Fabric super-hydrophobic surface preparation method

A super-hydrophobic surface and fabric technology, which is applied in the field of fabric super-hydrophobic surface preparation, can solve the problems of poor durability and super-hydrophobic fabrics that cannot satisfy both super-hydrophobicity and water pressure resistance, and achieve excellent chemical stability and mechanical durability. , good water pressure resistance and air permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

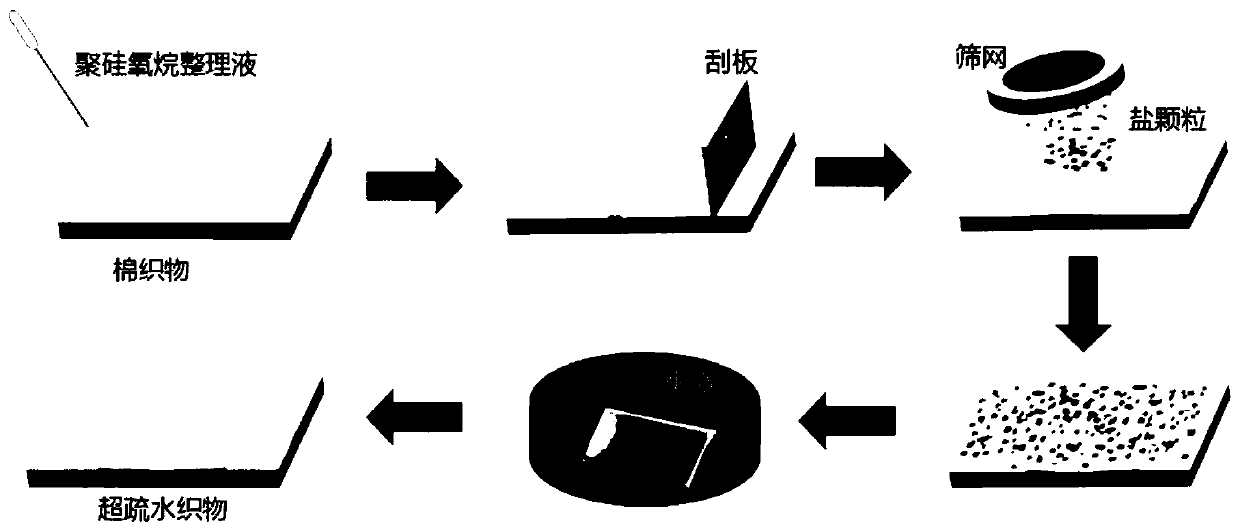

[0043] A kind of preparation method of superhydrophobic surface of cotton fabric:

[0044] Step 1. Measure di-n-octyltin dilaurate and silane coupling agent at a volume ratio of 1:3, and stir and mix for 30 minutes at 25°C and 500 r / min to obtain a crosslinking agent;

[0045] Step 2. Measure polydimethylsiloxane, hydroxyl polydimethylsiloxane and polymethylhydrogensiloxane according to the volume ratio of 2:1:1, and mix them uniformly to obtain a polymethylsiloxane mixture ; Measure the polymethylsiloxane mixture and crosslinking agent according to the volume ratio of 9.5:1, place them in a beaker, stir them magnetically for 20 minutes, and let stand at room temperature for 15 minutes to obtain a polysiloxane finishing solution;

[0046]Step 3, evenly spread the cotton fabric with a size of 5cm*5cm, weigh the polysiloxane finishing liquid according to the mass ratio of the polysiloxane finishing liquid and the cotton fabric at 1.3:1, and take the polysiloxane finishing liquid...

Embodiment 2

[0051] A kind of preparation method of superhydrophobic surface of cotton fabric:

[0052] Step 1. Measure di-n-octyltin dilaurate and silane coupling agent according to the volume ratio of 1:2.5, and stir and mix for 30 minutes at 25°C and 500 r / min to obtain a crosslinking agent;

[0053] Step 2: Measure polydimethylsiloxane, hydroxypolydimethylsiloxane and polymethylhydrogensiloxane according to the volume ratio of 1.8:1:1, and mix them uniformly to obtain a polymethylsiloxane mixture ; Measure the polymethylsiloxane mixture and the crosslinking agent according to the volume ratio of 9:1, place them in a beaker, stir them magnetically for 20 minutes, and let stand at room temperature for 15 minutes to obtain a polysiloxane finishing solution;

[0054] Step 3, spread the cotton fabric with a size of 5cm*5cm evenly, weigh the polysiloxane finishing liquid according to the mass ratio of the polysiloxane finishing liquid and the cotton fabric at 1:1, and mix the polysiloxane T...

Embodiment 3

[0059] A kind of preparation method of superhydrophobic surface of cotton fabric:

[0060] Step 1. Measure di-n-octyltin dilaurate and silane coupling agent according to the volume ratio of 1:3.5, and stir and mix for 30 minutes at 25°C and 500 r / min to obtain a crosslinking agent;

[0061] Step 2. Measure polydimethylsiloxane, hydroxypolydimethylsiloxane and polymethylhydrogensiloxane according to the volume ratio of 2.2:1:1, and mix them uniformly to obtain a polymethylsiloxane mixture ; Measure the polymethylsiloxane mixture and the crosslinking agent according to the volume ratio of 10:1, place them in a beaker, stir them magnetically for 20 minutes, and let stand at room temperature for 15 minutes to obtain a polysiloxane finishing solution;

[0062] Step 3, evenly spread the cotton fabric with a size of 5cm*5cm, weigh the polysiloxane finishing liquid according to the mass ratio of the polysiloxane finishing liquid and the cotton fabric at 1.5:1, and mix the polysiloxane...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com