Compact 35kv side structure of 500kv main transformer

A compact, transformer technology, used in substations, non-enclosed substations, enclosed substations, etc., can solve the problems of occupying land area, large area, large size, etc., to save area, low failure probability, flash The effect of low network probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

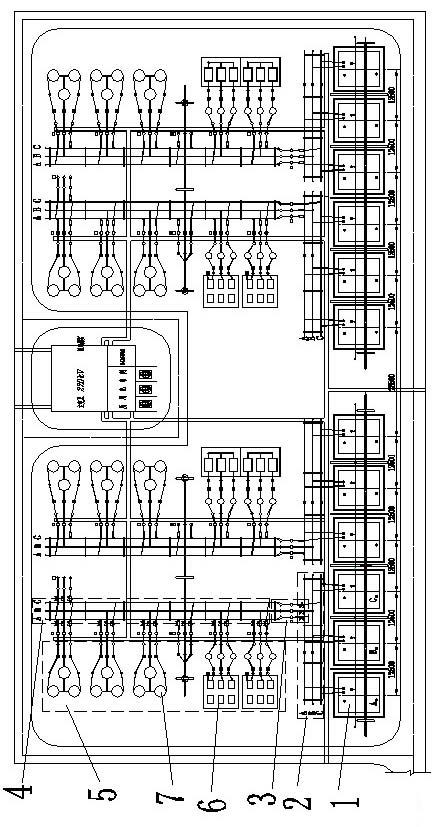

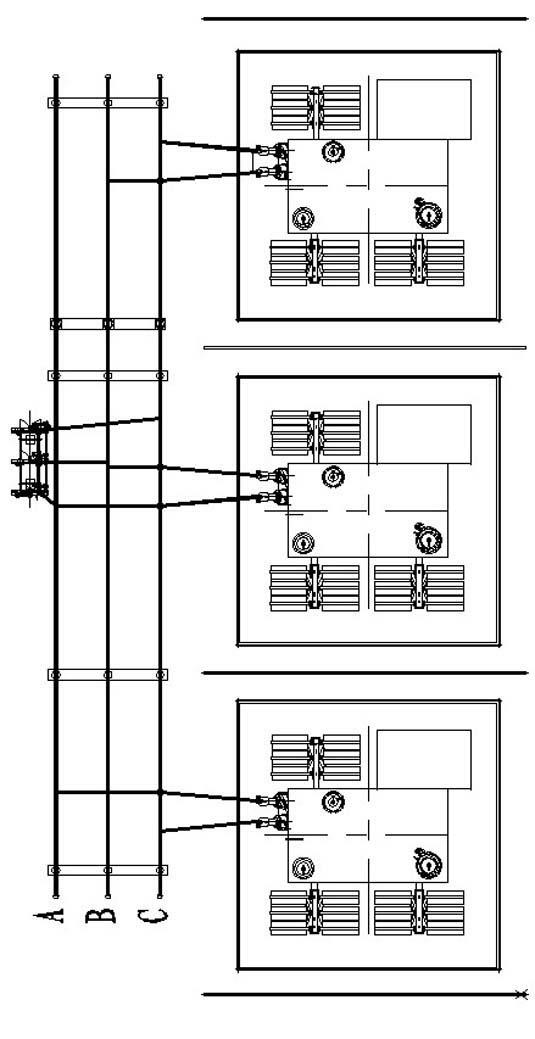

[0071] like Figure 9 As shown, the present invention comprises A, B, C three-phase transformer 1, and three-phase transformer 1 connects total circuit 3 through △ bus 2, and total circuit 3 connects 35kv bus 4, and 35kv bus 4 connects each branch circuit 5, and above-mentioned branch circuit It includes a capacitive branch circuit 6 and a reactance branch circuit 7 . The capacitance branch circuit 6 includes a parallel capacitor bank 8 and a series reactor 9 connected to the parallel capacitor bank 8 ; the reactance branch circuit 7 includes a three-phase reactor 10 . In order to realize the compact design, the present invention adopts the dry-type insulated bus bar 2 to complete the △ winding; in the capacitance branch circuit 6, the A, B, and C three-phases in each parallel capacitor bank are superimposed and placed; in the reactance branch circuit In 7, the reactor 10 is a stacked dry-type shunt air-core reactor or a magnetic shield shunt reactor, which will be specifical...

Embodiment 2

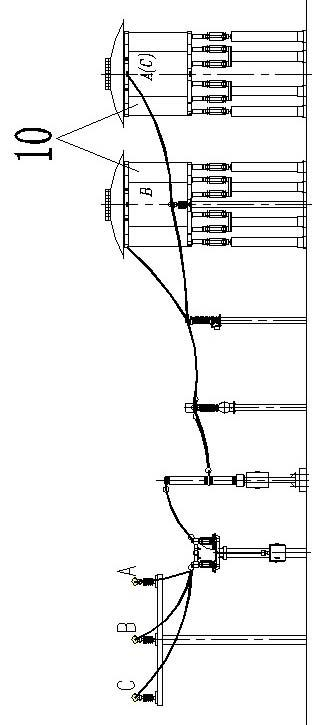

[0088] The difference between this embodiment and Embodiment 1 is that in the reactance branch circuit 7 of this embodiment, as Figure 14 As shown, the stacked dry-type shunt air-core reactor refers to: A, B, C three-phase reactors are stacked up and down, and reactance post insulators 13 are arranged between adjacent two-phase reactors.

Embodiment 3

[0090] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that in the reactance branch circuit 7 of this embodiment, a magnetically shielded shunt reactor is used.

[0091] like Figure 15 --As shown in 18, this embodiment includes reactors connected in parallel with three phases A, B, and C. Each of the above-mentioned reactors is composed of upper and lower sections, and the upper and lower sections of each phase reactor are connected through a star The frame 12 is connected; and the wire package 16 of each section of reactor is provided with a high-permeability magnetic core inside and outside.

[0092] It should be noted that the structure of the upper and lower parts of each phase reactor is basically the same, which is a concentric circle structure composed of multi-layer wire wraps. The inner iron core 17 and the outer iron core 18 are arranged inside and outside, so that the reluctance of the reactor is greatly reduced, and at the same time it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com