Gradient curvature raised roller of tension leveler for cogged ingot continuous casting and use method

A tension leveler and bloom technology, which is applied in the field of bloom continuous casting production, can solve problems such as stress concentration and cracks in the corners of the billet, and achieve the effects of stable feeding, increasing deformation, and avoiding thermal stress concentration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

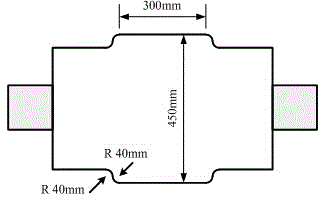

[0025] The gradual curvature convex roll of the tension leveler of this embodiment is applied to a 280mm×325mm bloom continuous caster in a steel plant. The 7 tension leveler is used for light reduction. The specific steel types produced are cord steel, bearing steel, etc. Mainly high-carbon alloy steel.

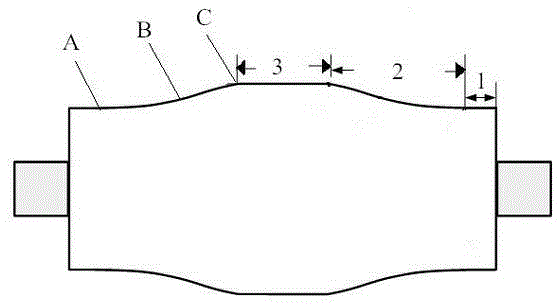

[0026] The structure of the gradual curvature convex roll of the stretch-leveling machine for bloom continuous casting of this embodiment is as follows figure 2 As shown, it is composed of a roller shaft and a roller body, wherein the roller body is composed of an edge zone 1, a gradient curvature zone 2 and a flat roller zone 3. The edge zone 1 is between the edge of the roller body and the arc starting position Area, the gradual curvature area 2 is the area from the starting position to the end arc position, the flat roller area 3 is the area formed between two symmetrically distributed end arc positions on the roller body; The curvature transition zone described is compose...

Embodiment 2

[0035] The gradual curvature convex roll of the tension leveler of this embodiment is applied to a 280mm×325mm bloom continuous caster in a steel plant. The 7 tension leveler is used for light reduction. The specific steel types produced are cord steel, bearing steel, etc. Mainly high-carbon alloy steel.

[0036] The structure of the gradual curvature convex roll of the stretch-leveling machine for bloom continuous casting of this embodiment is as follows figure 2 As shown, it is composed of a roller shaft and a roller body, wherein the roller body is composed of an edge zone 1, a gradient curvature zone 2 and a flat roller zone 3. The edge zone 1 is between the edge of the roller body and the arc starting position Area, the gradual curvature area 2 is the area from the starting position to the end arc position, the flat roller area 3 is the area formed between two symmetrically distributed end arc positions on the roller body; The curvature transition zone described is compose...

Embodiment 3

[0045] The gradual curvature convex roll of the tensile straightening machine of this embodiment is applied to a 380mm×490mm bloom continuous caster in a steel plant. There are 12 tensile straightening machines, of which 10 can be pressed down straightening machines to produce bearing steel and cold heading. Steel and other medium and high-carbon alloy steels are mainly used.

[0046] The structure of the gradual curvature convex roll of the stretch-leveling machine for bloom continuous casting of this embodiment is as follows figure 2 As shown, it is composed of a roller shaft and a roller body, wherein the roller body is composed of an edge zone 1, a gradient curvature zone 2 and a flat roller zone 3. The edge zone 1 is between the edge of the roller body and the arc starting position Area, the gradual curvature area 2 is the area from the starting position to the end arc position, the flat roller area 3 is the area formed between two symmetrically distributed end arc position...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com