Method for producing X65 pipe steel with low cost

A pipeline steel, low-cost technology, applied in temperature control, metal rolling, etc., to achieve the effect of promoting recrystallization, improving utilization rate, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Process route: electric furnace smelting → LF furnace refining → thin slab continuous casting (slab thickness 60mm) → continuous casting slab soaking → high pressure water descaling → controlled rolling → controlled cooling → coiling.

[0031] Chemical composition of molten steel: C: 0.046%, Si: 0.30%, Mn: 1.40%, P: 0.015%, S: 0.008%, Nb: 0.045%, Ti: 0.025%, N: 0.007%.

[0032] Continuous casting and hot rolling process: continuous casting casting speed: 4.8m / min, slab entering furnace temperature: 1050°C, furnace exit temperature: 1170°C, starting rolling temperature: 1080°C, final rolling temperature: 880°C, strong cooling mode, Coiling temperature: 620°C.

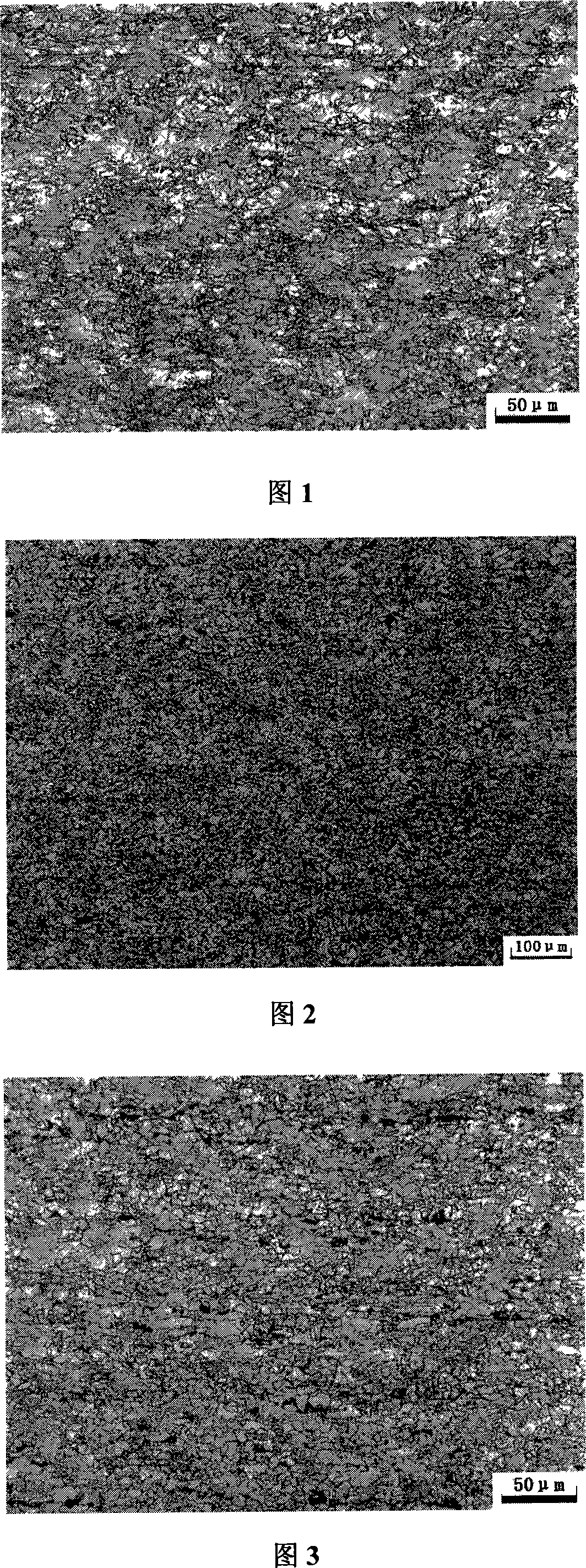

[0033] The structure of the steel strip is shown in Figure 1, and the grain size and properties of the steel strip are shown in Table 1.

[0034] Grain size and performance of table 1 embodiment 1 steel strip

[0035] Strip thickness

[0036] Note: Tensile, cold bending and impact are all taken transve...

Embodiment 2

[0038] Process route: electric furnace smelting → LF furnace refining → thin slab continuous casting (slab thickness 60mm) → continuous casting slab soaking → high pressure water descaling → controlled rolling → controlled cooling → coiling.

[0039] Chemical composition of molten steel: C: 0.053%, Si: 0.20%, Mn: 1.50%, P: 0.012%, S: 0.005%, Nb: 0.048%, Ti: 0.020%, N: 0.006%.

[0040] Continuous casting and hot rolling process: continuous casting casting speed: 4.5m / min, slab entering furnace temperature: 990°C, furnace exit temperature: 1180°C, starting rolling temperature: 1110°C, final rolling temperature: 860°C, strong cooling mode, Coiling temperature: 580°C. The structure of the steel strip is shown in Figure 2, and the grain size and properties of the steel strip are shown in Table 2.

[0041] Grain size and performance of table 2 embodiment 2 steel strip

[0042]

[0043]Note: Tensile, cold bending and impact are all taken transversely; the impact sample si...

Embodiment 3

[0045] Process route: electric furnace smelting → LF furnace refining → thin slab continuous casting (slab thickness 60mm) → continuous casting slab soaking → high pressure water descaling → controlled rolling → controlled cooling → coiling.

[0046] Chemical composition of molten steel: C: 0.060%, Si: 0.15%, Mn: 1.60%, P: 0.006%, S: 0.001%, Nb: 0.050%, Ti: 0.015%, N: 0.005%.

[0047] Continuous casting and hot rolling process: continuous casting casting speed: 4.0m / min, slab entering furnace temperature: 980°C, furnace exit temperature: 1200°C, starting rolling temperature: 1130°C, final rolling temperature: 840°C, strong cooling mode, Coiling temperature: 540°C.

[0048] The structure of the steel strip is shown in Figure 3, and the grain size and properties of the steel strip are shown in Table 3.

[0049] Grain size and performance of table 3 embodiment 3 steel strip

[0050]

[0051] Note: Tensile, cold bending and impact are all taken transversely; the impact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com