Preparation method of high-purity tungsten plate easy to machine

A mechanical processing, high-purity technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of difficult mechanical processing, high brittleness of chemical vapor deposition, etc., to achieve improved processing performance, high density , thickness controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of tungsten slabs by chemical vapor deposition: In a closed reaction chamber at atmospheric pressure, hydrogen and tungsten hexafluoride were used as raw materials to deposit a tungsten plate with a thickness of 10 mm on the surface of a copper substrate at a temperature of 600 °C; hydrogen and tungsten hexafluoride The purity of tungsten hexafluoride is greater than 99.99 wt.%, and the purity of the obtained tungsten plate is greater than 99.99999%.

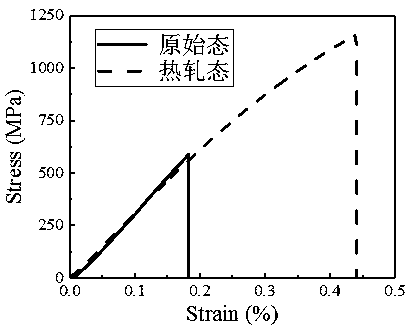

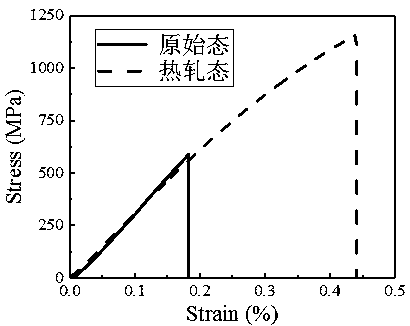

[0028] (2) Rolling: The tungsten slab obtained in step (1) was heated to 1550°C in a hydrogen atmosphere, annealed for 60 min, and the processing rate was controlled to 37% for the first pass of rolling, followed by tempering at 1500°C for 45 min; controlled processing rate 23% for the second rolling pass, followed by tempering at 1450°C for 45 min; controlled processing rate 22% for the third pass rolling, followed by tempering at 1400°C for 45 min; controlled processing The rate is 24% for the fourth pas...

Embodiment 2

[0032] (1) Preparation of tungsten slabs by chemical vapor deposition: In a closed reaction chamber at atmospheric pressure, hydrogen and tungsten hexafluoride were used as raw materials to deposit a tungsten plate with a thickness of 40 mm on the surface of a copper substrate at a temperature of 500 °C; hydrogen and tungsten hexafluoride The purity of tungsten hexafluoride is greater than 99.99 wt.%, and the purity of the obtained tungsten plate is greater than 99.99999%.

[0033] (2) Rolling: Heat the tungsten slab obtained in step (1) to 1500°C in a hydrogen atmosphere, anneal for 30 minutes, and control the processing rate to 30% for the first rolling pass, and then temper at 1470°C for 30 minutes min; controlled processing rate was 20% for the second rolling pass, followed by tempering at 1440°C for 30 min; controlled processing rate was 22% for the third pass rolling, followed by tempering at 1410°C for 30 min; controlled processing The rate is 25% for the fourth pass ro...

Embodiment 3

[0036] (1) Preparation of tungsten slabs by chemical vapor deposition: In a sealed reaction chamber at atmospheric pressure, hydrogen and tungsten hexafluoride were used as raw materials to deposit a tungsten plate with a thickness of 20 mm on the surface of a copper substrate at a temperature of 550 °C; hydrogen and tungsten hexafluoride The purity of tungsten hexafluoride is greater than 99.99 wt.%, and the purity of the obtained tungsten plate is greater than 99.99999%.

[0037] (2) Rolling: Heat the tungsten slab obtained in step (1) to 1520°C in a hydrogen atmosphere, anneal for 60 minutes, control the processing rate to 40% for the first rolling pass, and then temper at 1480°C for 60 minutes min; controlled processing rate was 20% for the second rolling pass, followed by tempering at 1440°C for 60 min; controlled processing rate was 23% for the third pass rolling, followed by tempering at 1400°C for 60 min; controlled processing The rate is 25% for the fourth pass rollin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| bending stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com