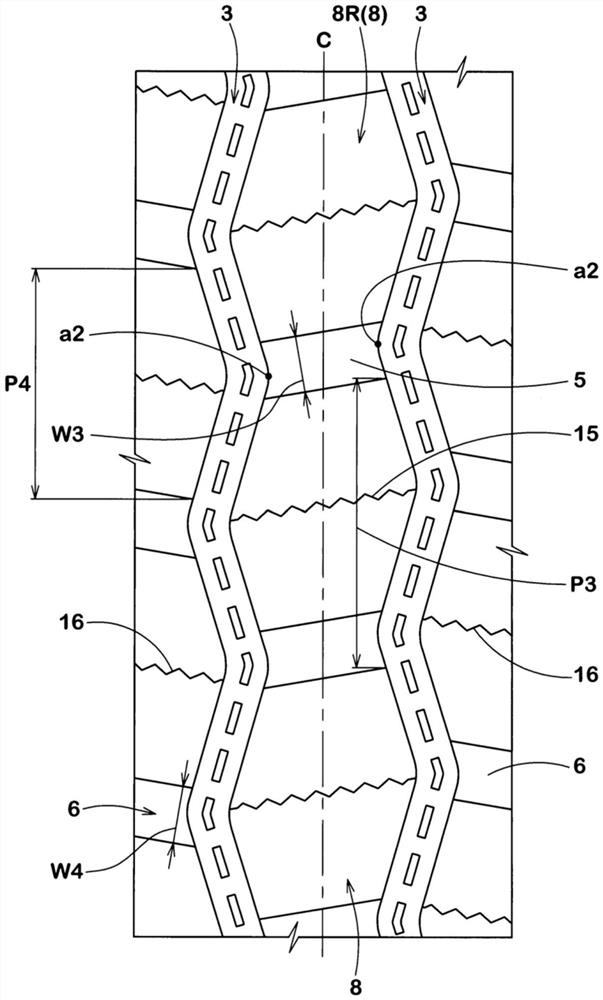

[0031] In the tread portion 2 of the present embodiment, a pair of crown main grooves 3 and 3 extending continuously in the tire circumferential direction on both outer sides of the tire equator C are provided, and a pair of crown main grooves 3 are provided on the outer side of the tire axial direction of the crown main groove 3 along the tire circumferential direction. A pair of shoulder main grooves 4, 4 extending continu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com