Self-supporting prefabricated column hybrid connection and construction method thereof

A hybrid connection and construction method technology, applied in the direction of columns, pier columns, pillars, etc., can solve the problems that the design method is not mature enough, and it is difficult to further take advantage of the speed advantage of prefabricated buildings, so as to achieve convenient engineering design and application, high construction efficiency, Reduce the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

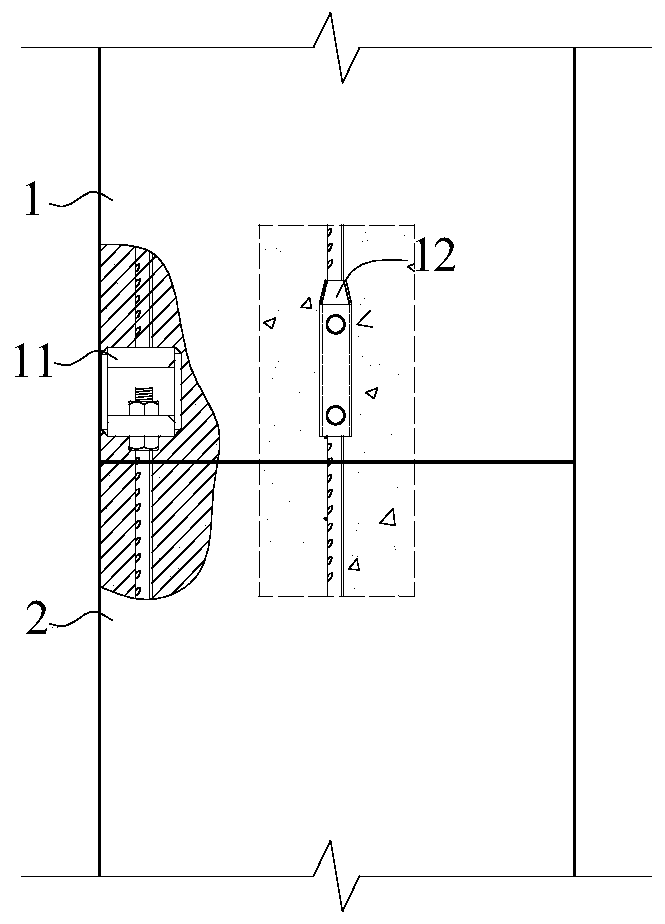

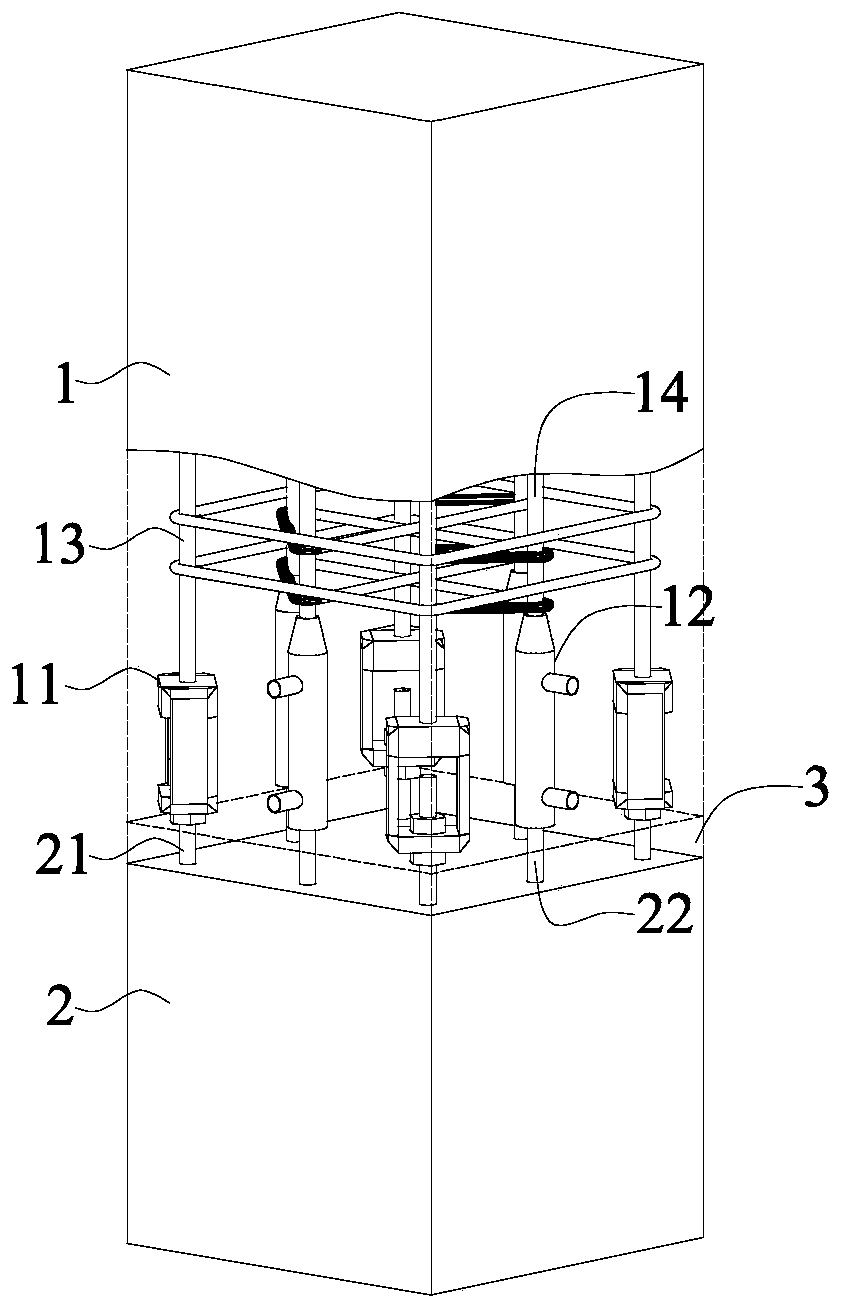

[0029] like Figures 1 to 2 , the four bolt connectors 11 are respectively at the corners of the upper prefabricated column 1, the four sleeves 12 are respectively at the middle position of the side of the upper prefabricated column 1, the bolt connectors 11, the sleeve 12 and the lower end surface of the upper prefabricated column 1 on the same plane. The upper prefabricated column 1 also has a first longitudinal steel bar 13 and a second longitudinal steel bar 14. The first longitudinal steel bar 13 is connected with the bolt connector 11 through an internal thread, and the second longitudinal steel bar 14 is connected with the sleeve 12 through an internal thread. There are third longitudinal reinforcement bars 21 and fourth longitudinal reinforcement bars 22 in the lower prefabricated column 2 .

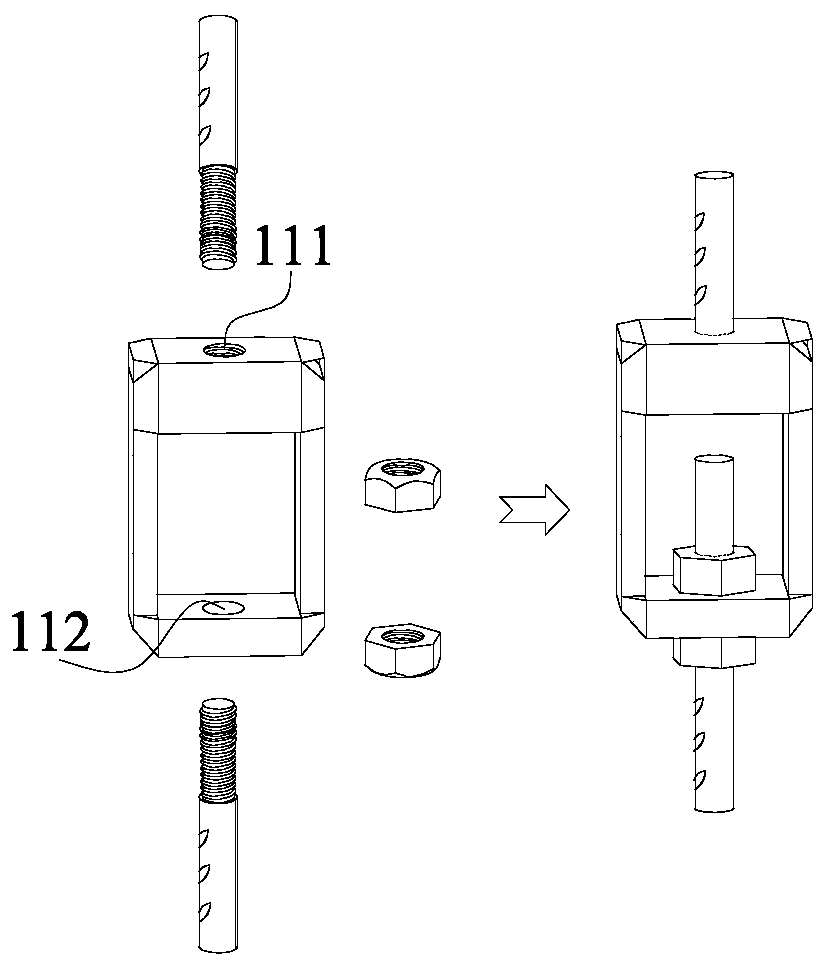

[0030] like image 3 , the top center of the bolt connector 11 has a bolt connector inner threaded hole 111, and the bottom center has a bolt connector bottom plate hole 112. ...

Embodiment 2

[0040] like Figure 5 , the four bolt connectors 11 are respectively at the corners of the upper prefabricated column 1, the four sleeves 12 are respectively in the middle of the side surface of the upper prefabricated column 1, the bolt connectors 11, the sleeve 12 and the lower end surface of the upper prefabricated column 1 on the same plane. The upper prefabricated column 1 also has a first longitudinal steel bar 13 and a second longitudinal steel bar 14. The first longitudinal steel bar 13 is fixedly connected with the bolt connector 11 through nuts, and the second longitudinal steel bar 14 is connected with the sleeve 12 through internal threads. There are third longitudinal reinforcement bars 21 and fourth longitudinal reinforcement bars 22 in the lower prefabricated column 2 .

Embodiment 3

[0042] like Image 6 , the four bolt connectors 11 are respectively at the corners of the upper prefabricated column 1, the four sleeves 12 are respectively in the middle of the side surface of the upper prefabricated column 1, the bolt connectors 11, the sleeve 12 and the lower end surface of the upper prefabricated column 1 on the same plane. The upper prefabricated column 1 also has a first longitudinal steel bar 13 and a second longitudinal steel bar 14. The first longitudinal steel bar 13 and the bolt connector 11 are connected by internal threads, and the second longitudinal steel bar 14 and the sleeve 12 are filled with high-strength grouting material. connect. There are third longitudinal reinforcement bars 21 and fourth longitudinal reinforcement bars 22 in the lower prefabricated column 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com