Mouse cage cast aluminum rotor with low loss

A casting aluminum rotor, low-loss technology, applied in the direction of electrical components, electromechanical devices, asynchronous induction motors, etc., can solve the problems of complex casting aluminum process, difficult industrialization, short mold life, etc., achieve low resistivity, convenient industry The effect of optimizing and controlling product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

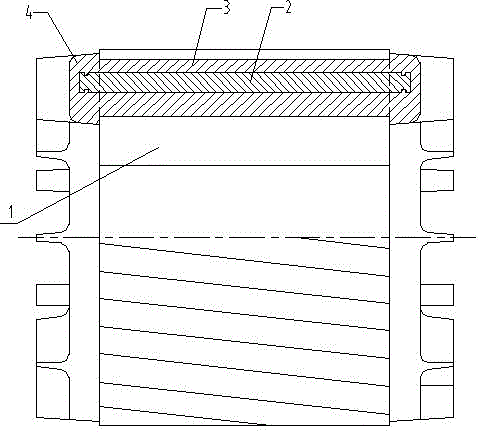

[0013] as attached figure 1 As shown, a low-loss squirrel-cage cast aluminum rotor, the rotor 1 is formed by stacking rotor punches, and the punching grooves on each rotor punch are superimposed to form rotor slots (attached figure 1 The rotor slot in the rotor is filled with cast aluminum guide bars and copper guide bars), copper guide bars 2 are embedded in the rotor slot, and the gap between copper guide bars 2 and the rotor slot is formed by casting aluminum guide bars 3.

[0014] As shown in Figure 1, the length of the copper guide bar 2 is greater than the length of the rotor formed by stacking the rotor punches, and the protruding parts at both ends of the copper guide bar are wrapped with aluminum to form the rotor end ring 4.

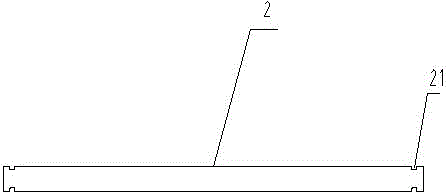

[0015] as attached figure 2 As shown, in order to increase the contact area between the end of the copper guide bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com