Staged heating, extruding and form-controlling method of powder superalloy component

A high-temperature alloy, stage heating technology, applied in the improvement of powder superalloy component preparation process, stage heating extrusion shape control field, can solve the problems of long preparation cycle, low material utilization rate, complex process, etc., to reduce blank processing waste Quantity, improve material utilization, reduce the effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

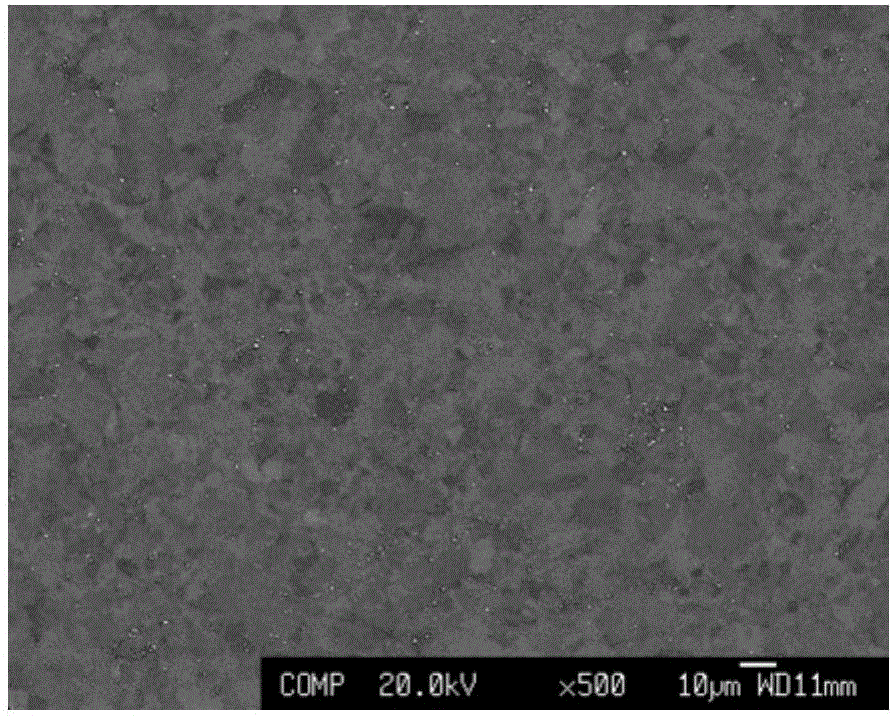

Embodiment 1

[0044]The step-by-step heating extrusion shape control method for powder superalloy components is characterized in that the steps of the method are:

[0045] Step 1. Powder preparation

[0046] Calculate and weigh 7kg of atomized superalloy powder according to the size of the component, and the weighed weight is calculated according to the following formula:

[0047] m 装载 = m 计算 / 0.8 Formula 1

[0048] In the formula: m 装载 is the weight of the atomized superalloy powder loaded into the mold, m 计算 is the atomized superalloy powder weight calculated according to the volume of the component;

[0049] Step 2. Extrusion mold preparation

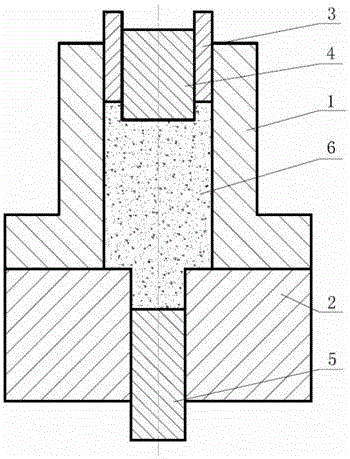

[0050] A steel material with a breaking strength exceeding 2000 MPa is used to prepare an extrusion die. The die consists of an upper ring die 1 and a lower ring die 2 to form an extrusion die cavity, wherein the lower ring die 2 is fixed on the lower workbench of the press, and the upper ring die 2 is fixed on the lower workbench of the pre...

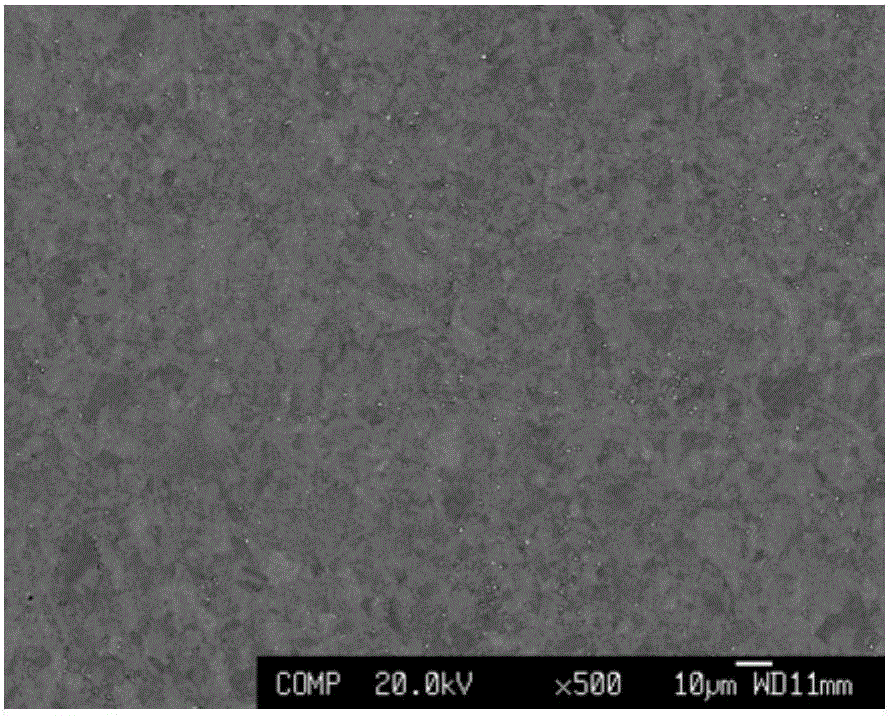

Embodiment 2

[0068] The step-by-step heating extrusion shape control method for powder superalloy components is characterized in that the steps of the method are:

[0069] Step 1. Powder preparation

[0070] Calculate and weigh 5kg of atomized superalloy powder according to the size of the component, and the weighed weight is calculated according to the following formula:

[0071] m 装载 = m 计算 / 0.8 Formula 1

[0072] In the formula: m 装载 is the weight of the atomized superalloy powder loaded into the mold, m 计算 is the atomized superalloy powder weight calculated according to the volume of the component;

[0073] Step 2. Extrusion mold preparation

[0074] A steel material with a breaking strength exceeding 2000 MPa is used to prepare an extrusion die. The die consists of an upper ring die 1 and a lower ring die 2 to form an extrusion die cavity, wherein the lower ring die 2 is fixed on the lower workbench of the press, and the upper ring die 2 is fixed on the lower workbench of the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com