Synthetic jet actuator with double films, single chamber and single spout

A technology of synthetic jet and single nozzle, applied in the aerospace field, can solve the problem of low energy conversion ability, and achieve the effect of improving the ability of kinetic energy, improving stall characteristics, and improving the ability of energy conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

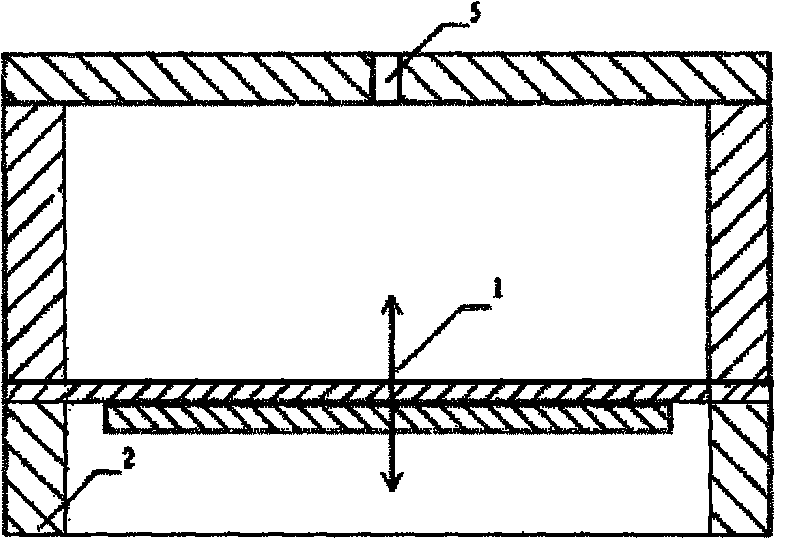

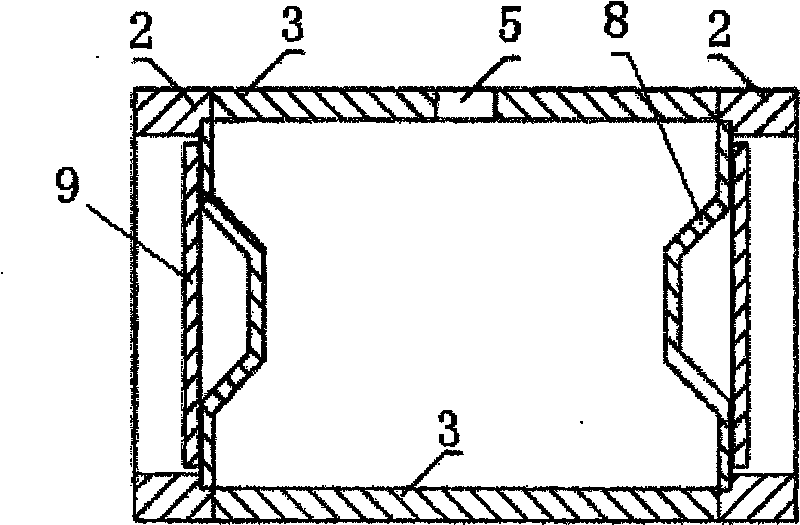

[0023] This embodiment includes two membrane supports 2, two bow-shaped vibrating membranes 6, a box body 3 and two pairs of electrode wires, and the outer edges of the two bow-shaped vibrating membranes 6 are bonded and fixed on the mounting surface at one end of the inner hole of the membrane bracket 2 respectively. 4 on. The two membrane supports 2 on which the bow-shaped vibrating membrane 6 is fixed are respectively located at both ends of the box body 3 and are fixedly connected with the box body.

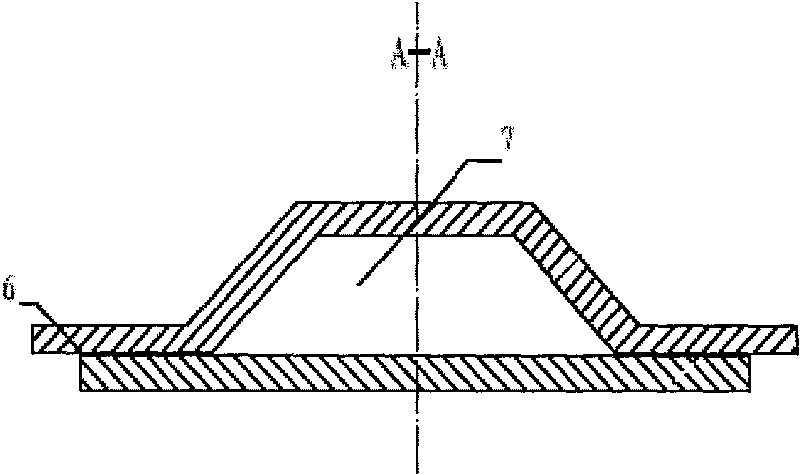

[0024] The bow-shaped vibrating film 6 includes a PZT ceramic sheet 9 and a copper foil sheet 8 . The PZT ceramic sheet 9 is a circular sheet whose outer diameter is smaller than the inner diameter of the membrane support 2 . The copper foil 8 is circular, and its outer diameter is the same as the mounting surface of the stepped arcuate vibrating film 6 on the inner hole of the support 2; the center of the copper foil is a protruding trapezoidal platform. The end surface of...

Embodiment 2

[0029] This embodiment includes two membrane supports 2, two bow-shaped vibrating membranes 6, a box body 3 and two pairs of electrode wires, and the outer edges of the two bow-shaped vibrating membranes 6 are bonded and fixed on the mounting surface at one end of the inner hole of the membrane bracket 2 respectively. 4 on. The two membrane supports 2 on which the bow-shaped vibrating membrane 6 is fixed are respectively located at both ends of the box body 3 and are fixedly connected with the box body.

[0030] The bow-shaped vibrating film 6 includes a PZT ceramic sheet 9 and a copper foil sheet 8 . The PZT ceramic sheet 9 is a circular sheet whose outer diameter is smaller than the inner diameter of the membrane support 2 . The copper foil 8 is circular, and its outer diameter is the same as the mounting surface of the stepped arcuate vibrating film 6 on the inner hole of the support 2; the center of the copper foil is a protruding trapezoidal platform. The end surface of...

Embodiment 3

[0035] This embodiment includes two membrane supports 2, two bow-shaped vibrating membranes 6, a box body 3 and two pairs of electrode wires, and the outer edges of the two bow-shaped vibrating membranes 6 are bonded and fixed on the mounting surface at one end of the inner hole of the membrane bracket 2 respectively. 4 on. The two membrane supports 2 on which the bow-shaped vibrating membrane 6 is fixed are respectively located at both ends of the box body 3 and are fixedly connected with the box body.

[0036] The bow-shaped vibrating film 6 includes a PZT ceramic sheet 9 and a copper foil sheet 8 . The PZT ceramic sheet 9 is a circular sheet whose outer diameter is smaller than the inner diameter of the membrane support 2 . The copper foil 8 is circular, and its outer diameter is the same as the mounting surface of the stepped arcuate vibrating film 6 on the inner hole of the support 2; the center of the copper foil is a protruding trapezoidal platform. The end surface of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com